Method of producing a microfluidic device

a microfluidic device and microfluidic technology, applied in the field of miniature instruments, can solve problems such as partial melting of substrate materials along the applied pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0031] An ice crystal (2×2×2 cm) was illuminated with a 40 W CO2 laser for 5 minutes. At the end of illumination it was found that a cylindrical hole of diameter 3 mm had been drilled through the crystal.

example 2a

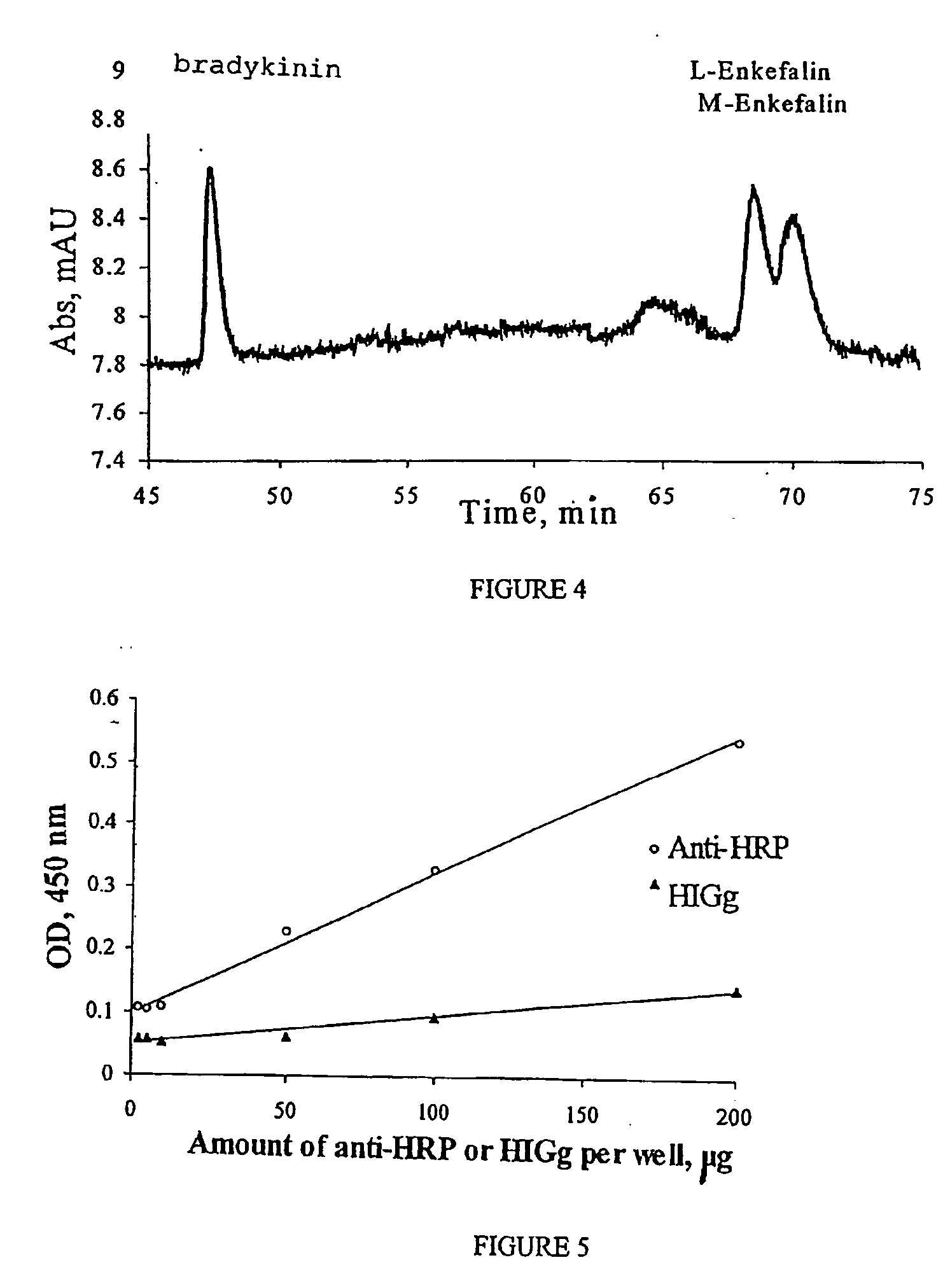

[0032] A 60 cm glass capillary (75 μm internal diameter) was filled with 10 mM HCl and frozen at −20° C. The capillary was mounted in a Waters 4000 E capillary electrophoresis instrument supplied with a thermostat. The applied potential was 10000 V and the temperature was maintained at −20° C. After I hour an internal part of the ice in capillary had been melted due to the applied potential, and the current passing through the system increased to 0.2 μA, after which it stabilised. A solution containing 1 mg / ml of each of bradykinin, L-enkefalin and M-enkefalin was injected into the capillary by hydrostatic pressure. The electropherogram which shows the achieved separation on ice-filled capillary is presented in FIG. 4.

example 2b

[0033] A 60 cm glass capillary (75 μm internal diameter) was filled with 10 mM HCl and frozen at −20° C. The capillary was mounted in Waters 4000 E capillary electrophoresis instrument supplied with thermostat. The applied potential was 10000 V and the temperature was maintained at −5° C. The current passing through the system stabilised at 1.5 μA which is an indication that ice has not been formed in the capillary. A mixture of bradykinin, L-enkefalin and M-enkefalin was injected into the capillary as in Example 2a. No separation was observed in this case due to absence of ice in capillary.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| internal diameter | aaaaa | aaaaa |

| internal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com