Composite phosphors based on coating porous substrates

a technology of porous substrates and composite phosphors, which is applied in the direction of luminescent compositions, transportation and packaging, chemistry apparatuses and processes, etc., can solve the problems of reducing quantum yield, reducing extraction efficiency, and reducing efficiency, so as to achieve enhanced light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

[0050]A hafnium coating solution was prepared by mixing 1.0 g of HfOCl2 (ALDRICH, 99.99% pure), 1.0 g K2EDTA (ALDRICH, 99.995% pure), and 1 grams BASF polyethyleneimine polymer in deionized (18 MΩ) H2O. The resulting solution was filtered through a 0.45 micron filter, diluted to 200 mL with nano pure water, and purified by Amicon filtration with a 3,000 MW cut-off filter. The final concentrated solution was 144 mM hafnium, determined by ICP / AES. The potassium concentration was 11 mM, also determined by ICP / AES.

example b

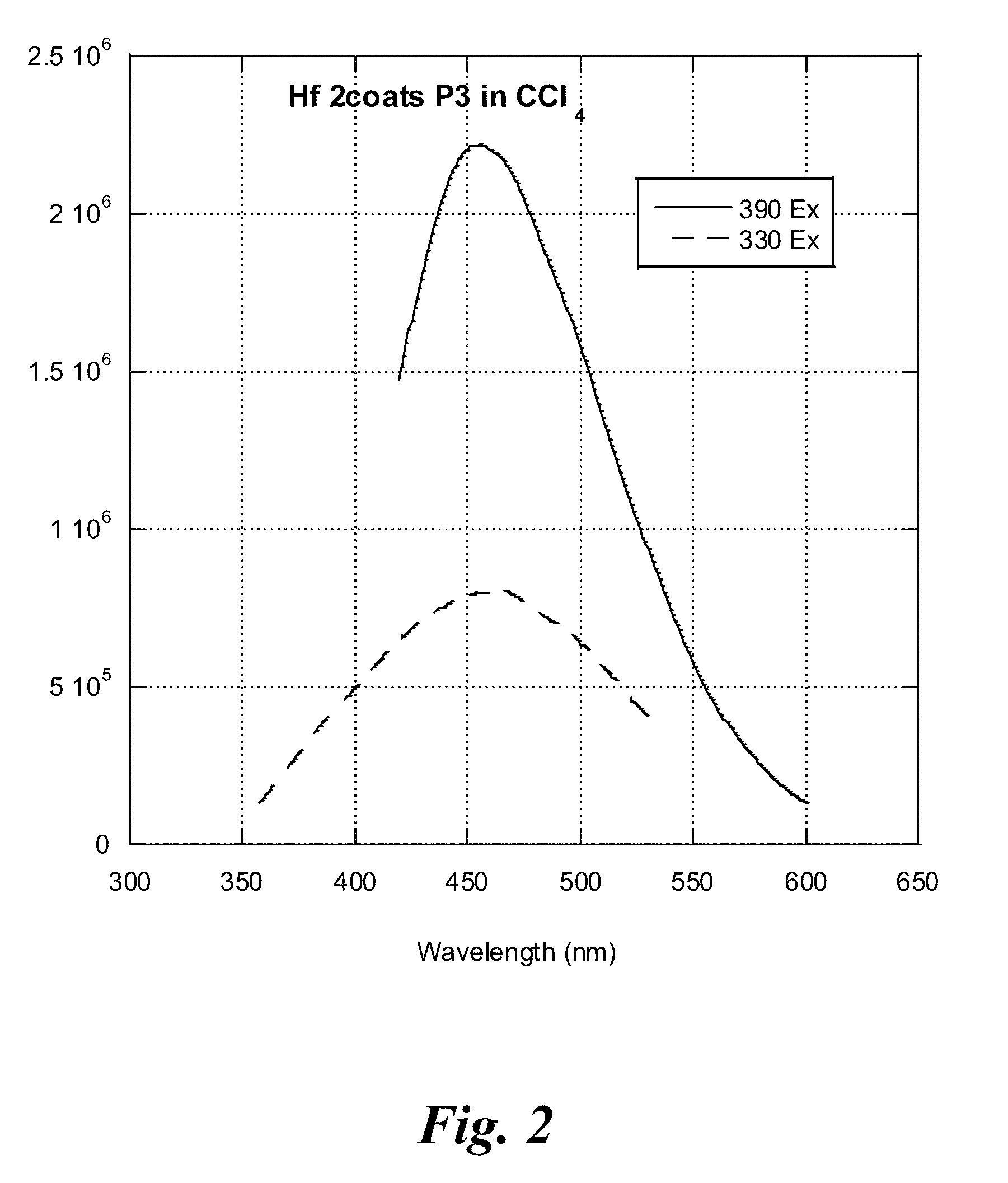

[0051]A hafnium coating solution was prepared by mixing 2.0 g of HfOCl2 (ALDRICH, 99.99% pure), 2.0 g HEDTA (ALDRICH, 99.995% pure) and 2 grams BASF polyethyleneimine polymer and concentrated ammonium hydroxide, NH4OH (Fisher) in deionized (18 MΩ) H2O. The resulting solution was filtered through a 0.45 micron filter, diluted to 200 mL with nano pure water, and purified by Amicon filtration with a 3,000 MW cut-off filter. The final concentrated solution was 163 mM hafnium, determined by ICP / AES. This solution was rotovapped to further concentrate it, resulting in a final concentration of 250 mM hafnium.

