Hydrogen storage container and mixture therein

a technology of hydrogen storage containers and hydrogen storage mixtures, which is applied in the directions of transportation and packaging, separation processes, and packaged goods types, etc., can solve the problems of difficult heat transfer into/out of hydride beds, poor conductivity of hydrogen storage alloys, and the hydrogen-absorbing method, so as to increase the thermal conductivity of solid beds and large surface area , good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

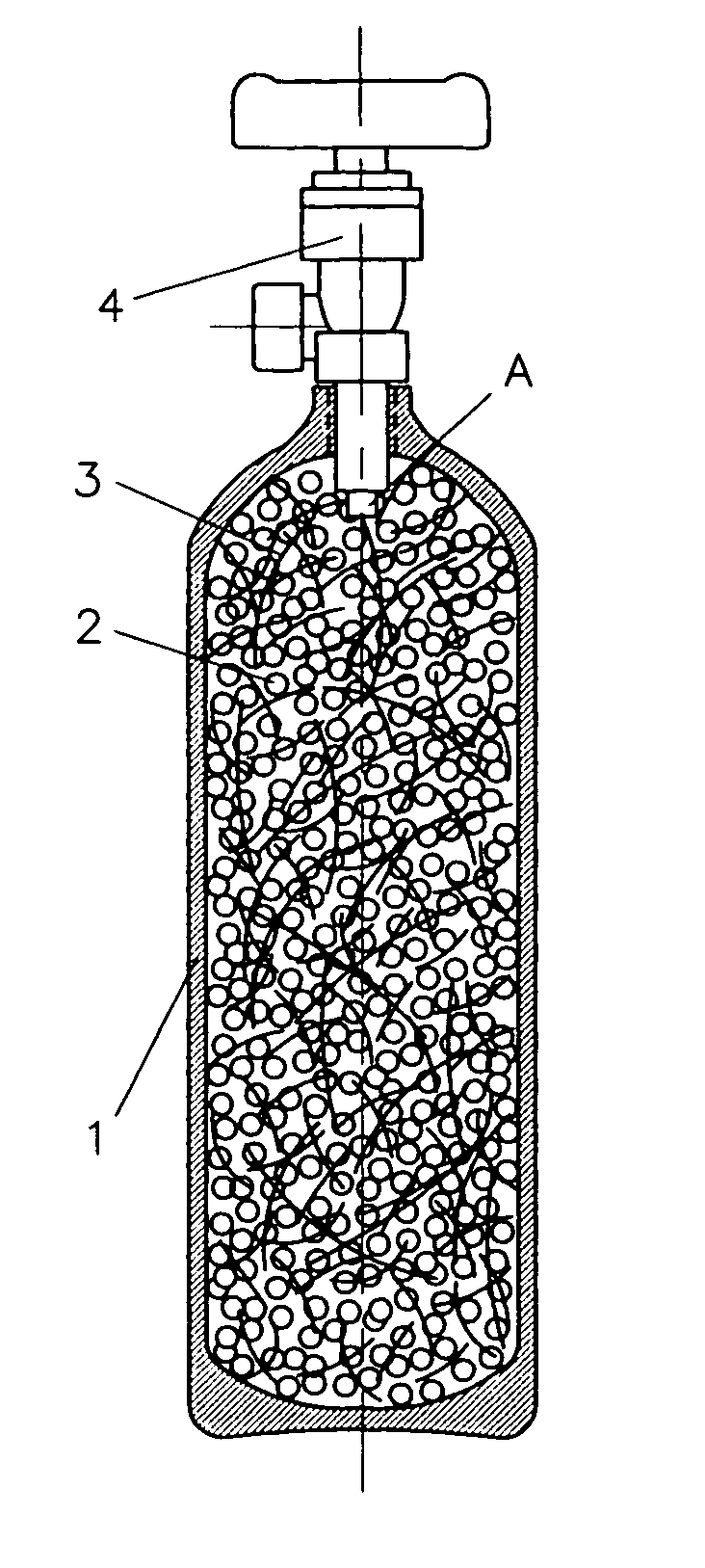

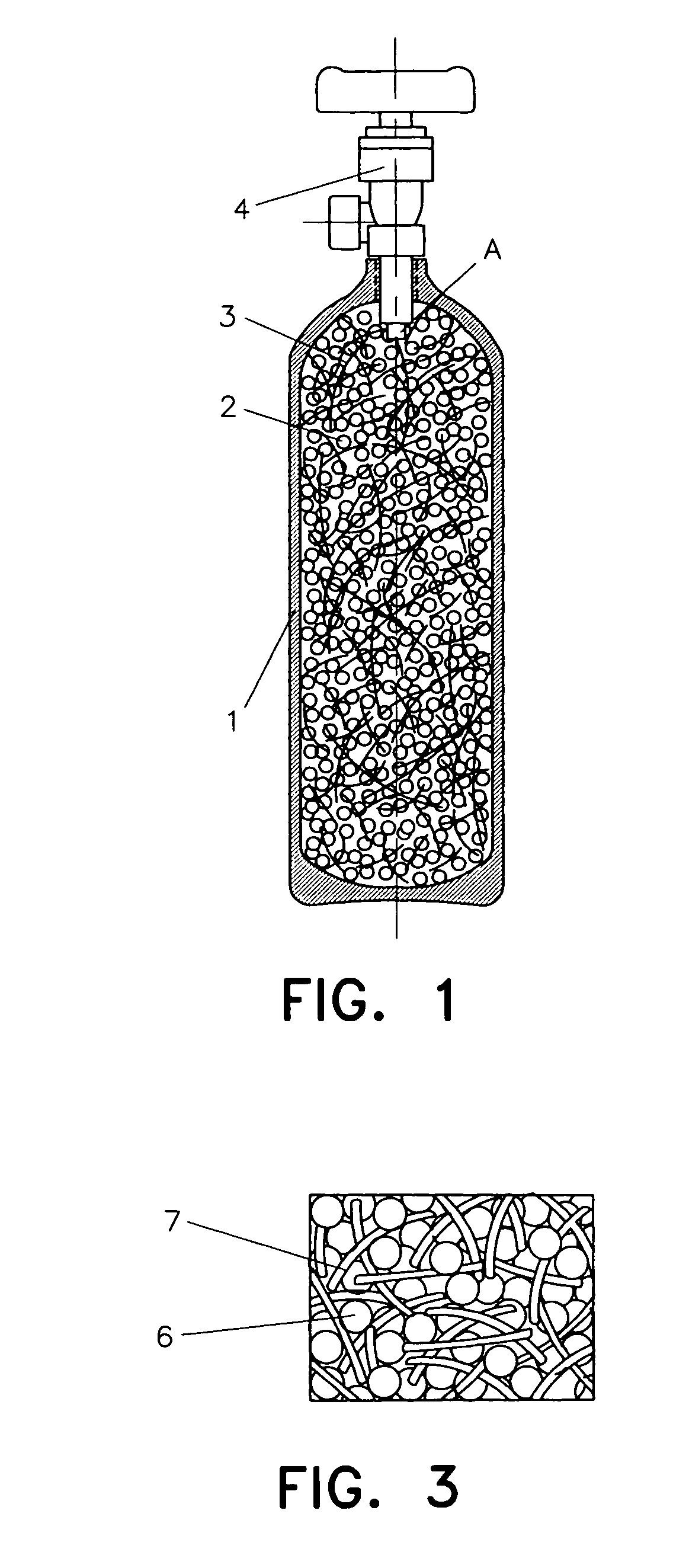

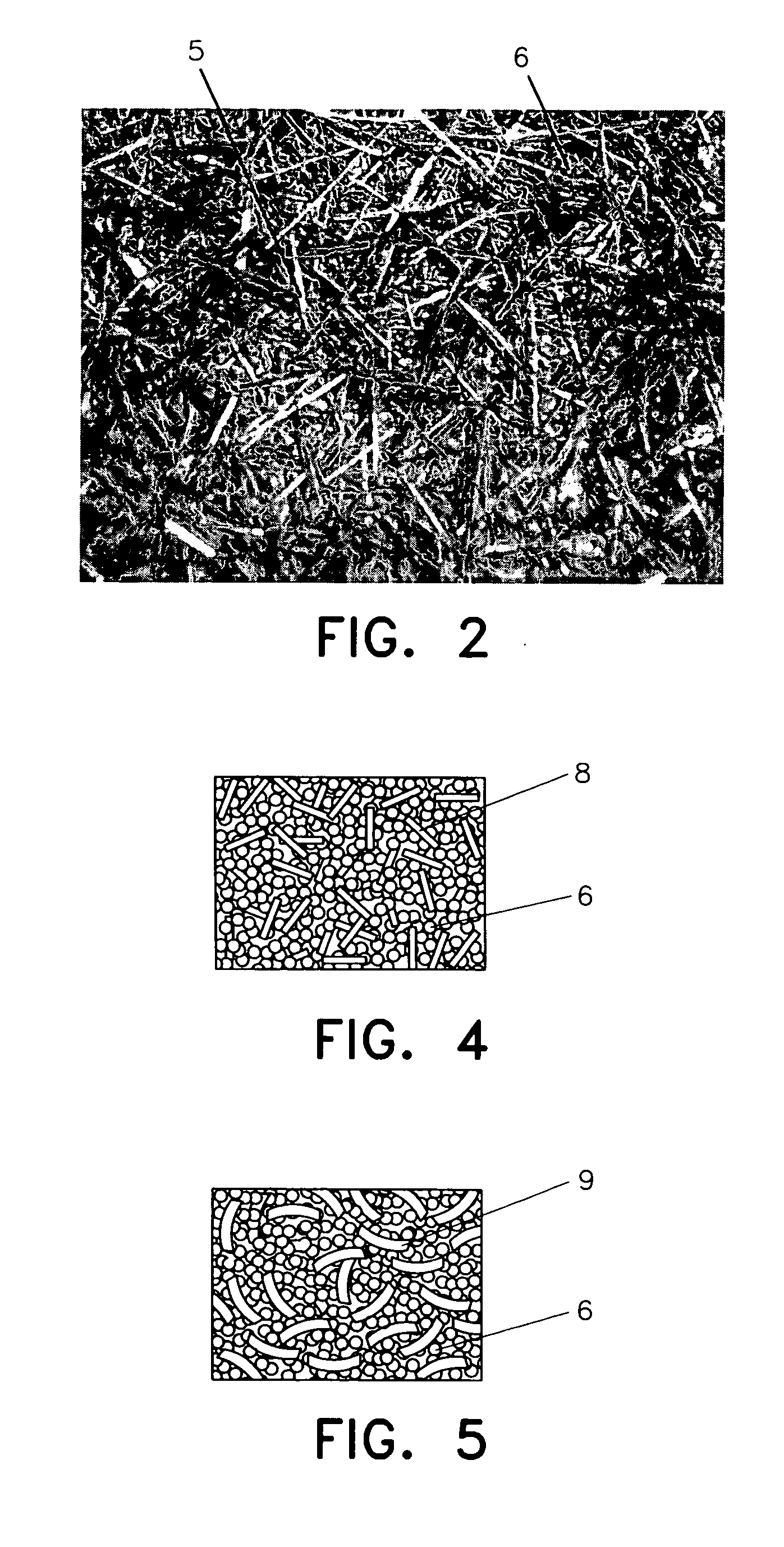

[0040] A hydrogen storage container consists of a container casing, a hydrogen storage mixture and a valve. The hydrogen storage mixture loaded into the container is made of hydrogen storage alloy granules and non-hydrogen-absorbing aluminum fibers. Hydrogen storage alloy MmNi4.5Mn0.5 used in this example belongs to the rare-earth based hydrogen storage alloys; Mm stands for the cerium-rich mischmetal. The ingots of MmNi4.5Mn0.5 should be crushed into