Phosphorescent oled with mixed electron transport materials

a technology of electron transport materials and phosphorescent oled, which is applied in the direction of discharge tube luminescnet screens, natural mineral layered products, etc., can solve the problems of large loss of efficiency, large excitons, and performance limitations of oled devices, and achieve the effect of reducing the drive voltage of oled devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Compound A-16

[0312]

[0313] Compound (3), eq. 1, was prepared in the following manner. Under a nitrogen atmosphere, acetylenic compound (2) (2.0 g, 12 mMole), was dissolved in dimethylformamide (DMF) (100 mL) and the solution cool to 0° C. Potassium t-butoxide (KButO) (1.4 g, 12 mMole), was added and the mixture stirred well for approximately 15 minutes. To this mixture was then added the benzophenone (1) (3.53 g, 30 mMole). Stirring was continued at 0° C. for approximately 30 minutes and then allowed to come to room temperature over a 1-hour period. At the end of this time the solution was cooled to 0° C. and the reaction treated with saturated sodium chloride (20 mL). The mixture was then diluted with ethyl acetate, washed with 2N-HCl (3 times), dried over MgSO4, filtered and concentrated under reduced pressure. The crude product was triturated with petroleum ether to give the product as an off-white solid. The yield of compound (3) was 3.0 g.

[0314] Compound (3) (7.0 ...

example 2

Determination of LUMO Values

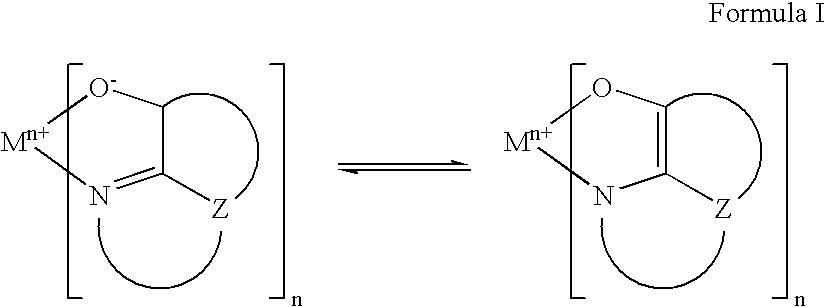

[0315] An important relationship exists when selecting the first compound and second compound(s) of the invention. A comparison of the LUMO values of the first and second compounds in the layer of the invention must be carefully considered. To obtain a drive voltage reduction over devices that contain only a first compound or only a second compound, there must be a difference in the LUMO values of the compounds. The first compound must have a lower LUMO (more negative) value than the second compound, or compounds.

[0316] The LUMO values are typically determined experimentally by electrochemical methods. A Model CH1660 electrochemical analyzer (CH Instruments, Inc., Austin, Tex.) was employed to carry out the electrochemical measurements. Cyclic voltammetry (CV) and Osteryoung square-wave voltammetry (SWV) were used to characterize the redox properties of the compounds of interest. A glassy carbon (GC) disk electrode (A=0.071 cm2) was used as working elec...

