Method and System for Hydrolytic Saccharification of a Cellulosic Biomass

a cellulosic biomass and hydrolysis technology, applied in the direction of oligosaccharides, glucose production, pressurized chemical processes, etc., can solve the problems of difficult to cool a large amount of supercritical or subcritical water in a short time, difficult to put this method into practice in view of the economic aspect, etc., to save the required calorie, high yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

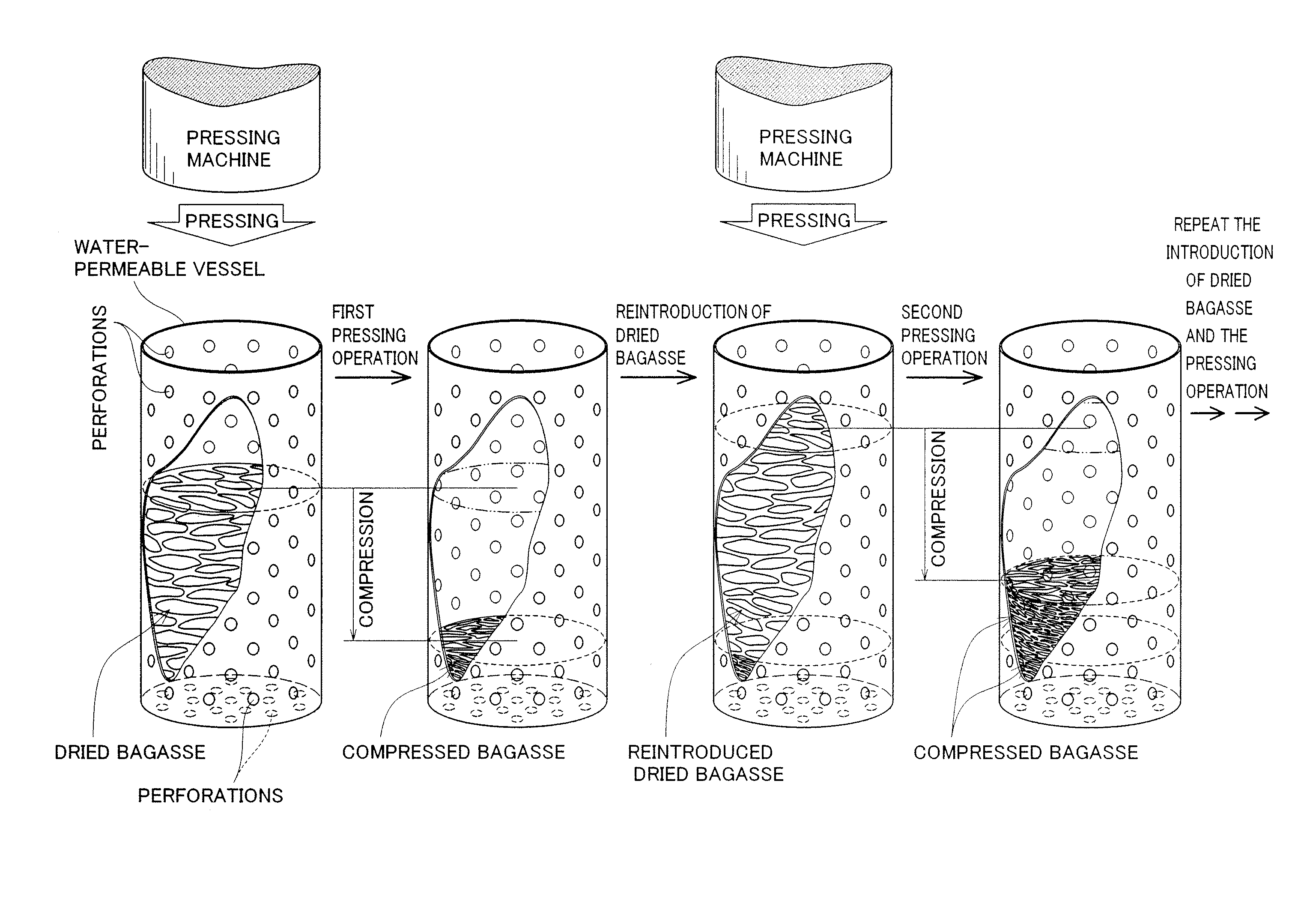

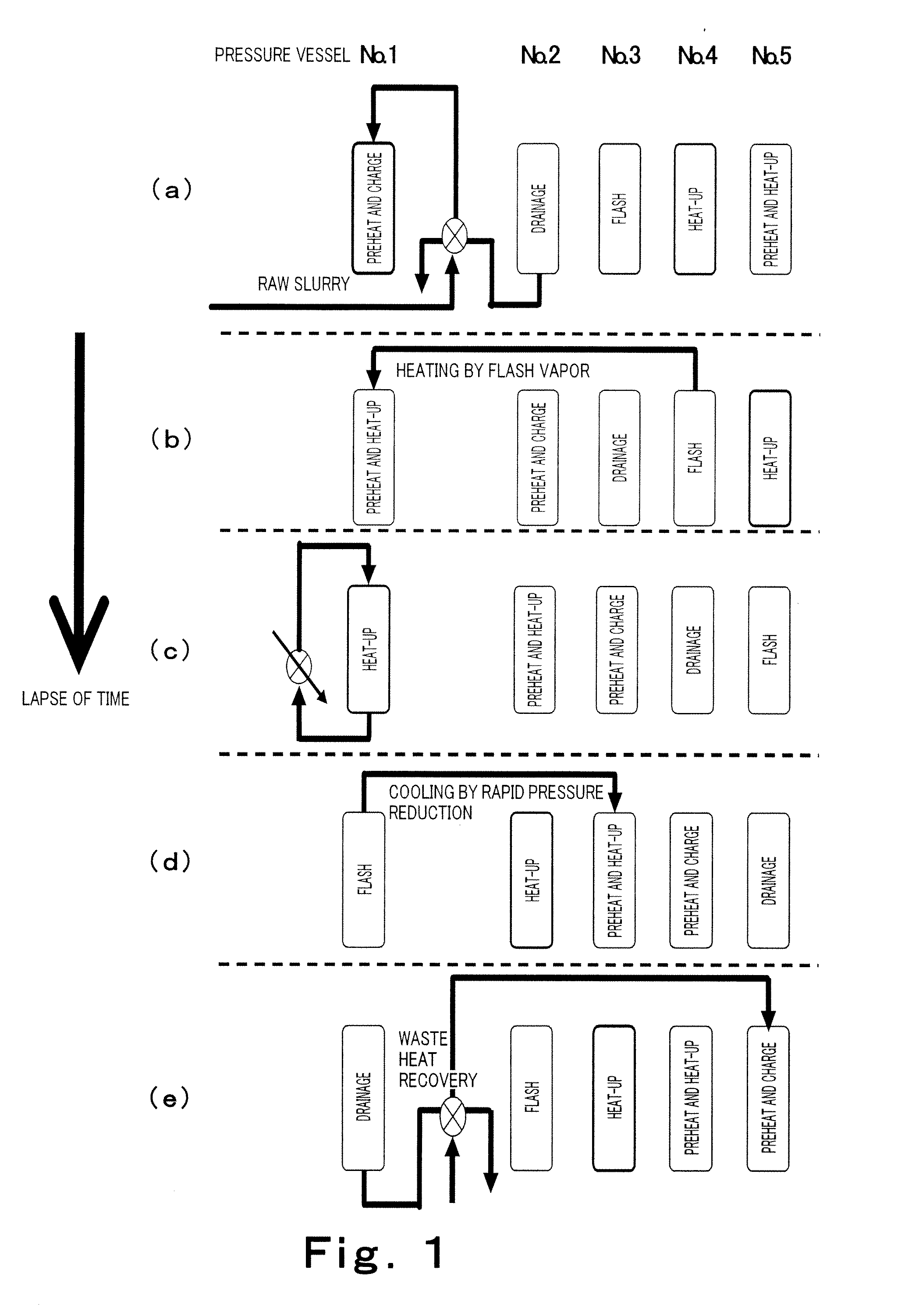

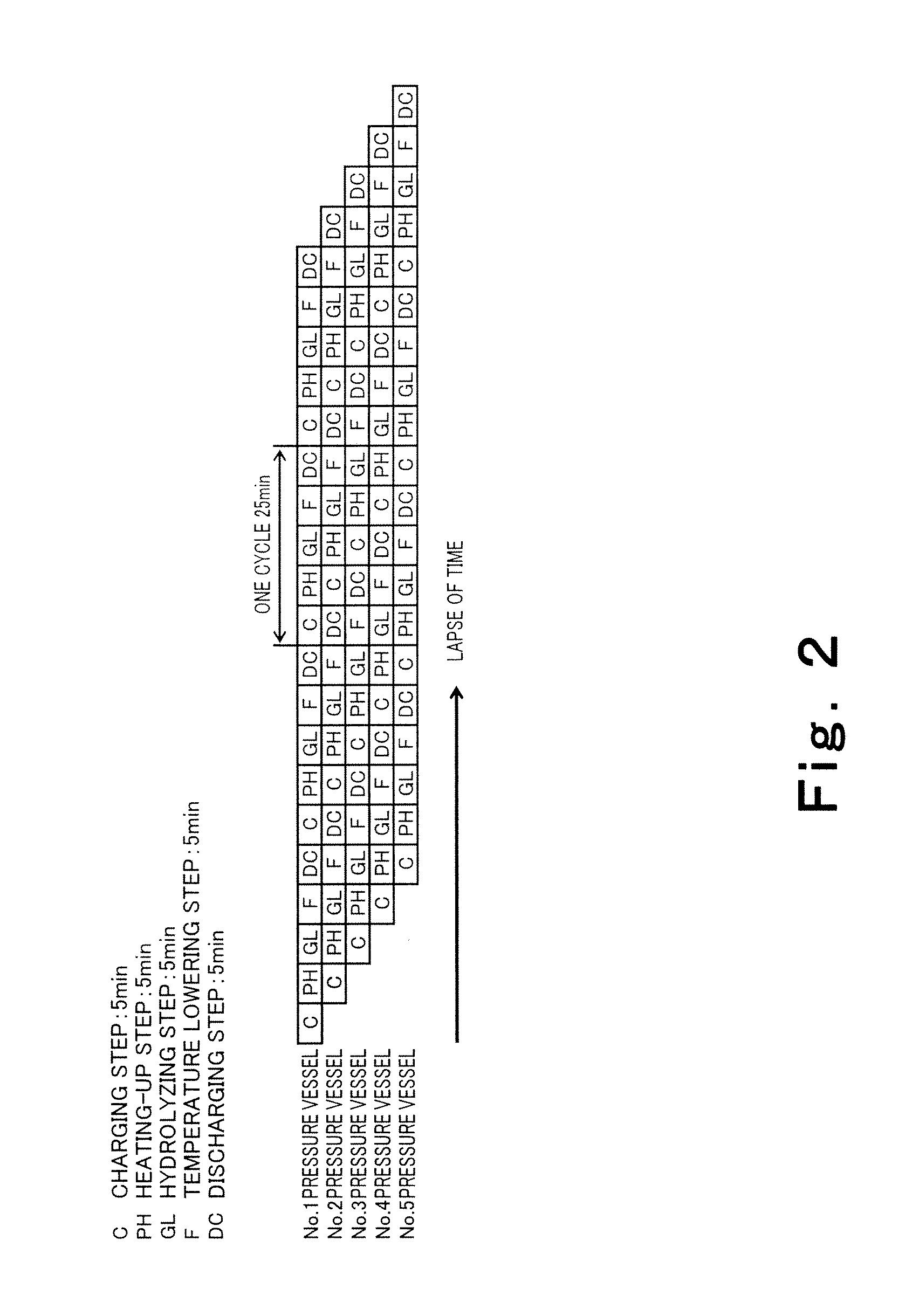

[0109]Referring to FIG. 1, description will be made of a procedure for operating a hydrolytic saccharification system configured to perform five process steps in total and use five pressure vessels according to embodiment 1.

[0110]First, a cellulosic biomass (for example, a vegetation biomass comprising bagasse, sugar beet residue, straws or the like) is ground to sizes of not more than several millimeters and then mixed with water or a dilute ethanol aqueous solution (2 to 10 mol %) to prepare a slurry having a solid matter concentration of about 30%. The slurry thus obtained (raw slurry) is