Copper alloy sheet

a technology of copper alloy and copper alloy, applied in the field of copper alloy sheets, can solve the problems of achieving great cost reduction, and achieve the effect of reducing strength, excellent strength-ductility balance, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) Best Mode for Carrying Out First Embodiment of the Present Invention

[0083]The first embodiment of the present invention is described in detail below.

[0084](X-Ray Diffraction)

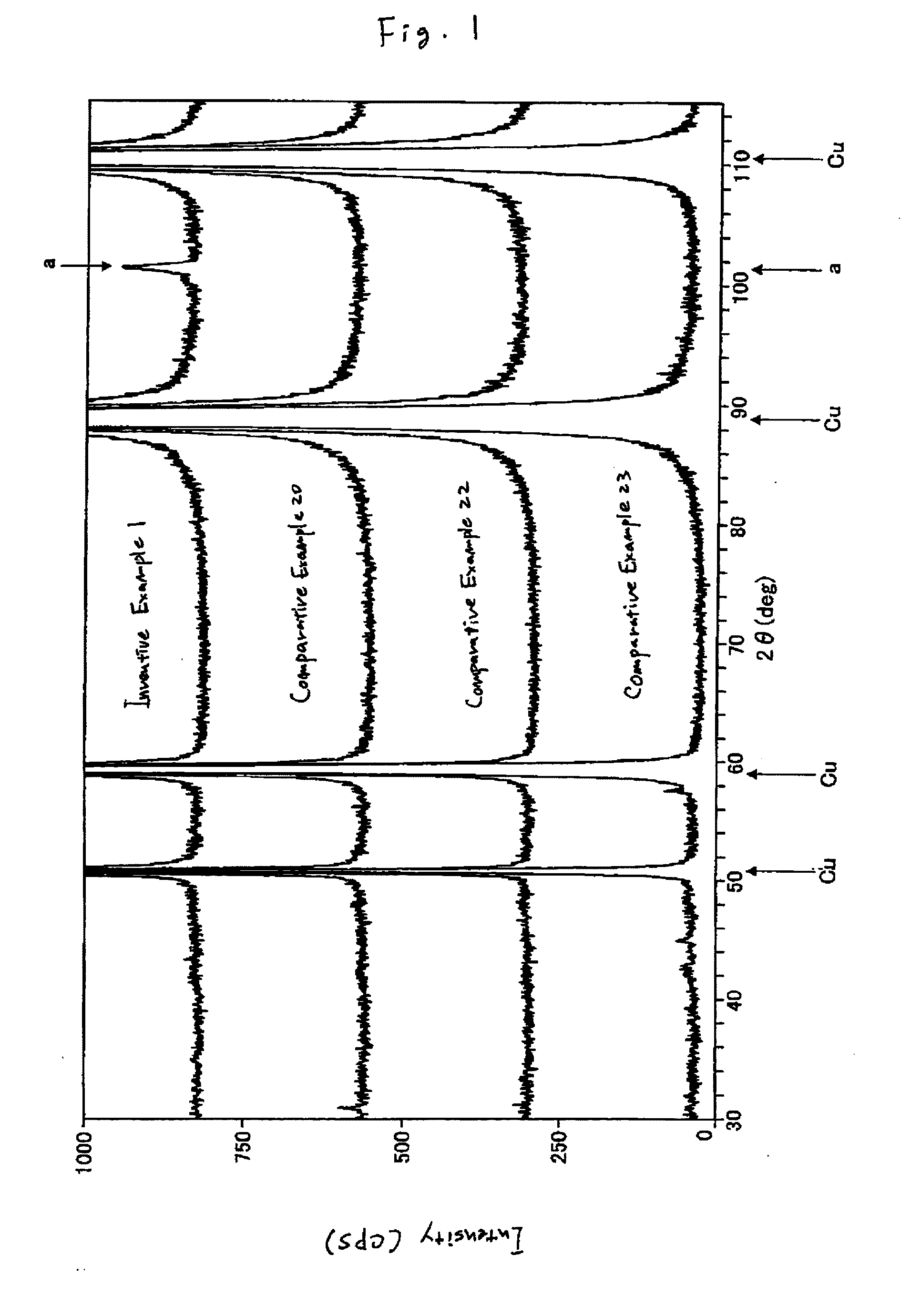

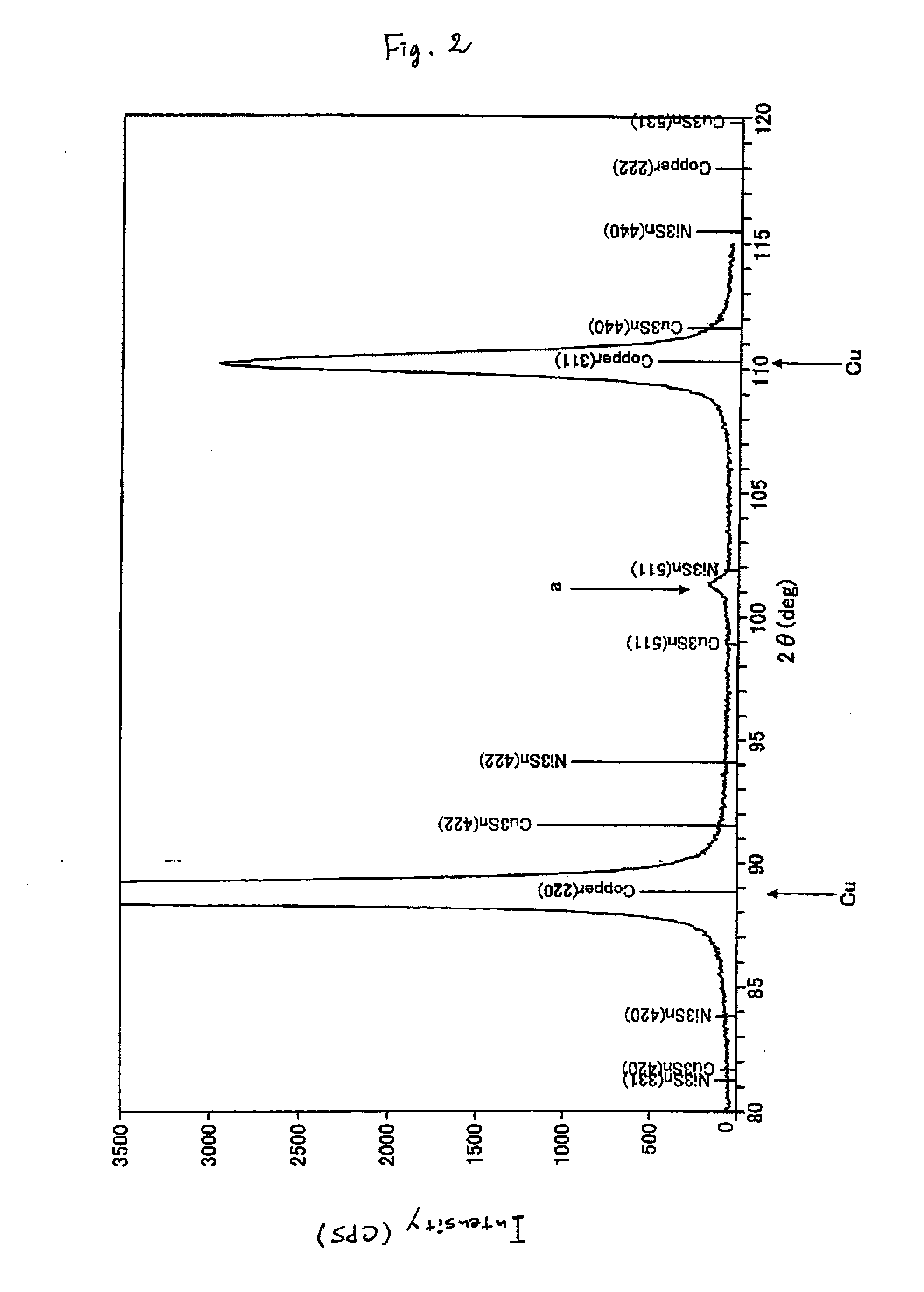

[0085]In the first embodiment of the present invention, a specific intensity peak in the X-ray diffraction pattern is specified as an important measure of novelty of a copper alloy sheet with excellent strength-ductility balance. That is, in the X-ray diffraction pattern of the copper alloy sheet, an intensity peak is specified to be present at the X-ray diffraction angle (2θ) between 100° and 102°.

[0086]This specific intensity peak is, as described later, presumed to be assignable to an Ni—Sn-based compound, but because of an alloy component or alloy element, the peak height is extremely low as compared with the intensity peak height of Cu which is originally main as the matrix. Whether the degree of this specific peak height contributes to the difference in the properties such as elongation of the Cu—Ni—Sn...

second embodiment

(2) Best Mode for Carrying Out Second Embodiment of the Present Invention

[0133]In the next place, the second embodiment of the present invention is described in detail below.

[0134](X-Ray Diffraction Intensity Ratio)

