Slow-release fertilizer and method of making and using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] A liquid slow-release nitrogen fertilizer in accordance with the present invention is prepared as follows.

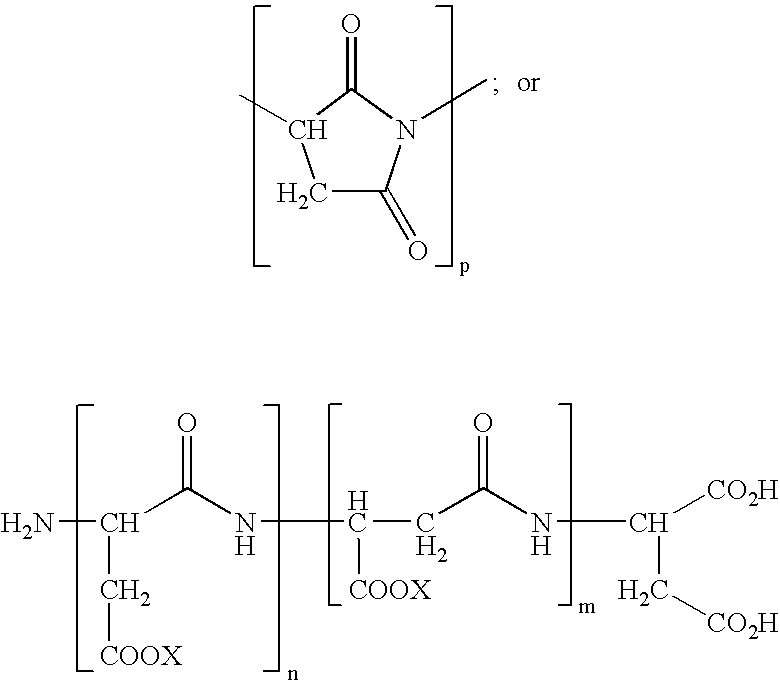

[0056] 50 gallons of LiquiGreen® are added to a mixing tank. LiquiGreen® is a liquid urea formaldehyde fertilize that contains up to 32 percent nitrogen, up to 80 percent of which is water-insoluble, which is commercially available from Regal Chemical Company, Inc., Alpharetta, Ga. To the LiquiGreen® is added 6 quarts of sodium polyaspartate having a weight average molecular weight of 1,000 to 10,000. The desired mixture of various molecular weights is then blended at ambient temperature with a paddle blender, bypass agitation or an air system. The resulting blend is useful as a liquid slow-release reacted nitrogen fertilizer.

example 2

[0057] A solid slow-release nitrogen fertilizer in accordance with the present invention is prepared as follows.

[0058] 100 pounds of solid urea formaldehyde are added to the hopper of a tumbling blender. 2-4 quarts of poly(amino acids) or salts thereof, such as, sodium polyaspartate are also added to the blender. The sodium polyaspartate is of one or more molecular weights of up to 10,000. The mixture is blended until the sodium polyaspartate is evenly distributed on the urea formaldehyde granules. The resulting blend is useful as a solid slow-release reacted nitrogen fertilizer.

example 3

[0059] A trial was conducted in a production field of “Savannah” mustard greens. The field was split using a standard nitrogen program of two applications of ammonium nitrate and a single pre-emergent application of Anchor™. Anchor™ is a mixture of 30% by weight liquid urea formaldehyde (66%-70% nitrogen of which 60%-70% by weight is water-insoluble) and 3% by weight sodium polyaspartate. All other fertilization was preformed in the same manner across the entire field. Tillage, planting and maintenance were done in accordance with normal production practices. Data was taken by harvesting paired samples from both the Anchor™ and the ammonium nitrate treated areas. The line between the two treatments was identified in the field. Samples were taken a few rows into the plots in order to avoid cross-contamination, but close enough that the paired samples were subjected to similar growing conditions. Applications were made using large-scale production equipment.

[0060] The treatments incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com