Activated Chemical Process for Enhancing Material Properties of Dielectric Films

a technology of activated chemical process and dielectric material, which is applied in the direction of fluid pressure measurement by mechanical elements, instruments, measurement devices, etc., can solve the problems of loss of dielectric propertites of layers, changes in chemical composition of dielectric materials, and damage to the mechanical strength of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

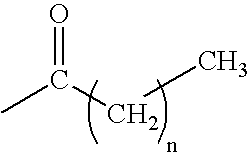

Method used

Image

Examples

example 1

[0063]A PDEMS™ 2.5 ATRP film (CVD dielectric film prepared from DEMS™ and porogen) was damaged in etch, ash, and wet clean processes to remove carbon from the film causing the dielectric constant of the film to rise from 2.57 (first dielectric constant) to 2.87 (second dielectric constant) (film thickness 2791 A, RI=1.385). The sample was taken into a first vacuum chamber at 400° C. and vacuum for 5 minutes. After cooling the wafer, the wafer was transferred to a second vacuum chamber at 45 C. The chamber was pressurized to 12 torr with diethoxymethylsilane (no carrier). The sample was allowed to equilibrate for 2-3 minutes with the chemical vapor to aid in the diffusion of the chemistry into the pore system. The wafer was then transferred to a third vacuum chamber at 300° C. equipped with a sweeping broad band UV source (Fusion I-600 Lamp with H+ bulb). The sample was exposed to the UV radiation for 1 minute. The sample was removed from the chamber. The dielect...

example 2

[0064]10 wt % solution of heptamethyidisilazane in 2-hexanone was mixed in a polypropylene bottle. A PDEMS™ 2.5 ATRP film (CVD dielectric film prepared from DEMS™ and porogen) was damaged in etch, ash, and wet clean processes to remove carbon from the film causing the dielectric constant of the film to rise from 2.53 (first dielectric constant) to 2.8 (second dielectric constant) (film thickness 3322 A, RI=1.338). A piece of this film was placed onto a spin coater. Approximately 3 mls of solution was placed on the film. The chemistry remained in contact with the film for 90 seconds before the restoration chemistry was removed via spin drying. The sample was moved to a vacuum chamber at 300 C equipped with a sweeping broad band UV source. The sample was exposed to 100% power UV light for 1 minute. After treatment the dielectric constant of the film was 2.46 (third dielectric constant) (film thickness 3215 A, RI=1.346). This example shows that the choice of che...

example 3

[0065]A PDEMS™ 2.5 ATRP film (CVD dielectric film prepared from DEMS™ and porogen) was damaged in etch, ash, and wet clean processes to remove carbon from the film causing the dielectric constant of the film to rise from 2.57 (first dielectric constant) to 2.87 (second dielectric constant) (film thickness 2791 A, RI=1.385). The sample was taken into a first vacuum chamber at 400° C. and vacuum for 5 minutes. After cooling the wafer, the wafer was transferred to a second vacuum chamber at 45° C. The chamber was pressurized to 15 torr with diethoxymethylsilane (no carrier). The sample was allowed to equilibrate for 2-3 minutes with the chemical vapor to aid in the diffusion of the chemistry into the pore system. The diethoxymethylsilane was pumped out of the chamber and a flow of 200 mg / min of diethoxymethylsilane was started. Once flow had stabilized, a plasma (75 watts) was struck for 10 seconds. At the completion of the plasma step the chamber was pumped down and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com