example 3

Determination of Low-Voltage Electron Transport Materials

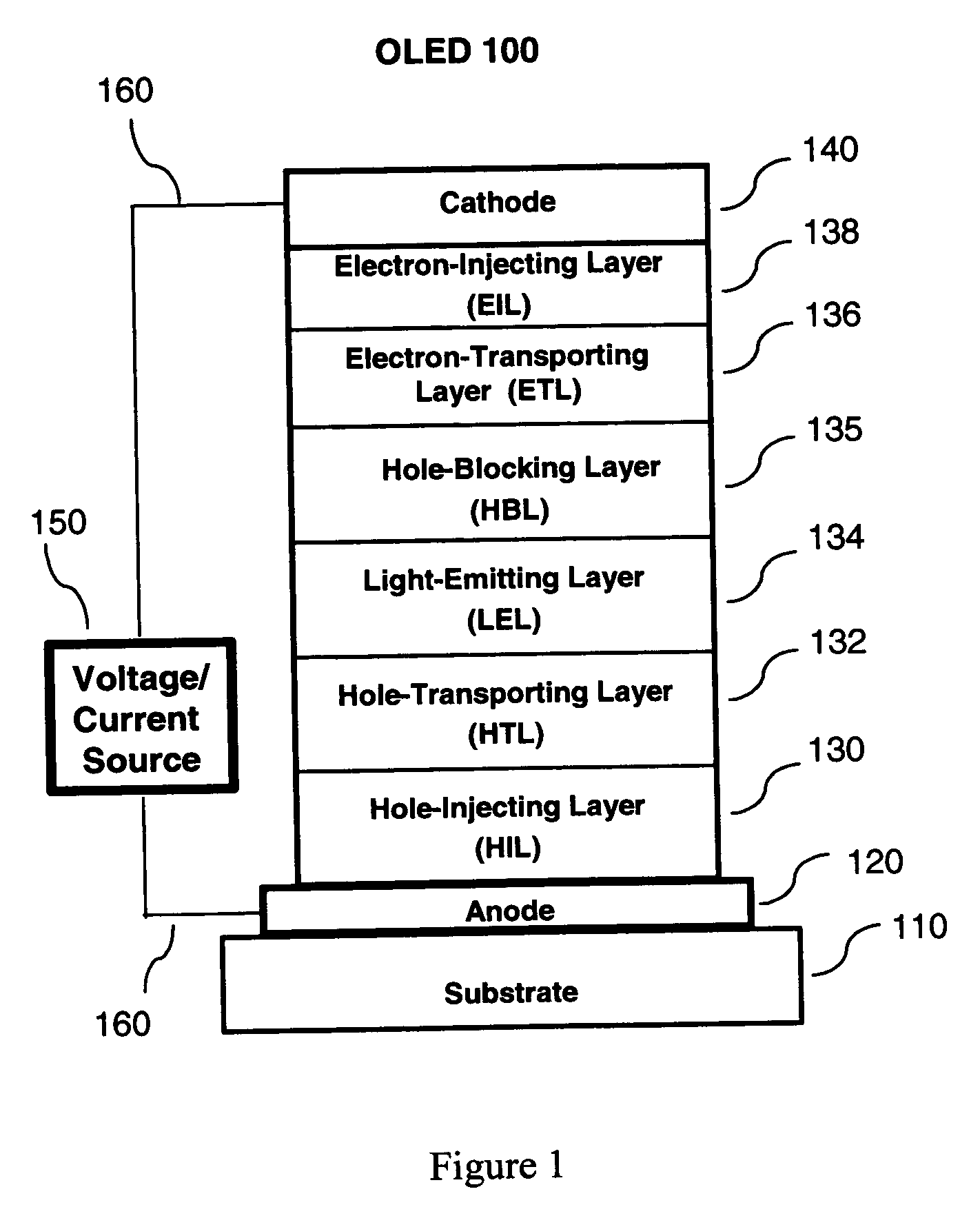

[0318] Materials were tested to determine if they were low voltage electron transport materials by incorporating them alone into the electron-transporting layer of a device. Devices were constructed in the following manner.

[0319] A glass substrate coated with an 85 nm layer of indium-tin oxide (ITO) as the anode was sequentially ultrasonicated in a commercial detergent, rinsed in deionized water, degreased in toluene vapor and exposed to oxygen plasma for about 1 min.

[0320] a) Over the ITO was deposited a 1 nm fluorocarbon (CFx) hole-injecting layer (HIL) by plasma-assisted deposition of CHF3.

[0321] b) A hole-transporting layer (HTL) of N,N′-di-1-naphthalenyl-N,N′-diphenyl-4,4′-diaminobiphenyl (NPB) having a thickness of 75 nm was then evaporated onto a).

[0322] c) A 35 nm light-emitting layer (LEL) of tris(8-quinolinolato)aluminum (III) (Alq) was then deposited onto the hole-transporting layer.

[0323] d) A 35 nm electron-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com