Method for making a silicon quantum dot fluorescent lamp

a fluorescent lamp and quantum dot technology, applied in the manufacture of electric discharge tubes/lamps, cold cathode manufacturing, electromechanical systems, etc., can solve the problems of affecting throughput, hazard to the environment of mercury, complex structure, etc., and achieves efficient heat transfer and a lot of electrons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

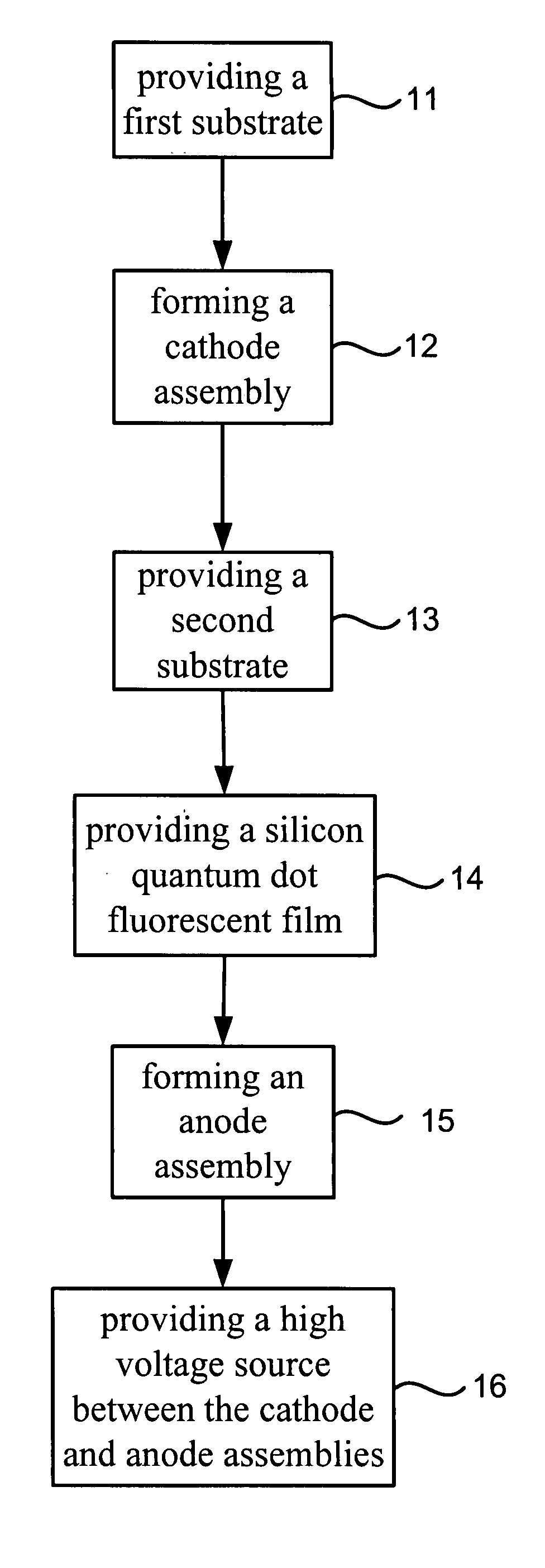

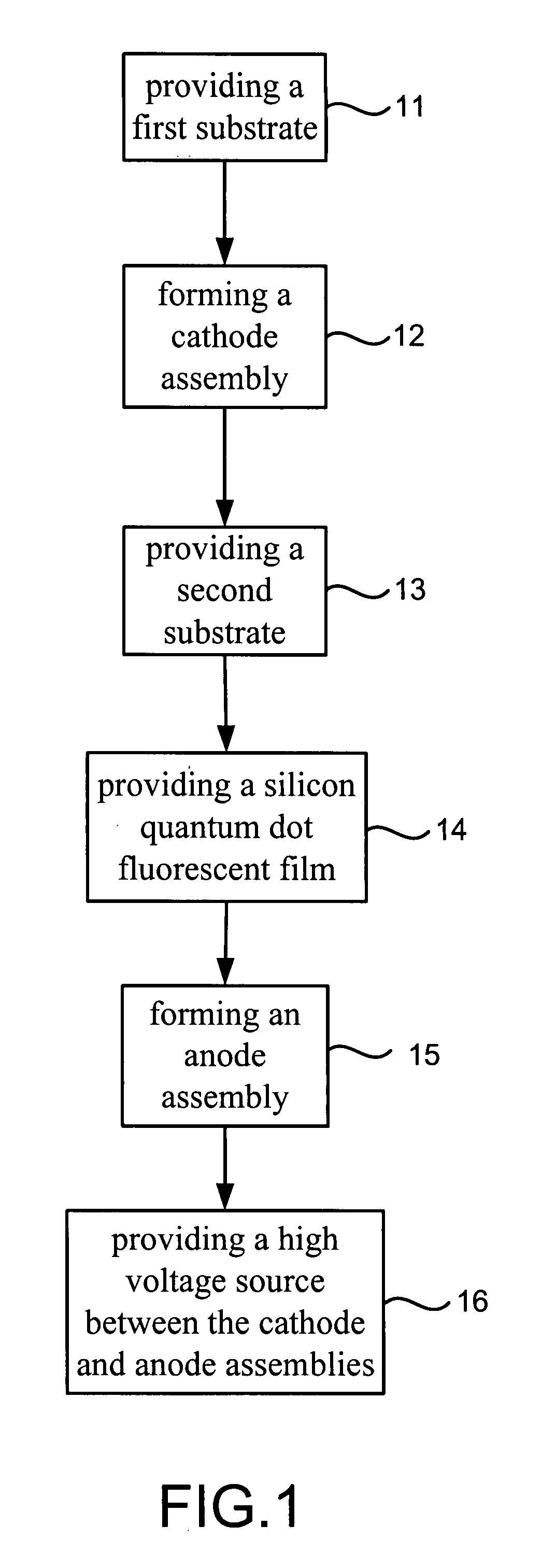

[0030]Referring to FIG. 1, there is shown a method for making a silicon quantum dot fluorescent lamp according to the preferred embodiment of the present invention.

[0031]Referring to FIGS. 1 and 2, at 11, a first substrate 21 is provided. The first substrate 21 may be made of silicon, glass, ceramic or stainless steel.

[0032]Referring to FIGS. 1, 3 and 4, at 12, the first substrate 21 is coated with a buffer layer 22, and the buffer layer 22 is coated with a catalytic layer 23. The coating is done in an e-gun evaporation system or a sputtering system. The buffer layer 22 is made of titanium. The catalytic layer 23 is made of nickel, aluminum or platinum. Referring to FIG. 3, nanometer carbon tubes 24 are provided on the catalytic layer 23 in a chemical vapor deposition (“CVD”) process in which ethane or methane is used as a carbon source. Referring to FIG. 4, instead of the nanometer carbon tubes 24, nanometer silicon wires 25 are provided on the catalystic layer 23 in a CVD process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com