Method of cooling boil off gas and an apparatus therefor

a technology of boil gas and apparatus, which is applied in the direction of waterborne vessels, gas/liquid distribution and storage, lighting and heating apparatus, etc., can solve the problems of limiting the space available, affecting and affecting the use of closed refrigeration systems, etc., to achieve the effect of improving the co-efficient of performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

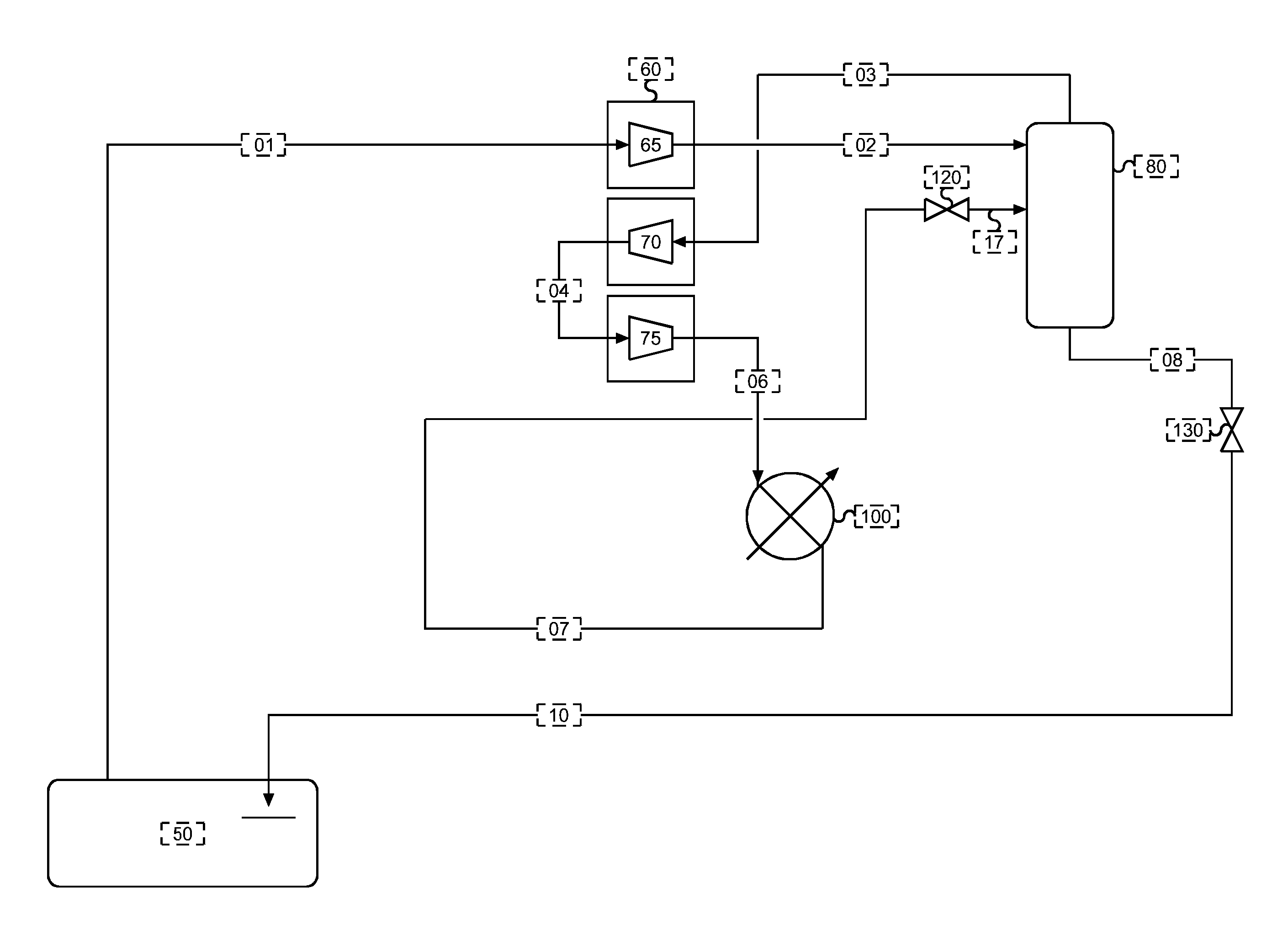

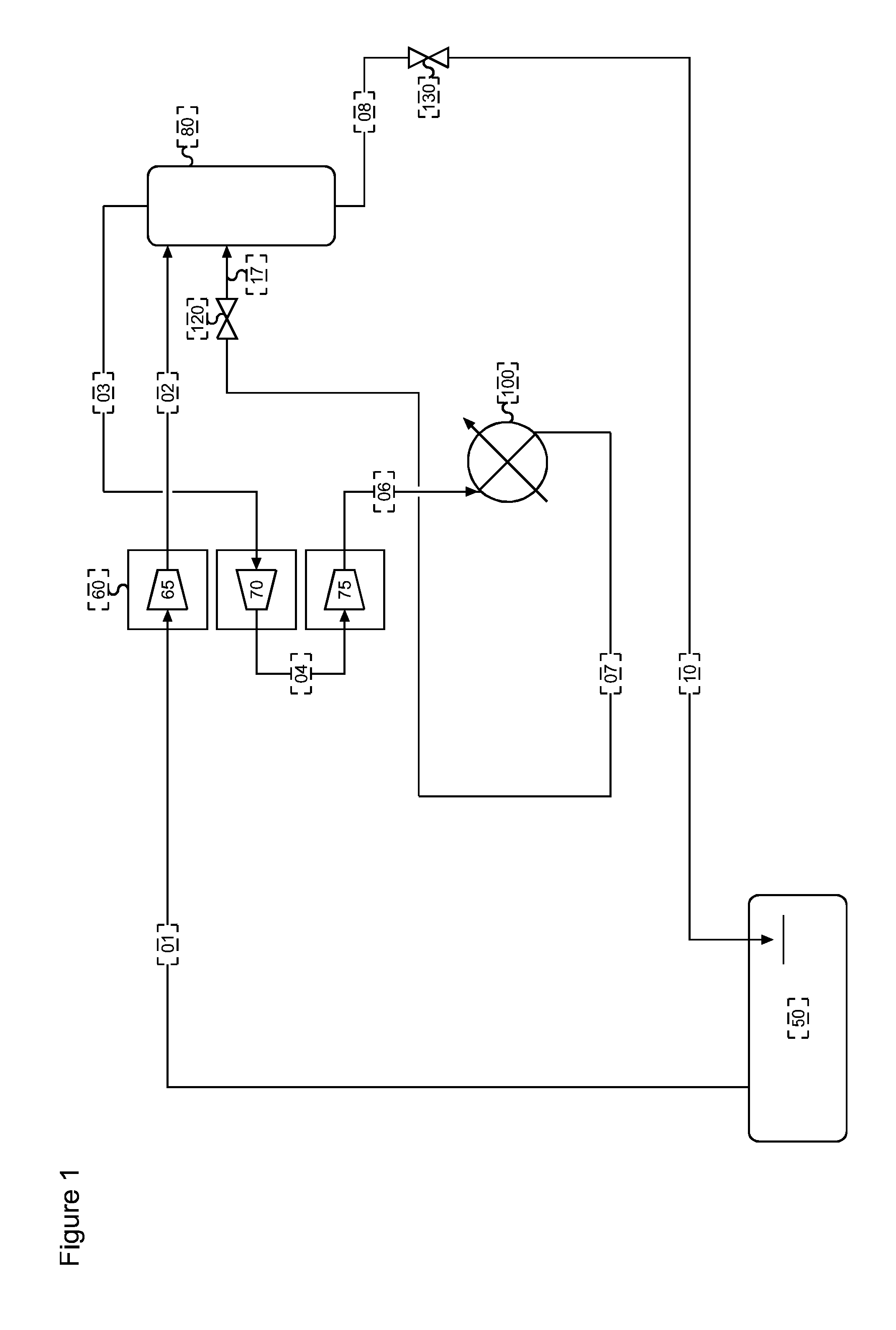