charged into pressure vessel No. 1, as shown in FIG. 1(a) (charging step). Since there is no thermal energy released from any other pressure vessel at the time the hydrolytic saccharification system starts operating, the raw slurry cannot be preheated by heat exchange.

[0111]Pressure vessels Nos. 1 to 5 each repeatedly perform the sequence of process steps: charging step→heating-up step→hydrolyzi...

embodiment 2

[0129]Referring to FIG. 3, description will be made of a time schedule for operating a hydrolytic saccharification system as a sequencing batch system, the hydrolytic saccharification system being configured to perform four steps in total and use four pressure vessels each configured to perform the discharging step and the charging step in parallel as a discharging and charging step in a steady operation. In FIG. 3, the time required to complete each step is five minutes.

[0130]Initially, pressure vessel No. 1 performs the first charging step Co and, subsequently, pressure vessels Nos. 2 to 4 perform the first charging step Co sequentially with a time lag of five minutes from one pressure vessel to the next one. When the system starts operating, the system performs the same charging step as does the hydrolytic saccharification system shown in FIG. 1. For this reason, the discharging and charging step performed first is referred to as “first charging step Co” in FIG. 3. In steady oper...

embodiment 3

[0138]Referring to FIG. 5, description will be made of a time schedule for operating a hydrolytic saccharification system as a sequencing batch system, the hydrolytic saccharification system being configured to perform five steps in total and use eight pressure vessels. This system is adapted to cases where a cellulosic biomass is difficult to hydrolytically saccharificate under the subcritical condition and, hence, the hydrolyzing step cannot but be performed for a longer time than the other four steps. In FIG. 5, the time required to complete the hydrolyzing step is 20 minutes and that required to complete any other step is five minutes.

[0139]Initially, pressure vessel No. 1 performs the charging step and, subsequently, pressure vessels Nos. 2 to 8 perform the charging step sequentially with a time lag of five minutes from one pressure vessel to the next one. Each pressure vessel repeats the five sequential steps: [C]→[PH]→[GL]→[F]→[DC]. Here, the time required to complete the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com