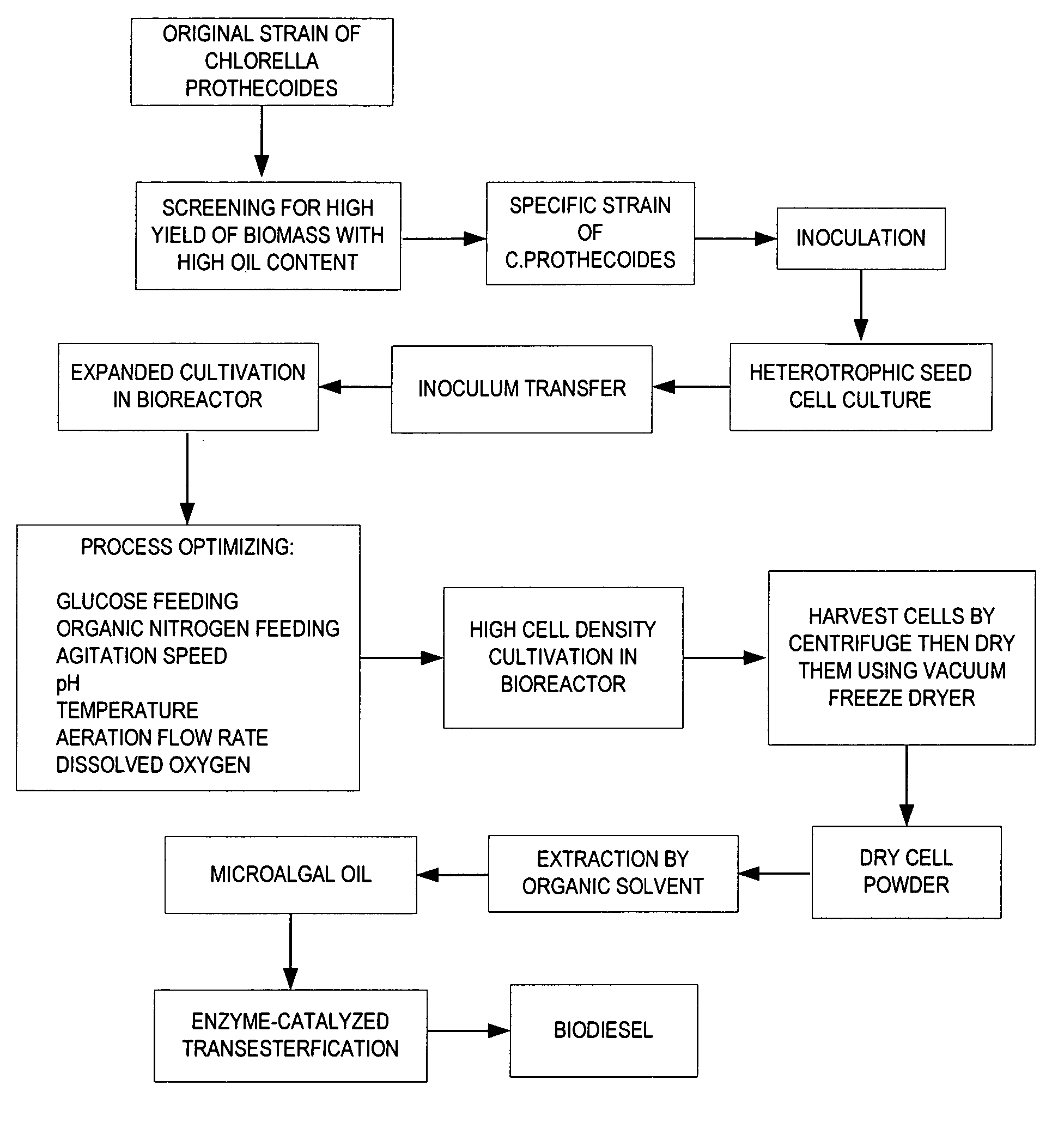

Method for producing biodiesel using high-cell-density cultivation of microalga Chlorella protothecoides in bioreactor

a bioreactor and microalga chlorella technology, applied in biofuels, biofeedstock, biofuels, etc., can solve the problems of high cost of biodiesel, inability of conventional oil/food crop-based biodiesel production system to meet the growing demand for sustainable feedstock for biodiesel production, and no biodiesel production technology by microalgae is economically feasible, etc., to achieve the effect of reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Materials and Methods

[0106]The original strain of C. protothecoides came from the Culture Collection of Alga at the University of Texas (Austin, Tex.), which has been kept in Department of Biological Science and Biotechnology in Tsinghua University since 1990. The compositions of the culture medium for this strain are:[0107]KH2PO4: 0.7 g / L,[0108]K2HPO4: 0.3 g / L,[0109]MgSO4.7H2O: 0.3 g / L,[0110]FeSO4.7H2O: 3 mg / L,[0111]Glycine: 0.1 g / L,[0112]vitamin B1: 0.01 mg / L,[0113]A5 trace mineral solution 1.0 ml / L.

[0114]By oriented selection and screening as described in step (1) above, the specific strain with characteristics of high cell growth rate and high oil content is obtained as Chlorella. Protothecoides sp 0710. Comparing with the original cells, the Chlorella. Protothecoides sp 0710 is in golden color, cell dry weight approximately 108 g / l with oil / lip content at about 61% of cell dry weight. Table 1 illustrates compositions of biodiesel produced by the Chlorella. Protothecoides sp 071...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com