Thin-walled bearing component, produced without material-removing machining

a technology of thin-walled bearings and machining, which is applied in the direction of couplings, heat treatment devices, furnaces, etc., can solve the problem that the cold-rolled strip is unlikely to corrode, and achieve the effect of high-beneficial effect on the dimensional stability of the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

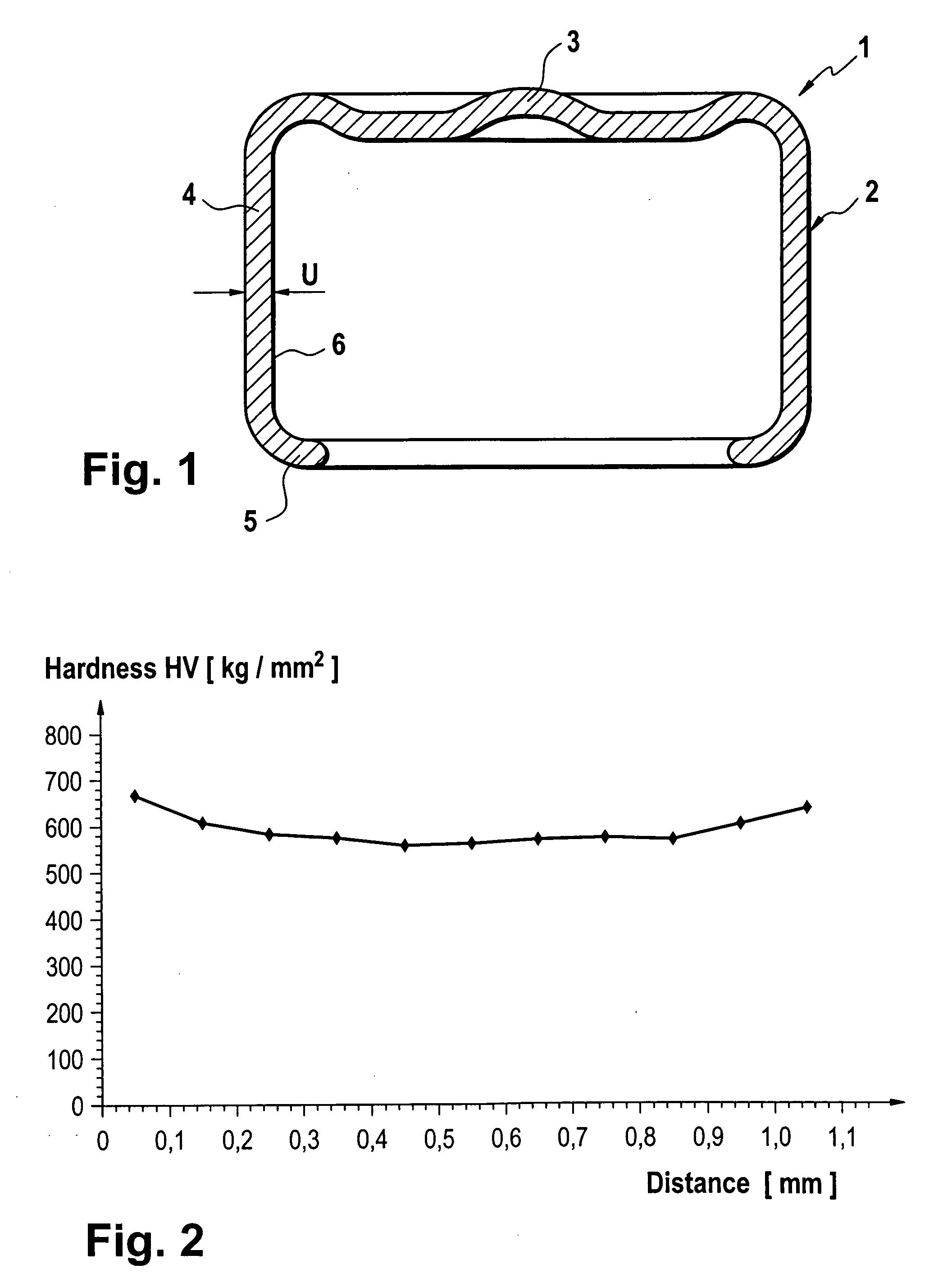

[0025]FIG. 1 shows a sectional view through a bearing component 1 according to the invention in the exemplary form of a universal joint bush 2. This is a rotationally symmetrical component comprising a bush base 3, a bush wall 4 and a flange 5. The universal joint bush is initially deep-drawn from a cold-rolled strip, without the flanged edge 5 yet being provided. This means that the cylinder wall 4 extends in a straight line. After the introduction of needle bearing bodies, the free edge is bent over to form the flanged edge, by means of which the needles are then held in place.

