Method for generating plasma method for cleaning and method for treating substrate

a plasma generator and plasma technology, applied in the direction of cleaning processes and apparatus, chemistry apparatus and processes, electric discharge tubes, etc., can solve the problem of serious decrease in the throughput of semiconductor production, achieve significant improvement of the throughput avoid large voltage overshoot, and improve the effect of cleaning or substrate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0145] Hereinafter, explanation of the present invention will be made with regard to preferred embodiments.

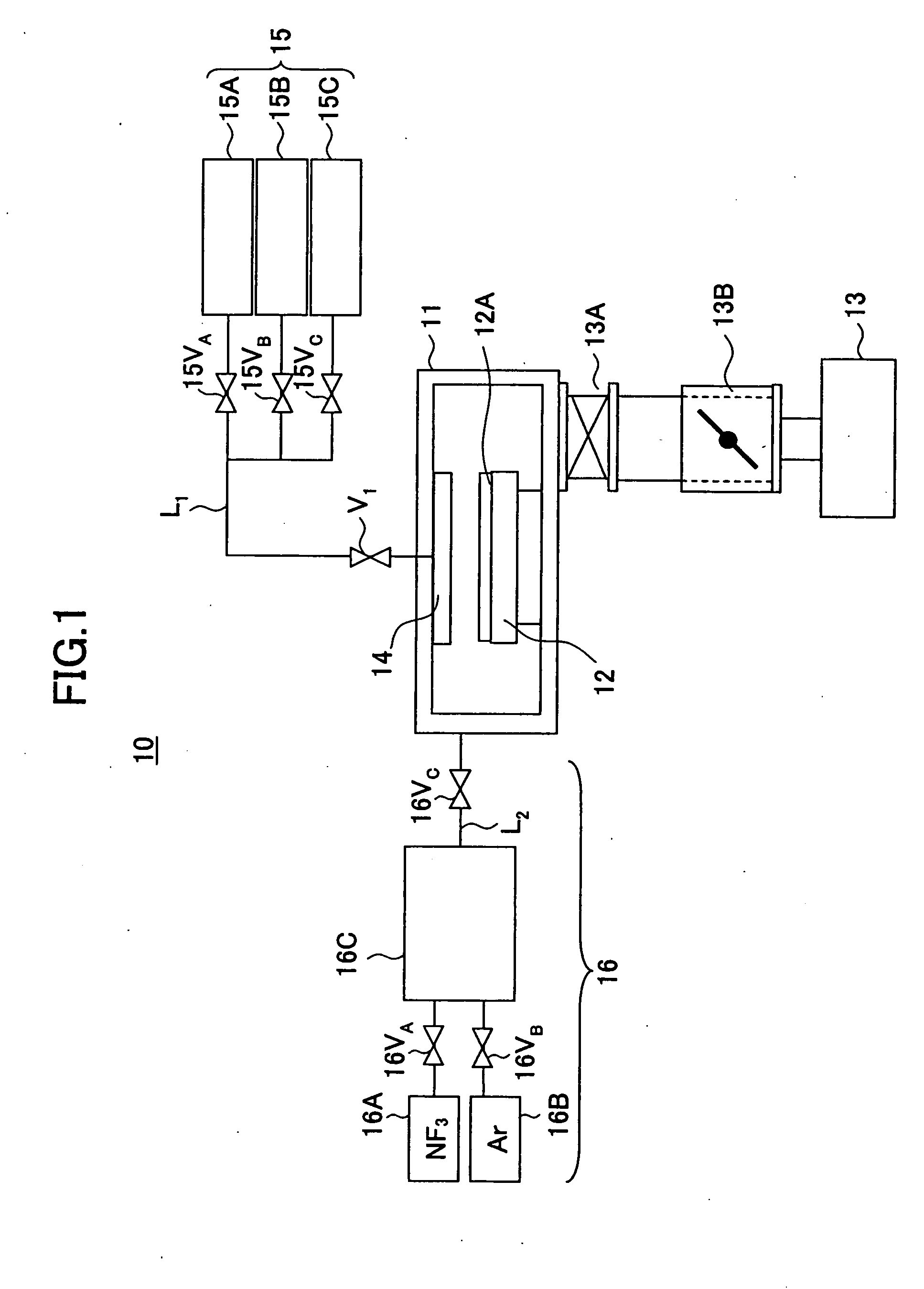

[0146] As explained previously, a toroidal plasma generator has an advantageous feature of reduced contamination in the substrate processing that uses plasma because of suppressed sputtering at the wall surface of the plasma generator, while there is a drawback in that plasma ignition is difficult. Thus there has been a need, when to carry out plasma ignition, of eliminating the etching gas or cleaning gas containing halogen having a large electronegativity such as NF3 and conduct the plasma ignition in an ambient of Ar gas 100%.

[0147] Thus, it has been recognized commonly that, with toroidal plasma generator, plasma ignition is possible only in the ambient of 100% Ar gas. Contrary to this, it came to the attention of the inventor of the present invention that average mean path length of electrons is increased under low pressure environment and predicted that electrons would ...

second embodiment

[0160]FIG. 12 shows the result of search for the plasma ignition condition for the case a mixed gas of Ar and F2 is supplied to the toroidal plasma generator 60 of FIG. 4 under various F2 concentrations (F2 / (Ar+F2)) according to the procedure similar to that of FIG. 9, as a second embodiment of the present invention.

[0161] In the experiment of FIG. 12, it should be noted that the flow rate of the Ar / F2 mixed gas is set to 100SCCM and the high-frequency power of 400 kHz frequency is supplied with the power of 1300 W.

[0162] Referring to FIG. 12, it can be seen that, in the case the total gas flow rate is set to 100SCCM and the F2 concentration in the mixed gas is 5%, plasma ignition takes place in the pressure range of approximately 6.65 Pa (0.05 Torr) or more but not exceeding approximately 66.5 Pa (0.5 Torr), and that this pressure range enabling plasma ignition decreases with increasing F2 concentration in the mixed gas. Still, plasma ignition is possible up to the F2 concentrati...

third embodiment

[0163] Thus, the inventor of the present invention has discovered, with the investigation that constitutes the foundation of the present invention, that plasma ignition is still possible with a toroidal plasma generator such as the one shown in FIG. 4, even in the case a mixed gas in which a gas containing halogen of large electronegativity such as NF3 or F2 is added to an Ar gas, is supplied to the plasma generator. Further, the inventor of the present invention has succeeded in finding out the condition enabling the plasma ignition.

[0164] On the other hand, the pressure or gas flow rate used in actual CVD apparatuses such as the CVD apparatus 10 of FIG. 1 for the cleaning process or etching process is much larger than the ignition point shown in FIG. 9 or 10, and thus, the toroidal plasma generator 60 is required to change the process condition, after the plasma ignition at the ignition point of FIG. 9 or 10, to the process point where the actual process is conducted, without ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com