High temperature composite projectile barrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

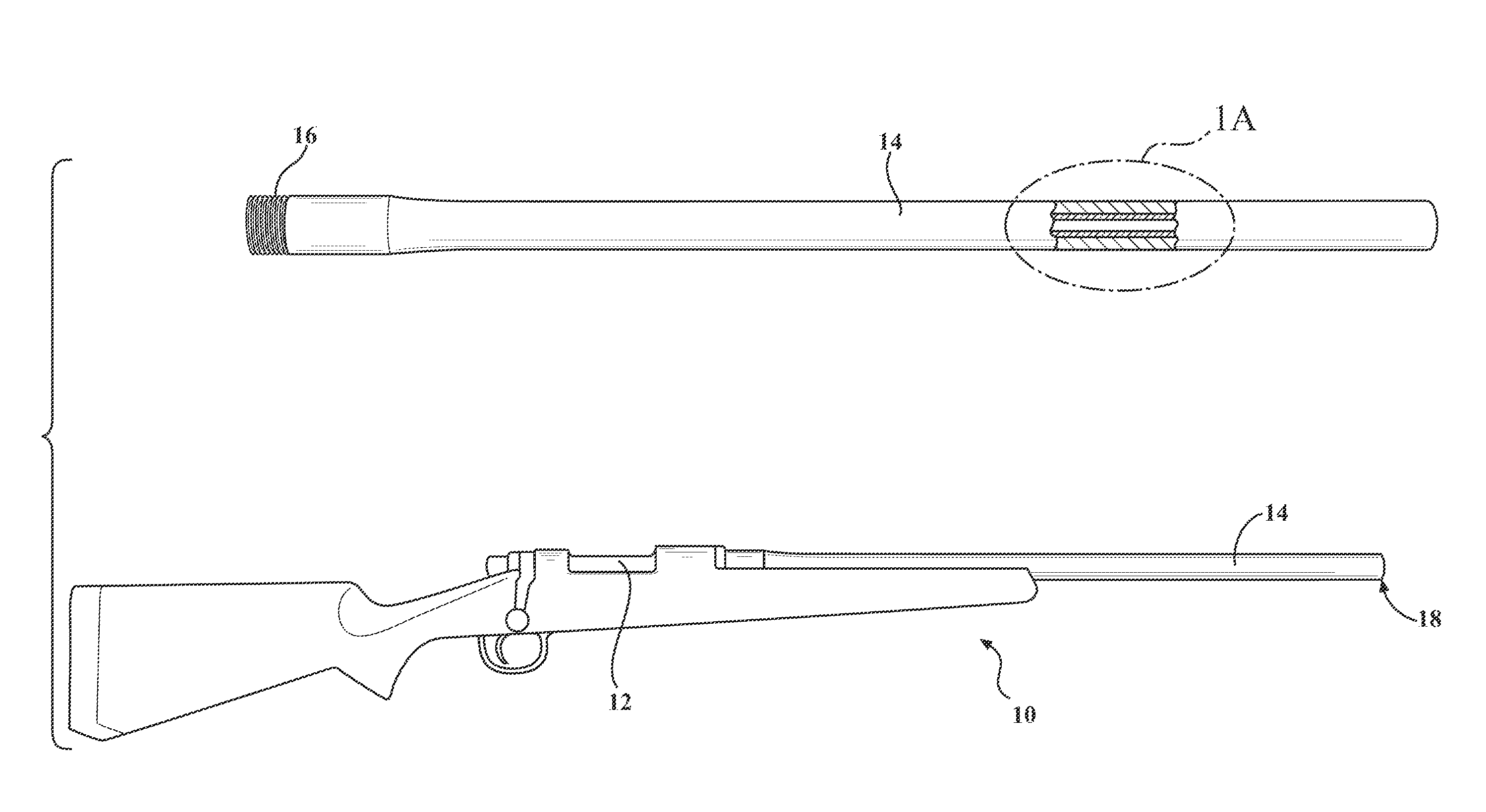

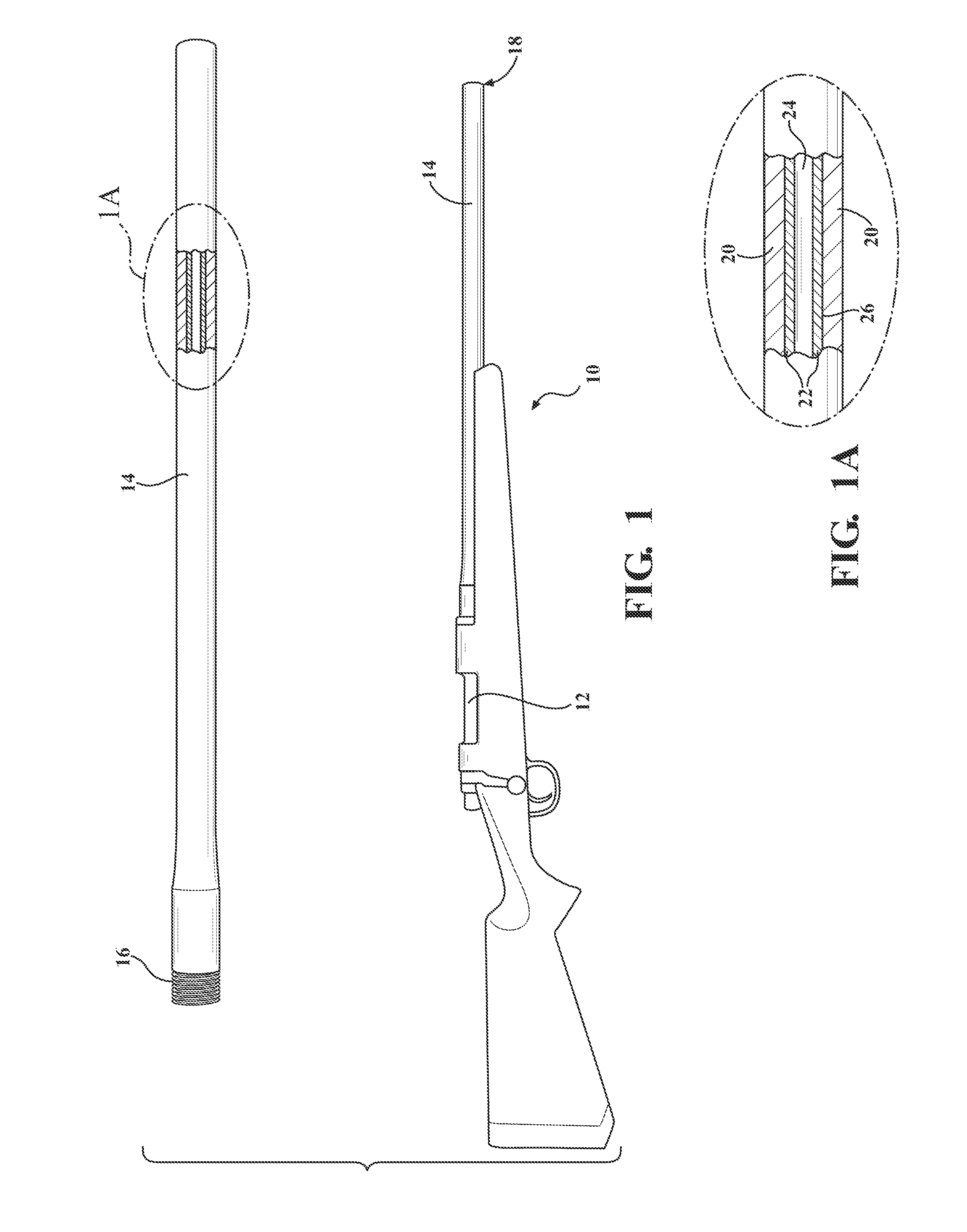

[0023]Referring to the figures, wherein like numerals indicate like or corresponding parts throughout the several views, FIG. 1 shows a bolt action rifle 10 fitted with a receiver 12, stock, trigger, barrel 14, and other familiar features. In the embodiment shown, barrel 14 securely engages with receiver 12 by means of threads 16. In operation, a cartridge of ammunition is inserted into the receiver. The cartridge has a base portion containing a gunpowder charge and dischargeable projectile, i.e., a bullet. When a shooter pulls the trigger, a firing pin strikes the base of the cartridge, igniting the gunpowder charge and causing the bullet to discharge through axial bore 24 and out of the muzzle 18.

[0024]As shown in FIG. 1A, barrel 14 is comprised of an inner liner 22 and an outer shell 20. In one embodiment, inner liner 22 is made of a metal, such as a steel alloy. A metal inner liner, such as stainless steel, facilitates fabrication of rifling lands and grooves along axial bore 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com