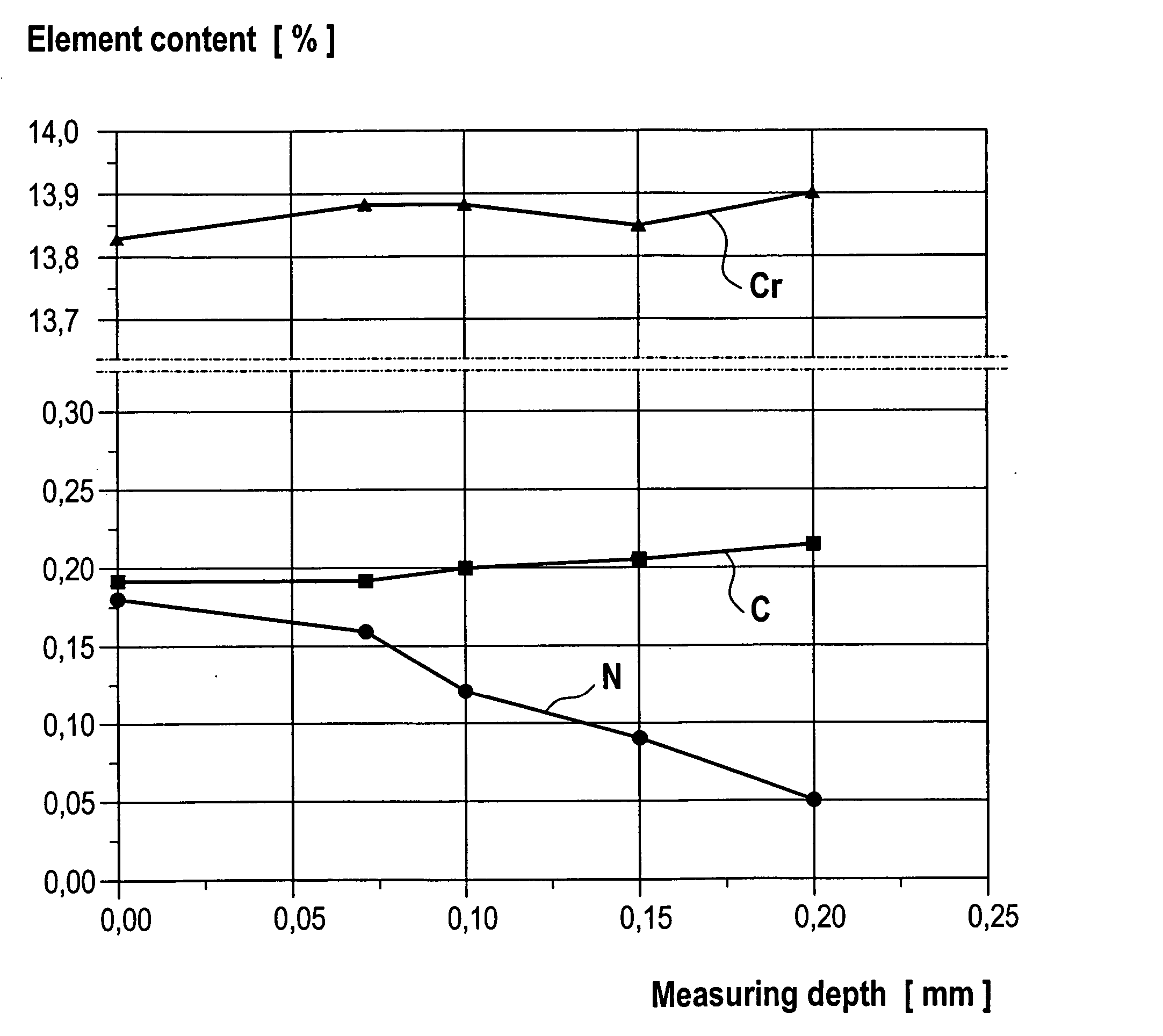

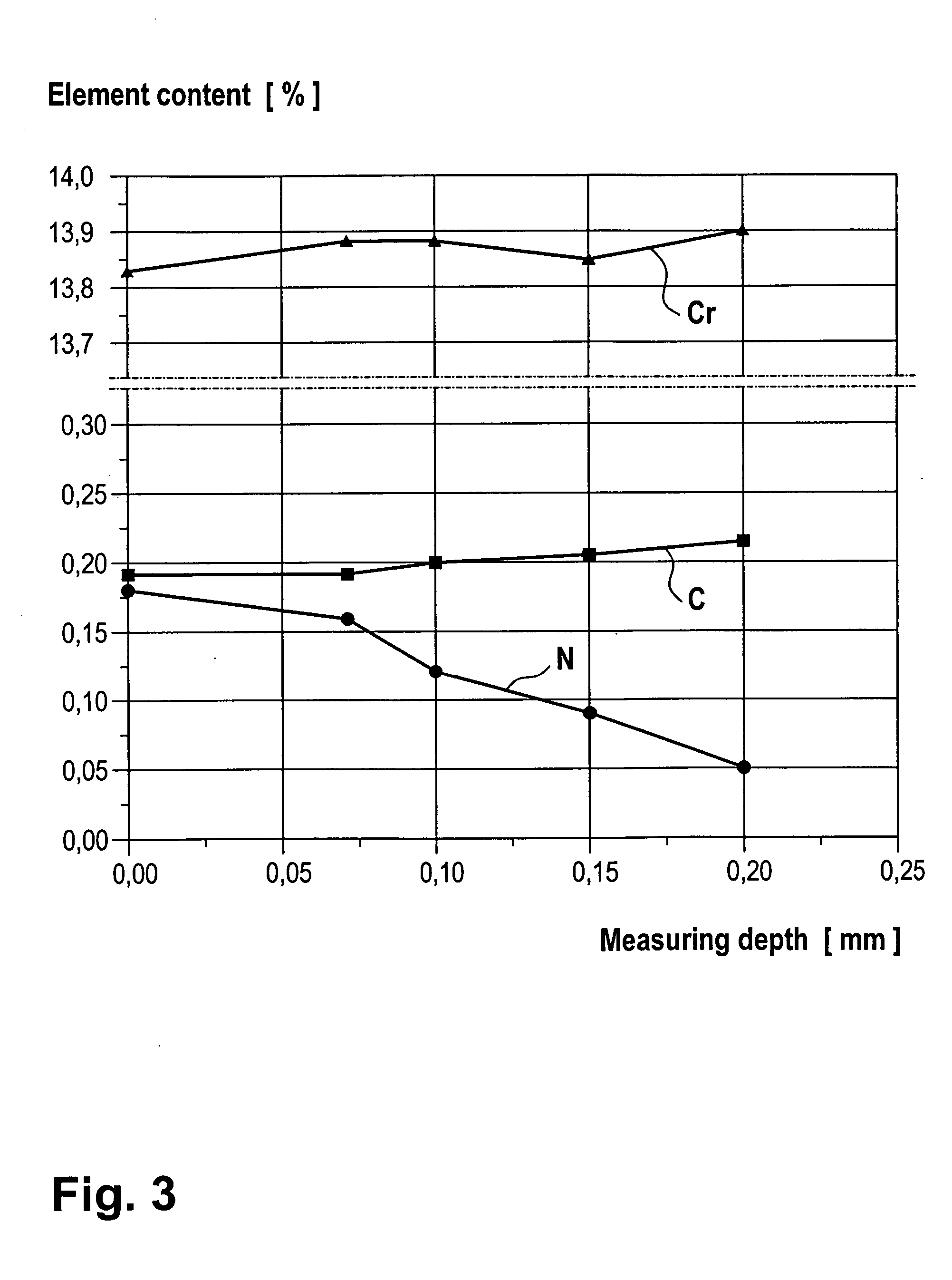

[0026] The universal joint bush 2 is drawn from a cold-rolled strip which has a carbon content of 0.15-0.25% with a chromium alloying content of at least 12%. Known cold-rolled strips which can be used and have these contents as well as isotropic deformation properties, which ensure a homogeneous wall thickness in the drawn component, include, for example, X20Cr13 or X22Cr13. Both are high-alloy steels with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com