small granules with a diameter of about 3 mm before being loaded into the container. The average length of the aluminum fibers is about 3 mm and average cross section is about 0.5 square millimeters. The total weight of aluminum fibers is about one percent of the total weight of hydrogen storage alloy granules. The bulk specific weight of the mixture is 3.6 g·cm−3. The operation of the hydrogen storage container is as follows. At first, the pressure in the container is adjusted to 133 Pa. Then, hydrogen of 99.99% purity is filled into ...

example 2

[0042] The hydrogen storage alloy for the granules in the mixture is the titanium-based alloy TiFe0.85Mn0.15. The non-hydrogen-absorbing alloy fibers are made of brass, with an average length of 11 mm and average cross section 1.2 mm2. The weight ratio of brass fibers to hydrogen storage alloy granules is about 0.05. The bulk specific weight of the mixture is 3.0 g·cm−3. The process of activation and initial charging is similar to those of Example 1. The test results show that the hydrogen storage capacity is 1.7%. Neither damage nor deformation of the container have been detected after 1000 hydriding / dehydriding cycles.

example 3

[0043] Magnesium based alloy Mg2Ni is used for the hydrogen storage alloy in the mixture of this example. The non-hydrogen-absorbing alloy for making alloy fibers is nickel alloy. The average length of the nickel alloy fibers is 20 mm, and their average cross sectional area is 2 mm2. The weight ratio of the nickel alloy fibers to the hydrogen storage magnesium based alloy is about 0.1. The size of hydrogen storage alloy granules initially loaded into the containers should be under 5 mm in diameter. The bulk density of the mixture is 2.2 g·cm−3. In this example, pre-heating of the container is necessary for hydrogen absorbing and desorbing. The container is heated to 300° C. and the pressure is adjusted to 50 Pa before the initial charging of hydrogen. Then, the container is charged with hydrogen of 99.99% purity at a pressure of 3.0 MPa. Then, the activation and hydriding of Mg2Ni can be started. During hydriding, Mg2Ni transforms to Mg2NiH4. The test results show that the hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com