example c

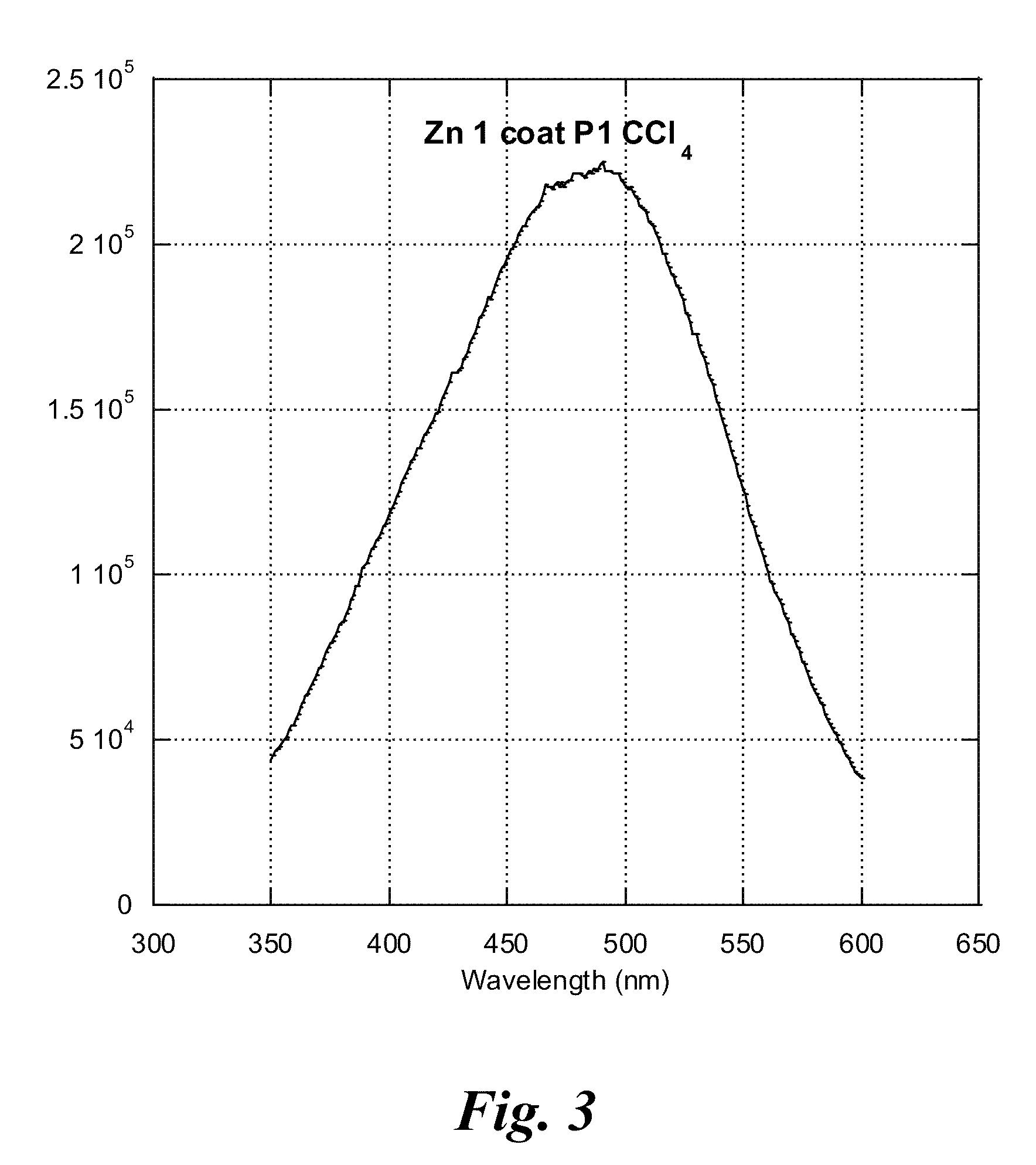

[0052]A zinc solution was prepared by mixing 3.7 g zinc nitrate hexahydrate, Zr(NO3)2 6H2O, (ALPHA AESAR, 99.998% pure), 5.0 g HEDTA (ALDRICH, 99.995% pure) and 5 grams BASF polyethyleneimine polymer in deionized (18 MΩ) H2O. The resulting solution was filtered through a 0.45 micron filter, diluted to 200 mL with nano pure water, and purified by Amicon filtration with a 3,000 MW cut-off filter. The final concentrated solution was 179 mM zinc, determined by ICP / AES.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| extraction efficiencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com