Photoresist stripping solution and a method of stripping photoresists using the same

a technology of photoresist and stripping solution, which is applied in the field of photoresist stripping solution and a method of stripping photoresist, can solve the problems of insufficient stripping for cu-based metallic deposition (residues) and insufficient stripping for cu-based metallic deposition (residues) and achieve the effect of efficient stripping and effective protection of al

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0075] The following examples are provided for the purpose of further illustrating the present invention but are in no way to be taken as limiting. Unless otherwise noted, all compounding amounts are expressed by mass percent.

[Treatment I]

[0076] A silicon wafer having an SiO2 layer formed thereon was used as a substrate. On this substrate, a TiN layer, an Al—Si—Cu layer and another TiN layer were successively formed thereon respectively as the first, second and third layers. The topmost layer was spin-coated with a positive-working photoresist (TDUR-P015 of Tokyo Ohka Kogyo Co., Ltd.), which was prebaked at 80° C. for 90 seconds to form a photoresist layer 0.7 μm thick.

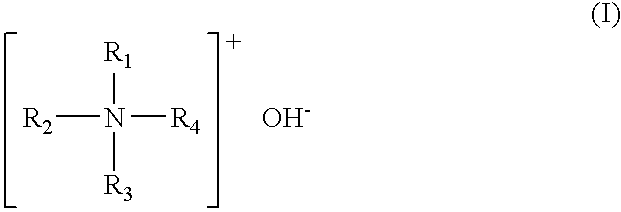

[0077] The photoresist layer was exposed through a mask pattern using FPA 3000 EX3 (Canon Inc.), then subjected to post-exposure bake at 110° C. for 90 seconds and developed with an aqueous solution of 2.38 mass percent tetraammonium hydroxide (TMAH) to form a photoresist pattern of 400 nm in line-and-space. Subseq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water-soluble | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com