Optimized process for upgrading bio-oils of aromatic bases

a bio-oil and aromatic base technology, applied in the direction of hydrocarbon oil treatment products, organic chemistry, chemistry apparatus and processes, etc., can solve the problems of difficult storage and use of bio-oil, difficult post-treatment storage and use, poisoning post-treatment catalysts, etc., to maximize naphtha, increase the yield of naphtha fraction, and excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

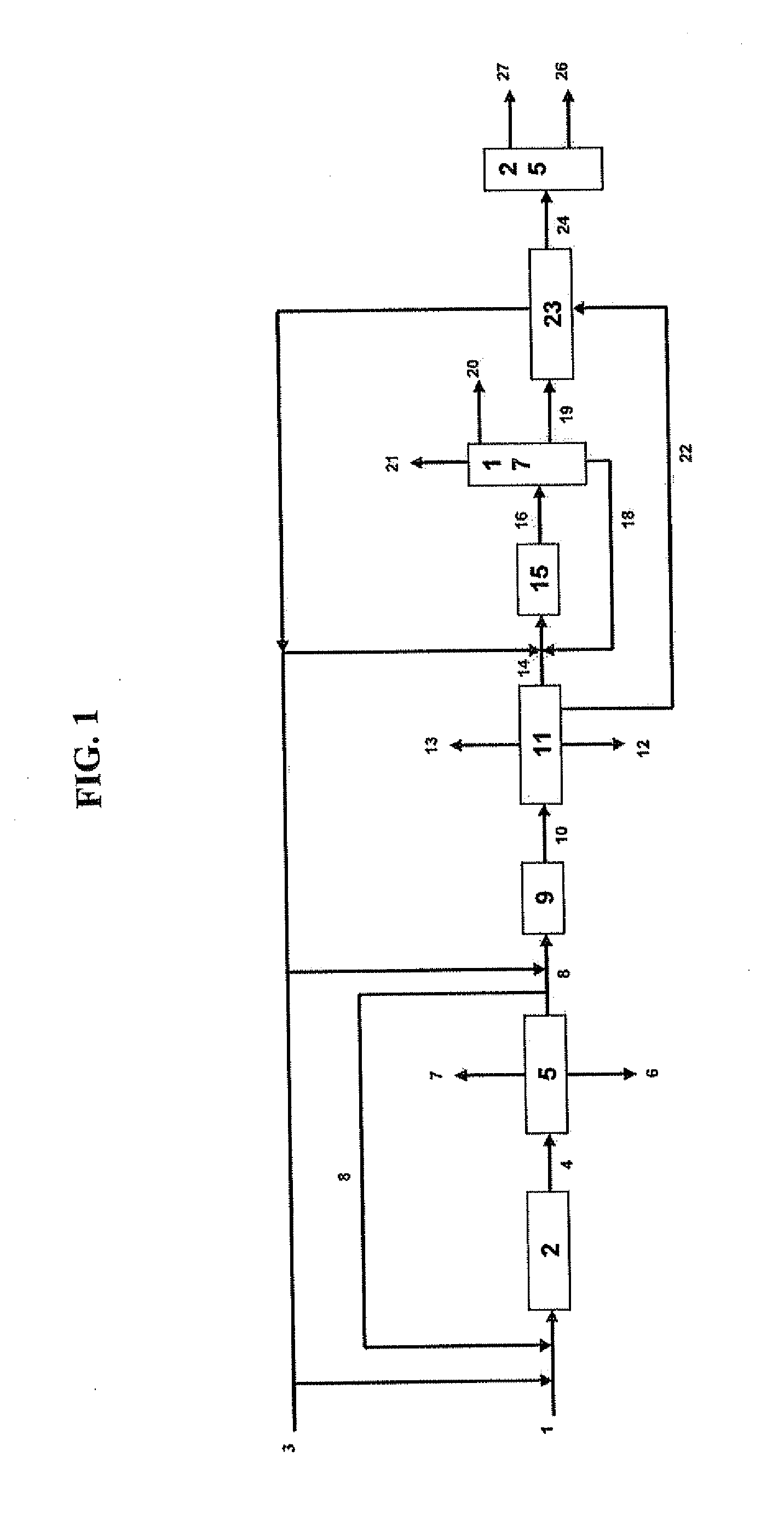

Image

Examples

example 1

Preparation of C1 Hydroreforming Catalysts

[0144]The C1 catalyst is a catalyst of formulation NiCr / C. The precursors of nickel and chromium, in their nitrate form (respectively Ni(NO3)2 and Cr(NO3)3), are provided by Aldrich. The substrate is an activated carbon in the form of cylindrical extrudate provided by the Norit Company (RX3 Extra). This C1 catalyst is obtained by dry impregnation with an aqueous solution that contains the precursors of nickel and chromium. The solution volume is equal to the volume of water uptake of the substrate (i.e., the maximum water volume that can penetrate into its porosity). The concentrations of nickel and chromium precursors in solution are determined in such a way as to obtain the target contents on the final catalyst: 10% by weight of nickel and 5% by weight of chromium. After impregnation of this aqueous solution, the catalyst is allowed to mature at ambient temperature for 4 hours in a water-saturated chamber and then dried in an oven at 70° C...

example 2

Production of a Reformate that Contains More than 70% by Weight of Aromatic Compounds from a Non-Pretreated Bio-Oil

[0145]This example illustrates the production of an oxygen-free reformate that contains more than 70% by weight of BTX aromatic compounds from the treatment of a non-pretreated bio-oil liquid feedstock with the characteristics that are described in Table 1, according to the process of the invention.

[0146]For the first hydroreforming stage, the non-pretreated bio-oil is first introduced, mixed with an organic liquid phase that is obtained from the hydroreforming stage, according to a 1:3 ratio (organic liquid phase:bio-oil) simulating a recycling rate of 0.33, in the autoclave reactor with a hydroreforming catalyst.

[0147]15 g of C1 catalyst prepared according to Example 1 is reduced in a reduction cell at 300° C. for 3 hours in 30 NL / h of hydrogen and then introduced, in a glove bag under inert atmosphere, into a basket that is placed in the autoclave reactor with 75 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com