Biocompatible solid-phase microextraction coatings and methods for their preparation

a solid-phase microextraction and coating technology, applied in the direction of component separation, yarn, diagnostics, etc., can solve the problems of significant chance of sample preparation errors affecting the chemical balance inside the animal, time-consuming and labor-intensive, and inability to achieve the effect of reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

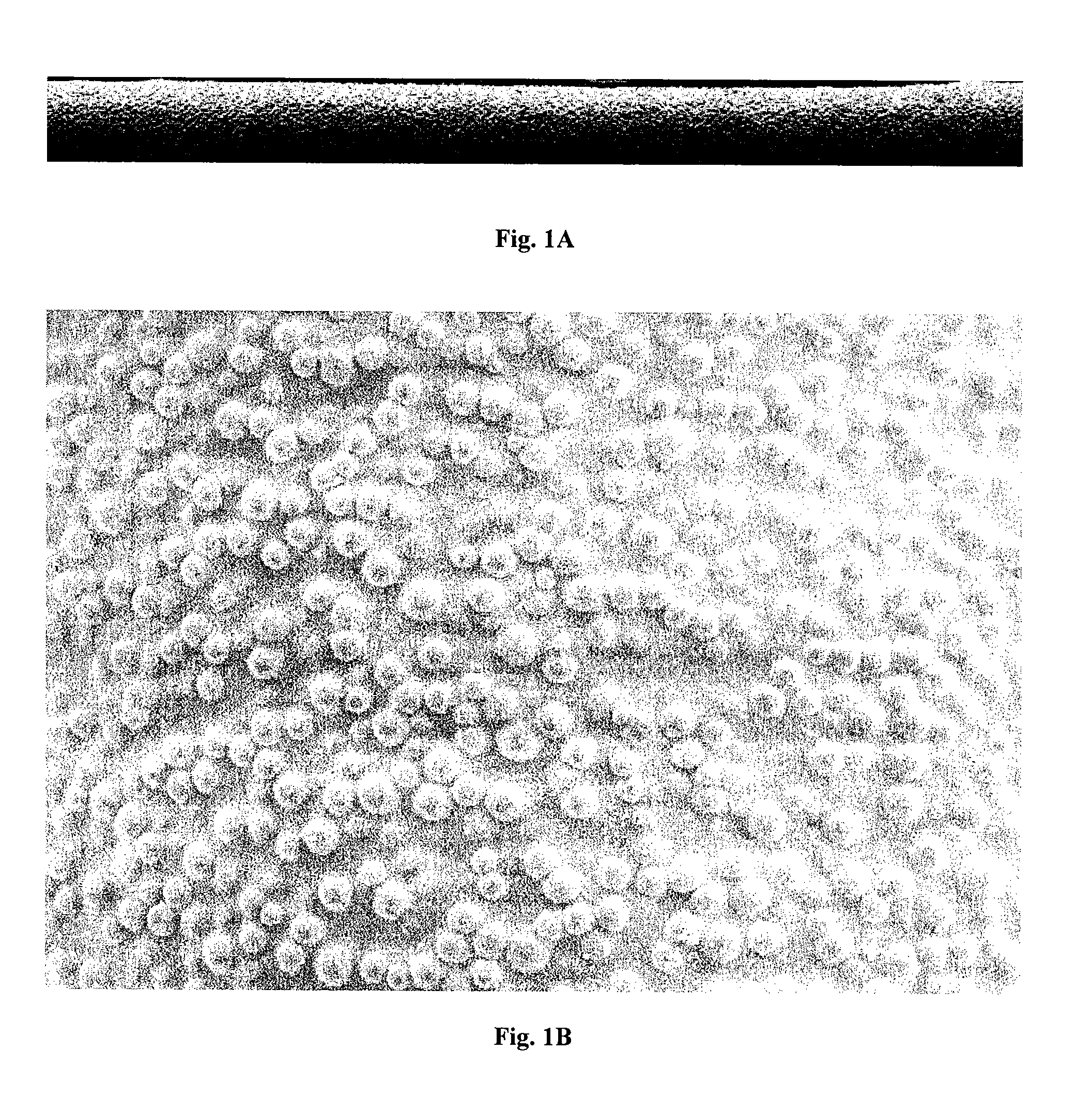

[0045]Particles commonly used as HPLC stationary phases (0.47 g of C-18, RP-amide, or HS-F5 particles) were brought into suspension with 2 g of a solution made up of 10% w / w PAN in DMF. SPME coatings with a length of 1.5 cm were prepared by applying a uniform layer of slurry of PAN and different particles on the surface of stainless steel wires, allowing to dry under flowing nitrogen, and finally curing for about 1.5 min at 180° C. The SPME coating was applied by dipping the wires into the slurry and removing them slowly.