[0135]The X-ray diffraction intensity ratio in the second embodiment of the present invention is determined as follows. The X-ray diffraction intensity I(200) from (200) plane as the Cube orientation in the sheet surface and the X-ray diffraction intensity I(220) from (220) plane as the orientation except for the Cube orientation are measured using a normal X-ray diffraction method, and the ratio of these X-ray diffraction intensities (X-ray diffraction peak ratio), I(200) / I(220) can be determined from these.

[0136]The texture of a normal copper alloy sheet is composed of a fairly large number of orientation factors and when the constituent ratio of these factors is varied, the plastic anisotropy of the sheet material and the stress relaxation resistance characteristic are...

third embodiment

(3) Best Mode for Carrying Out Third Embodiment of the Present Invention

[0181]In the next place, the third embodiment of the present invention is described in detail below.

[0182](Measurement of Orientation Distribution Density)

[0183]In the third embodiment of the present invention, the distribution density of B orientation and the sum of distribution densities of B orientation, S orientation and Cu orientation are measured by a crystal orientation analysis method using an electron backscatter diffraction pattern EBSP through a field emission scanning electron microscope FESEM.

[0184]In specifying the orientation density of each of these orientations, the orientation density is measured by a crystal orientation analysis method using EBSP, because for enhancing the stress relaxation resistance characteristic or bendability while maintaining high strength, this is affected by the texture (aggregate texture) in a more microscopic region of the sheet (sheet surface). In the crystal orient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| 2θ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com