Aluminum Die Casting Alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

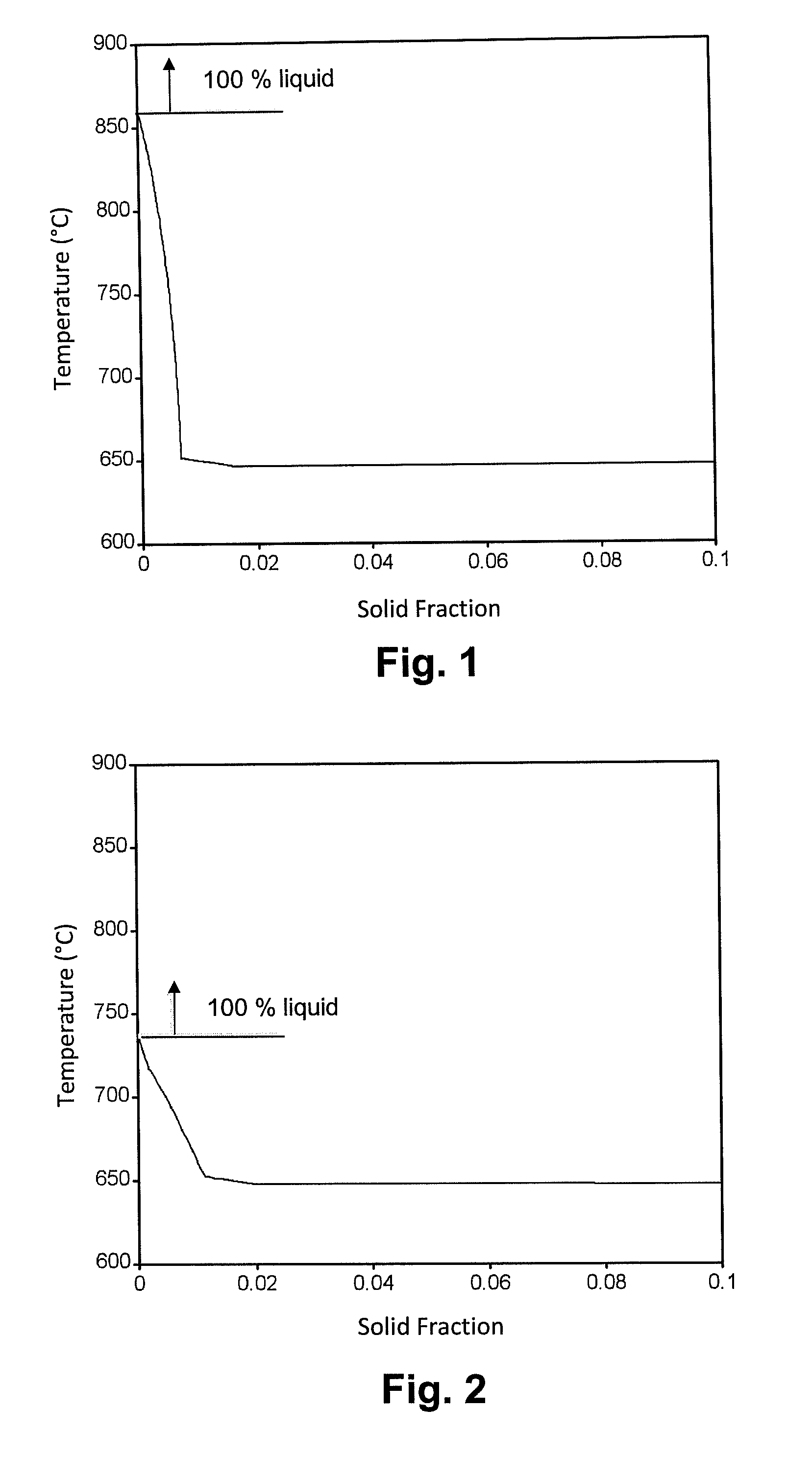

[0035]Dispersion strengthening of aluminum alloys relies on the creation of dispersed particles in the alloy's matrix. This strengthening mechanism is typified by alloys based on the aluminum-nickel system. Hypo-eutectic and eutectic aluminum-nickel alloys solidify in a structure that contains a fine dispersion of nickel tri-aluminide (Al3Ni) particles in a matrix comprised of a solid solution of nickel in aluminum (α-aluminum). Since nickel tri-aluminide is essentially insoluble in aluminum up to about 855° C., aluminum-nickel alloys are more stable at elevated temperatures than aluminum-silicon alloys. However, aluminum-nickel binary alloys do not posses adequate mechanical properties for most automotive applications as their room temperature tensile yield strength does not exceed 80 MPa; and therefore additional strengthening of these alloys is necessary.

[0036]Precipitation strengthening is a well-known mechanism of strengthening aluminum alloys as typified by alloys based on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com