Regenerative thermal oxidizer for the reduction or elimination of supplemental fuel gas consumption

a regenerative thermal oxidizer and supplemental fuel technology, applied in the field of biogas applications, can solve the problems of limited industrial application level as waste treatment technology, low process efficiency, high capital cost, etc., and achieve the effect of reducing or eliminating supplemental fuel gas consumption and maximizing product methane recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In the following paragraphs, the present invention will be described in detail by way of example with reference to the attached drawings. Throughout this description, the preferred embodiment and examples shown should be considered as exemplars, rather than as limitations on the present invention. As used herein, the “present invention” refers to any one of the embodiments of the invention described herein, and any equivalents. Furthermore, reference to various feature(s) of the “present invention” throughout this document does not mean that all claimed embodiments or methods must include the referenced feature(s).

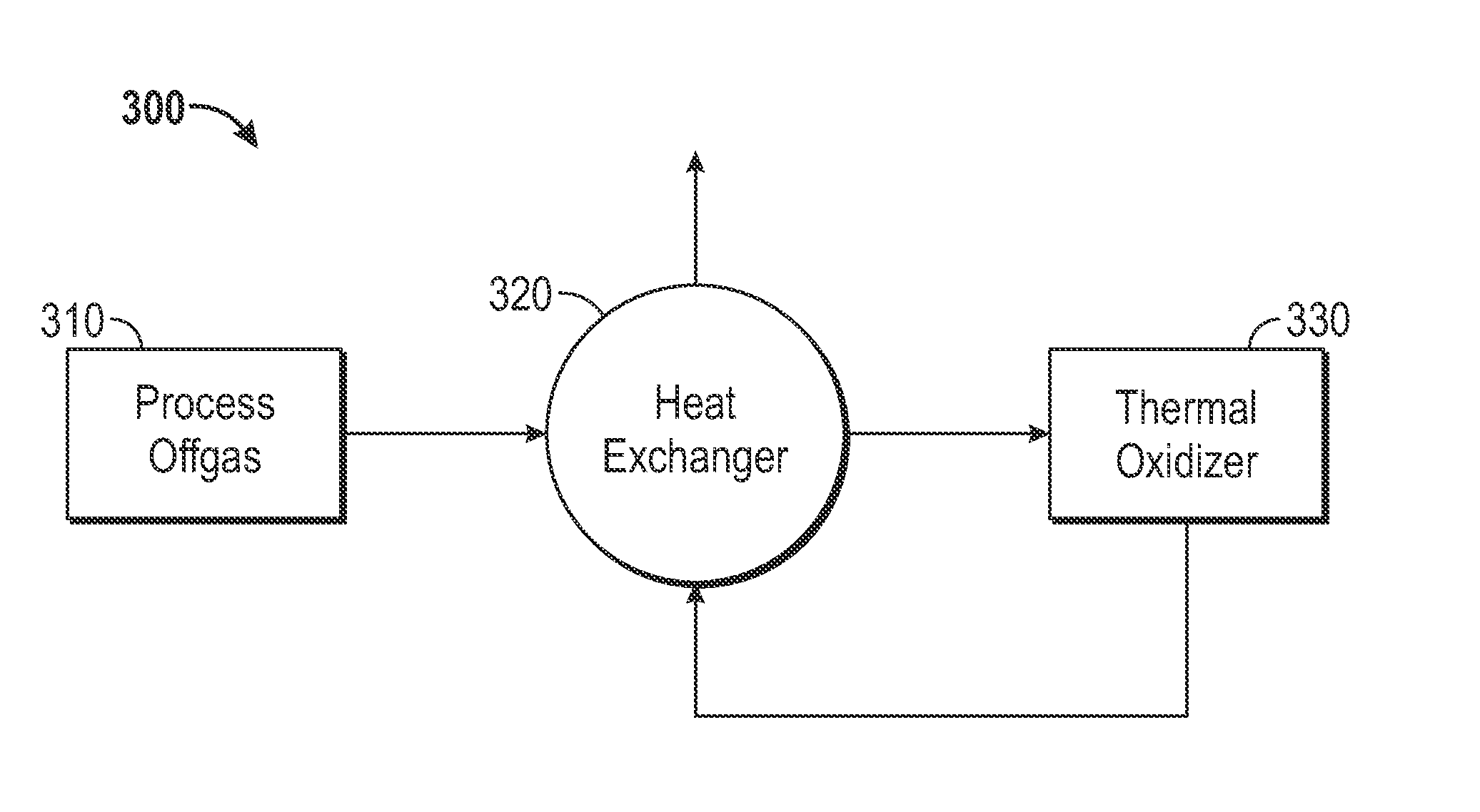

[0018]Biogas is a renewable energy composed primarily of methane resulting from the natural decomposition of organic waste by anaerobic bacteria. Similar to natural gas, methane captured by a biogas system can be used to provide heat, electrical power or transportation biofuel. Biogas extraction can be used to: (i) produce green and renewable energy; (ii) reduce poll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com