Liner-provided cap and cap-provided threaded container

a technology of threaded containers and liner caps, which is applied in the direction of caps, applications, liquid handling, etc., can solve the problems of unfavorable material yield rate, poor oxygen barrier property of produced caps, and increase in the weight of the liner, etc., and achieves low opening torque, excellent openability, and easy engagement with the cap shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0085]Hereinafter, an embodiment of the liner-provided cap and the cap-provided threaded container according to the present invention will be described with reference to FIGS. 1 to 3.

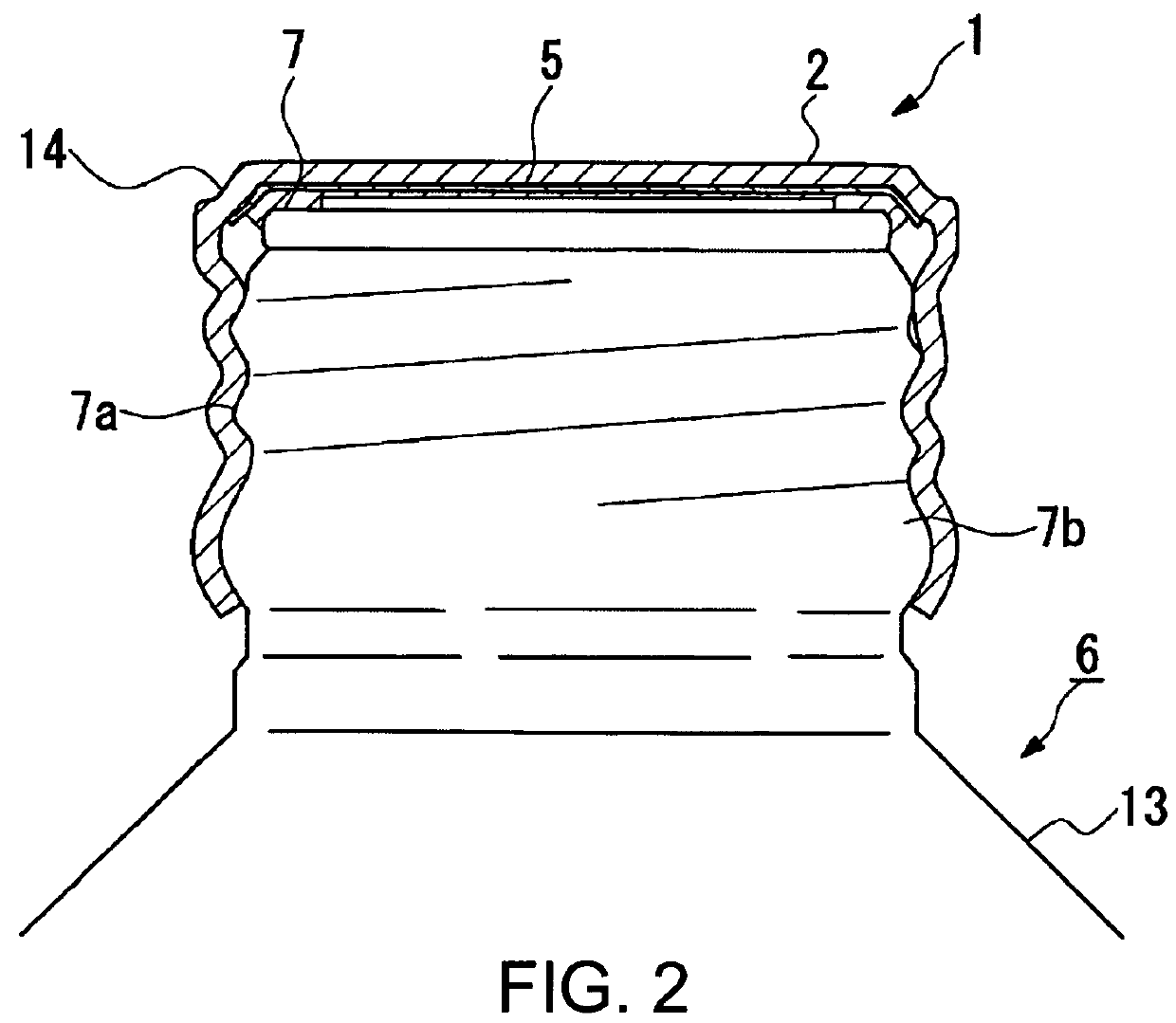

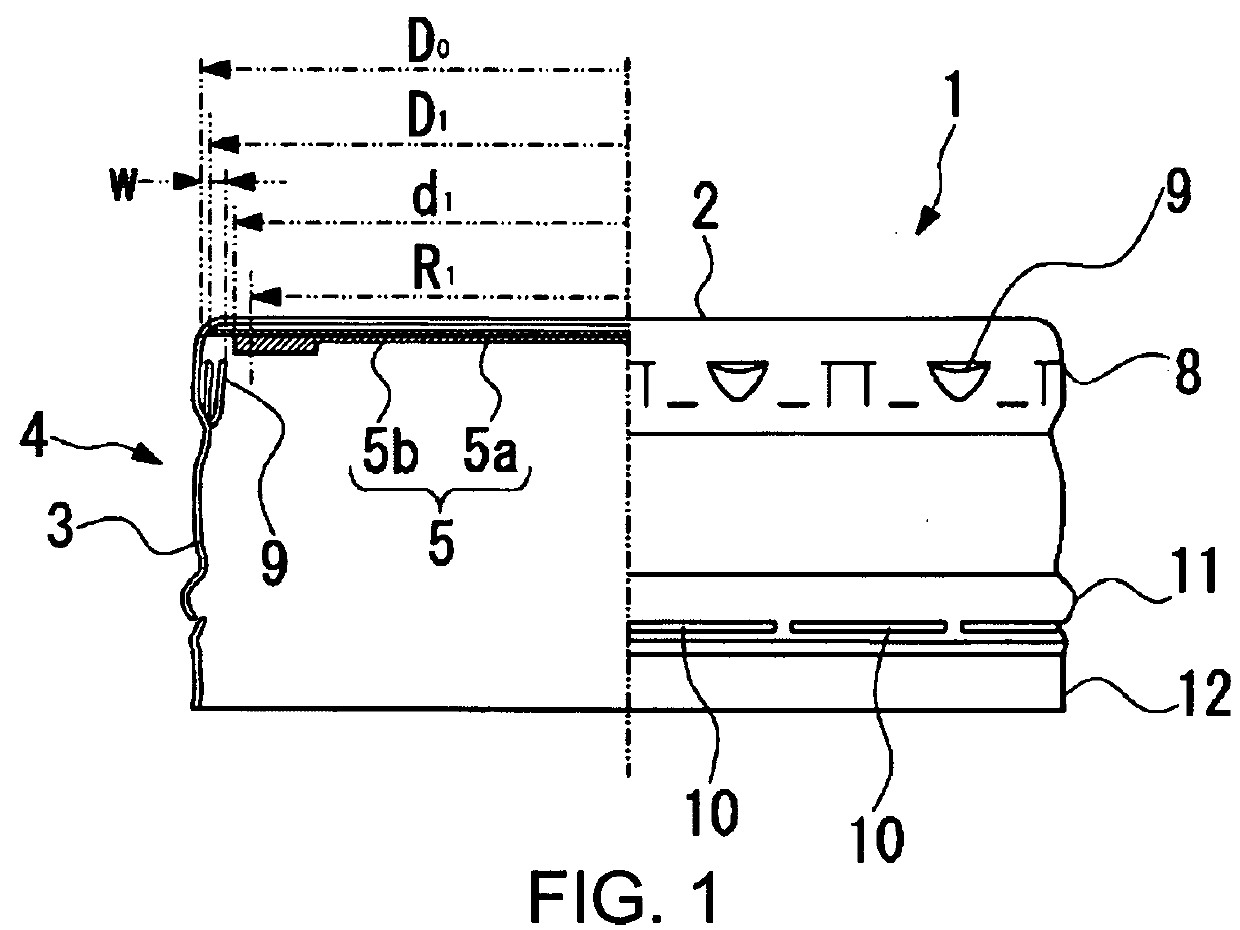

[0086]As shown in FIGS. 1 and 2, the cap 1 of the present embodiment includes a bottomed cylindrical metallic cap shell (cap body) 4 consisting of a top plate 2 and a tubular peripheral wall section 3 that hangs from peripheral edge of the top plate 2; and a tabular synthetic resin liner 5 provided not to fall off from the inner surface of the top plate. A cap-provided threaded container, for example, bottle (container) 6 of the present embodiment is provided with the cap 1 seamed to a mouthpiece (mouth) 7. Examples of the threaded container of the present invention include a bottle-like container, PET bottle, glass bottle, and the like.

[0087]The cap shell 4 is machined from a sheet made of, for example, aluminum or aluminum alloy, and the sheet used is a coated sheet of which the inner and outer surfac...

example 1

[0150]Next, the results of the comparative test carried out for confirming the effects of the present invention will now be described.