example 2

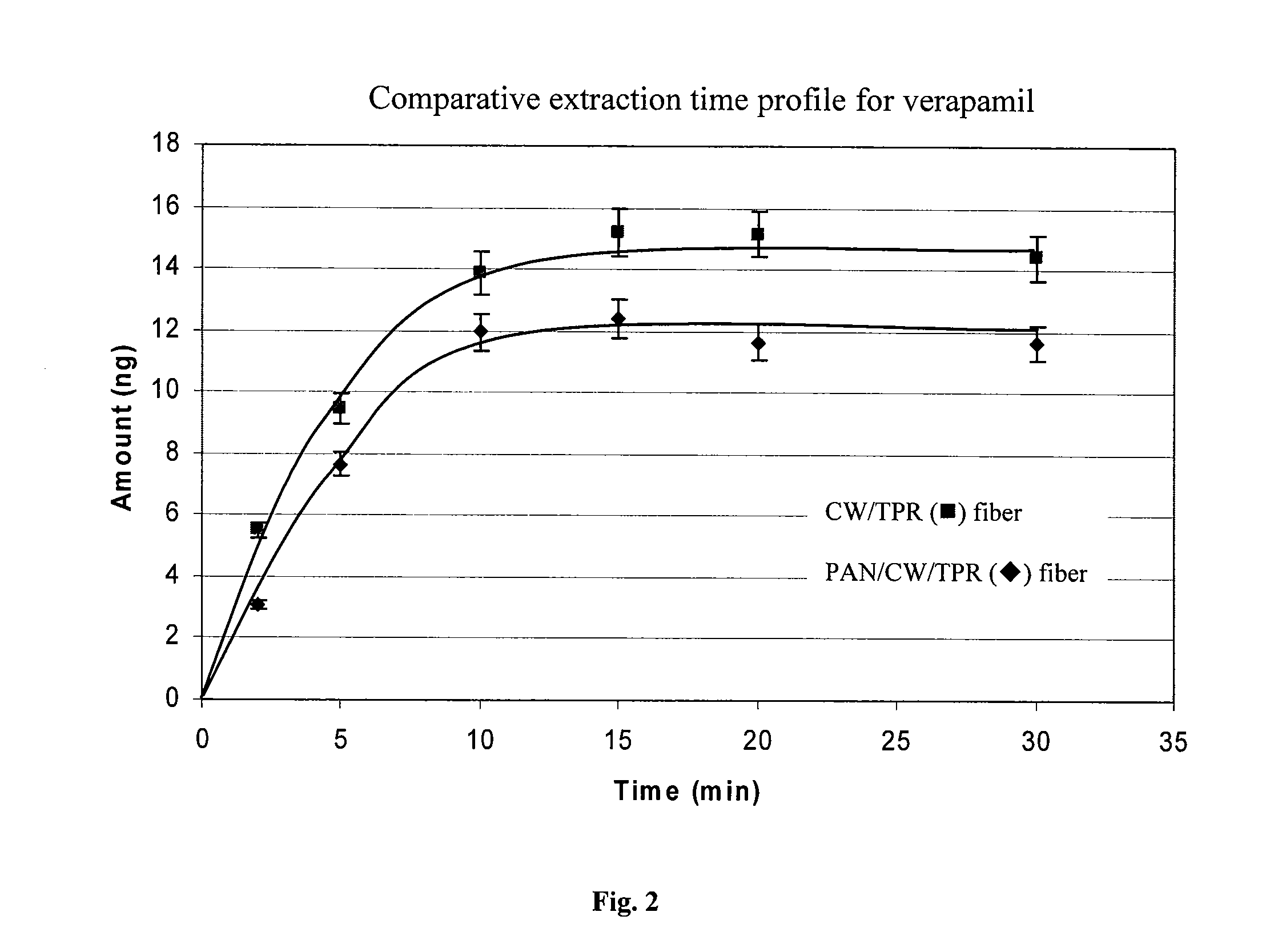

PAN as a Membrane

[0046]Existing fibers with conventional extraction phases (CW / TPR—carbowax / templated resin, from Supelco, PA) were coated with PAN by dipping them for 2 min in a solution of 10% PAN in DMF. Subsequently, the fibers were removed slowly from the solution, allowed to dry under flowing nitrogen, and finally cured by a short exposure (5 s) to a flow of nitrogen at 200° C.

example 3

Continuous Coating

[0047]Wire was coiled on a first reel and threaded through an applicator filled with a coating suspension. The wire was then threaded through a heater and attached to a take-up reel. The wire was drawn through the both the applicator and heater at a set speed. The thickness of the coating was measured and additional coatings were applied by switching the positions of the first reel and take-up reel, and repeating the previous coating, drying and switching steps until a desired thickness is achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular mass | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com