TFT substrate manufacturing method and TFT substrate

a thin film transistor and manufacturing method technology, applied in the field of display technology, can solve the problems of mos device failure, deterioration of device performance, and increasing severe hot carrier injection effect, so as to improve tft reliability, reduce threshold voltage drift, and reduce the effect of threshold voltage dri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]To further expound the technical solution adopted in the present invention and the advantages thereof, a detailed description is given to a preferred embodiment of the present invention and the attached drawings.

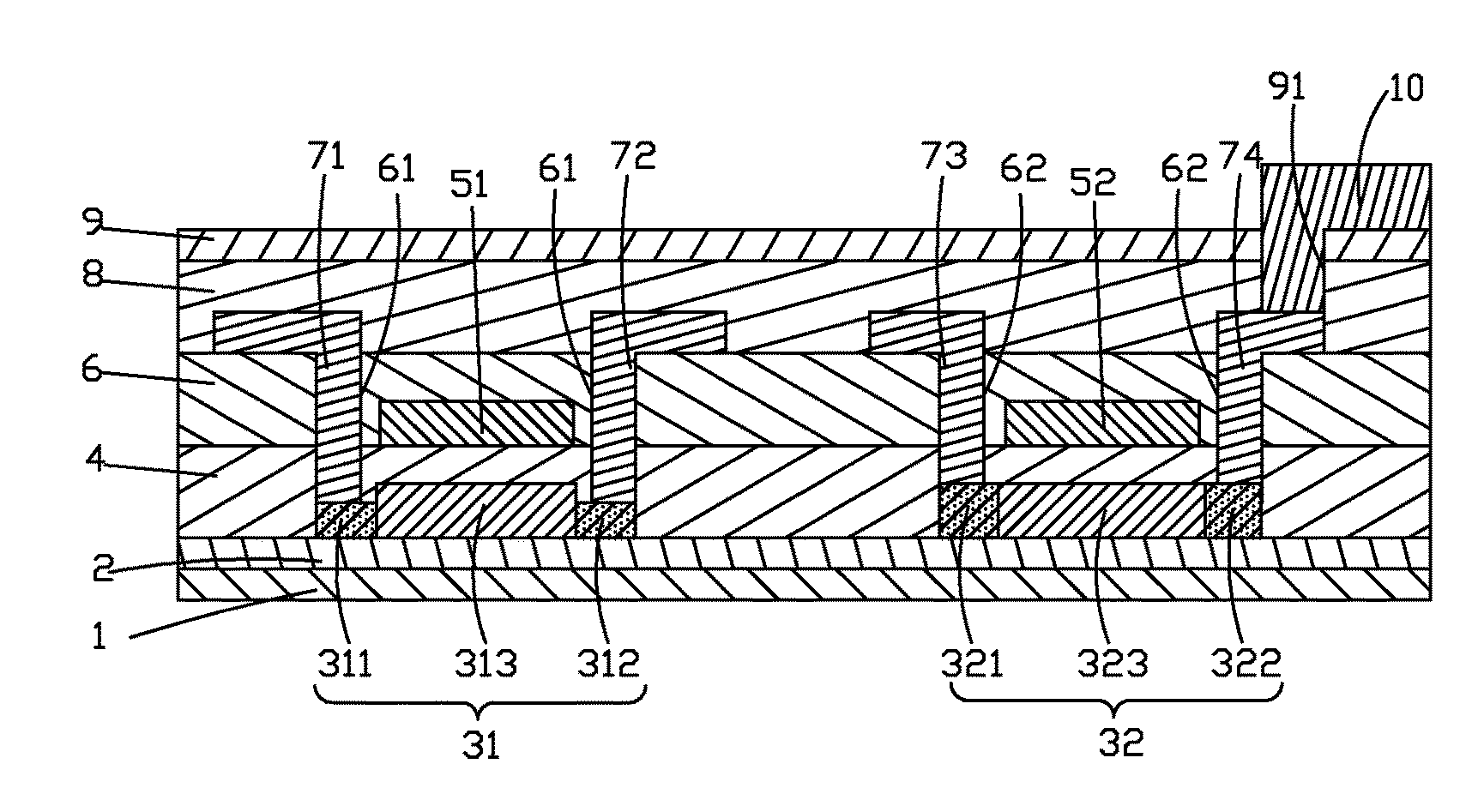

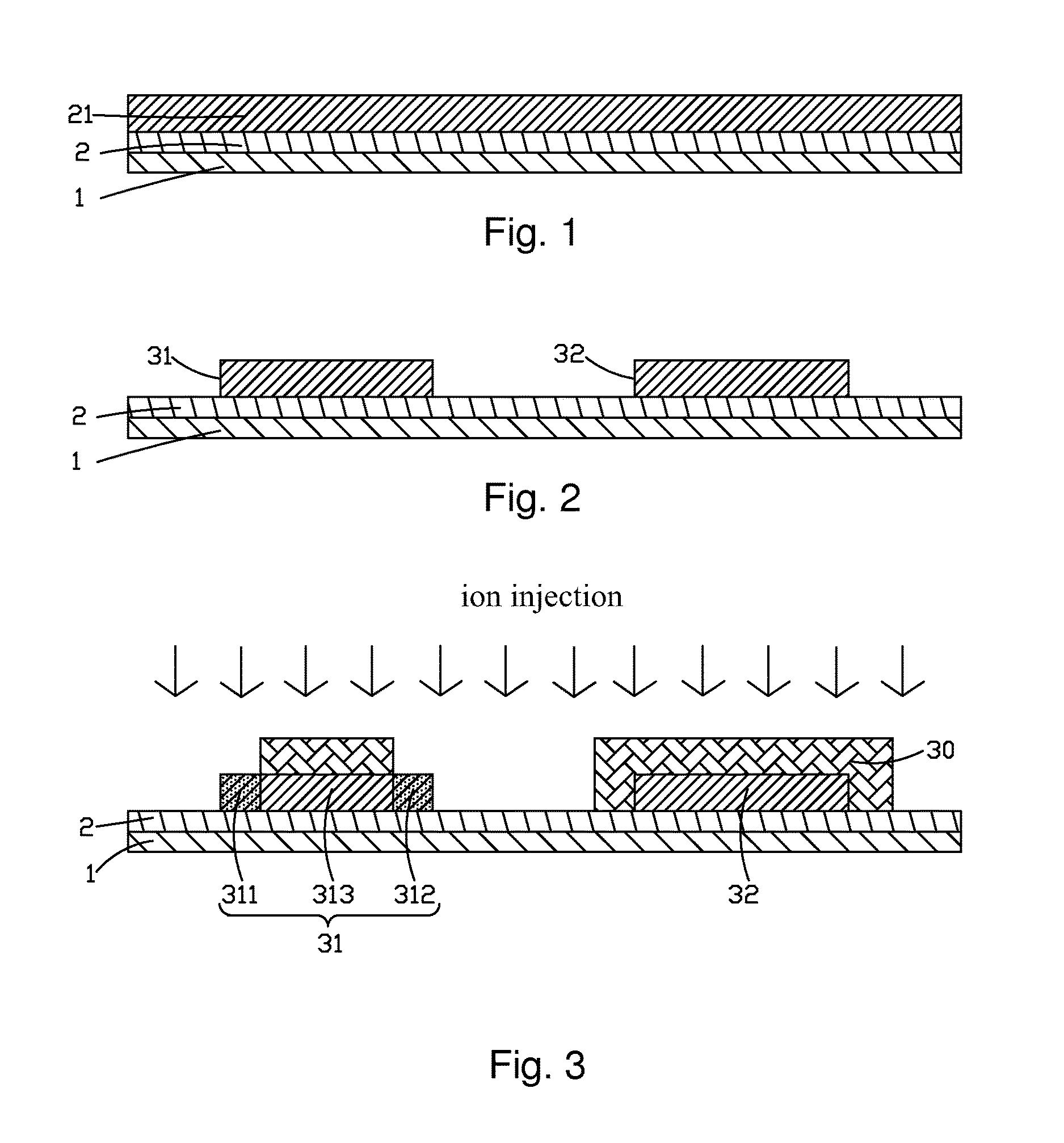

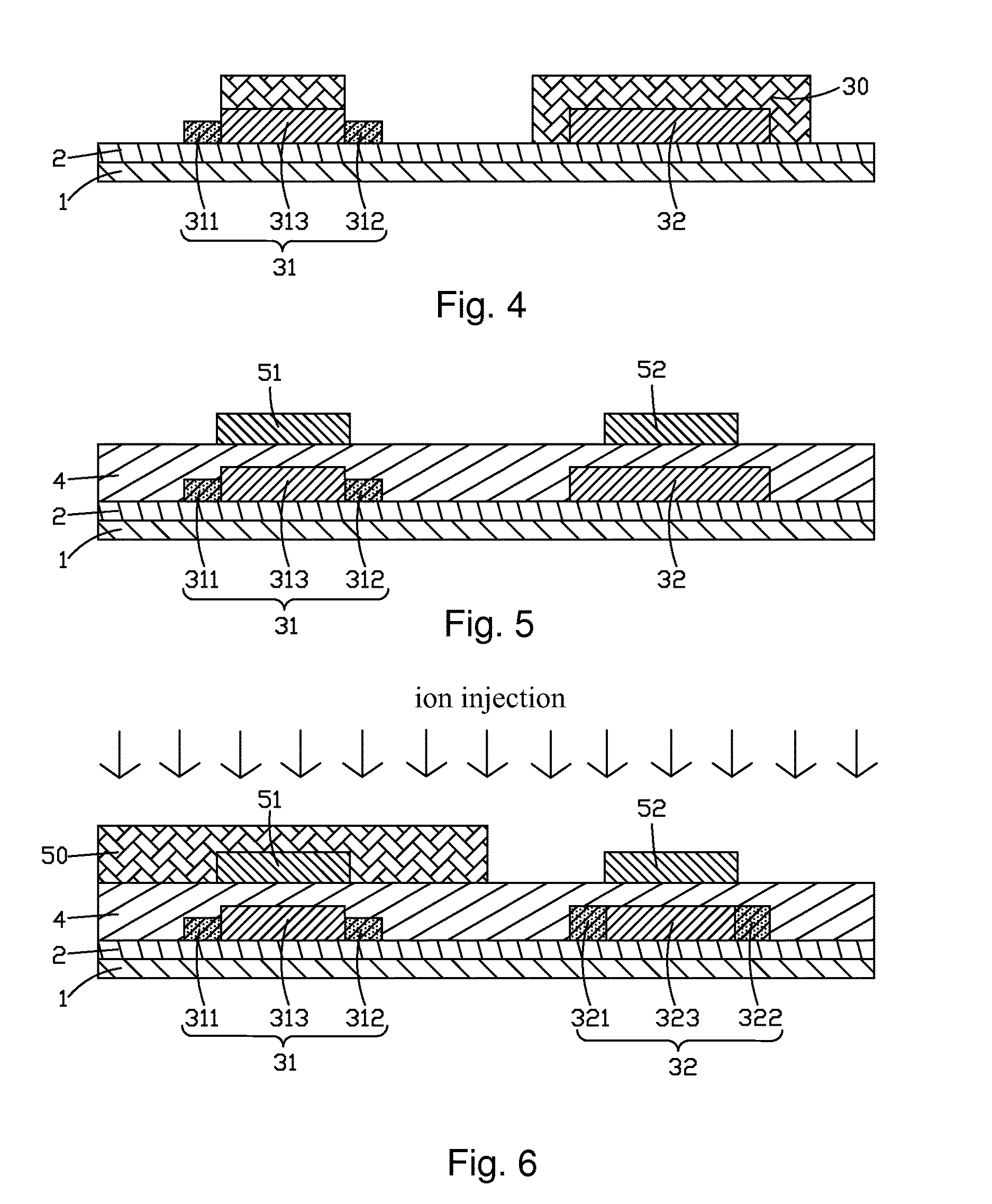

[0059]Referring to FIGS. 1-10, firstly, the present invention provides a thin-film transistor (TFT) substrate manufacturing method, which comprises the following steps:

[0060]Step 1: as shown in FIG. 1, providing a substrate 1 and sequentially depositing a buffer layer 2 and an amorphous silicon layer 21 on the substrate 1.

[0061]Specifically, the buffer layer 2 can be a silicon oxide (SiOx) layer, a silicon nitride (SiNx) layer, or a stacked combination of a silicon oxide layer and a silicon nitride layer.

[0062]Step 2: as shown in FIG. 2, subjecting the amorphous silicon layer 21 to excimer laser annealing (ELA) or solid phase crystallization (SPC) to convert the amorphous silicon layer into a low temperature poly-silicon layer and applying a photolithographic process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com