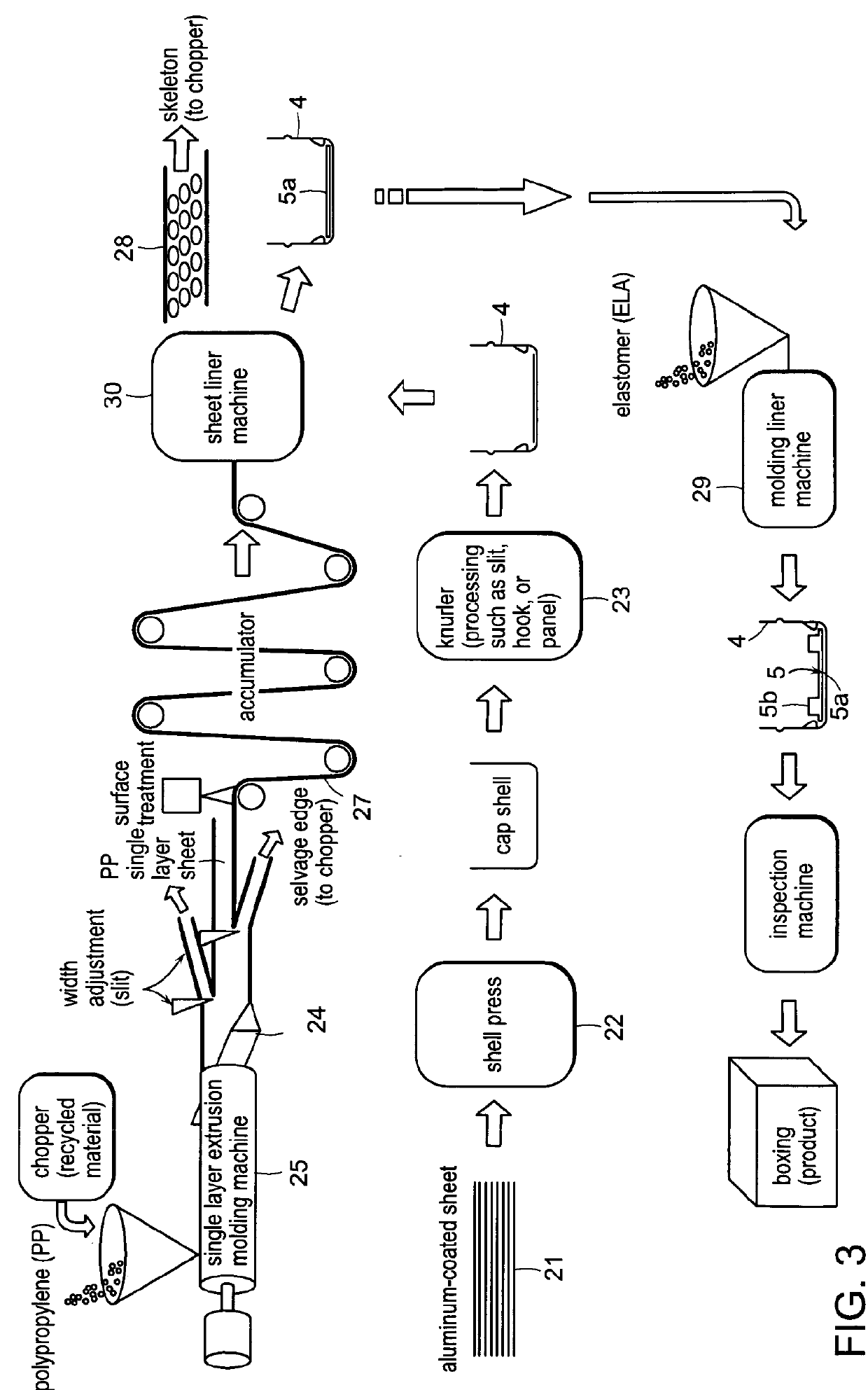

[0151]In this test, an aluminum alloy sheet with a thickness of 0.25 mm with its inner and outer surfaces painted was molded into a cap shell 4 for 38-mm PP cap (pilfer-proof cap). For the cap shell 4, an aluminum sheet of which the inner surface was baking-applied with a polyolefin lubricant-containing epoxy phenol coating material at the rate of 50 mg / dm2 was used. Then, a polypropylene sheet formed by an extruder 25 and T die 24 was punched into a 37.8 mm rigid sheet 5a, and the rigid sheet 5a was inserted into the cap shell 4 having an inner diameter φ of 38.05 mm. In the cap shell 4, the 12 liner locking hooks (liner stopping protrusion 9) protruding toward the interior with a length of 1.0 mm extending substantially horizontally along the top surface was formed. The position of the hook was 1.5 mm in height from the cap's top surface. An automat...

example 2

[0157]The liner of the present invention was produced as in Example 1, and compared with a conventional two-layer liner material as a Comparative Example. In the present invention, a sliding layer (rigid sheet) having a different outer diameter size was produced. After the insertion into a cap shell, a sealing layer (soft layer) was formed by the in-shell mold method. The size of the prototype sliding layer (rigid sheet) was estimated considering the upper limit and the lower limit of the present invention, and the prototype sliding layer was inserted into the cap shell. These were evaluated in the same manner as in Example 1. A conventional two-layer sheet was tested as a Comparative Example. The sheets of Comparative Examples were produced by extruding and laminating PP and styrene elastomer as in Example 1 from the two-layer extruder and the T die of a sheet molding machine, adjusting the thickness thereof by a cold roller, cutting them to a certain width. After cutting, the shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com