Image

Examples

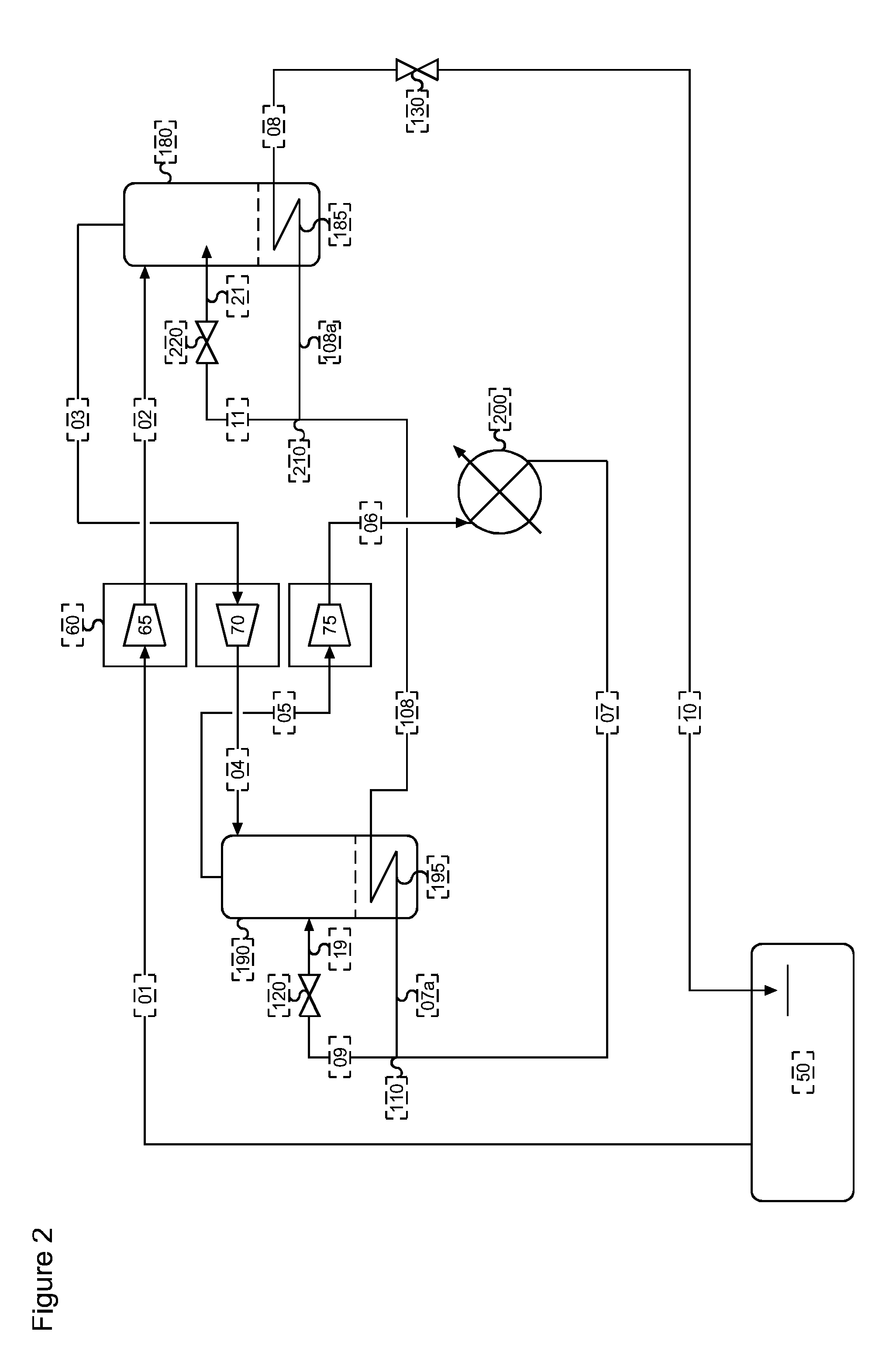

example

[0092]This Example provides a hypothetical calculation of the power requirements, cooling capacity and coefficient of performance of two LPG re-liquefaction systems, namely a system according to the present disclosure in which flash liquid subcooling is carried out on the first and second intermediate compressed BOG streams (i.e. the embodiment of FIG. 3 in which flash liquid subcooling is also carried out in the first intermediate stage economizer) and a comparative system in which flash liquid subcooling is only carried out on the first compressed intermediate stream (i.e. FIG. 2 without a first further heat exchanger / second intermediate stage economizer).

[0093]Compression system data was based upon a three-stage compressor (Burckhardt Compression AG, Winterthur, Switzerland). The liquefied petroleum gas cargo comprised 5.0 mol % ethane and 95.0 mole % propane in the liquid phase. The vapor phase composition of the boil off gas at a tank storage pressure of 0.4 bar gauge was calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com