Metal oxide powder and method for the production of the same

a technology of metal oxide powder and method, which is applied in the direction of chromium oxide/hydrate, lanthanide oxide/hydroxide, niobium compounds, etc., can solve the problems of complex procedures, difficulty in obtaining raw materials, and difficulty in producing metal oxide powder containing less agglomerated particles,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

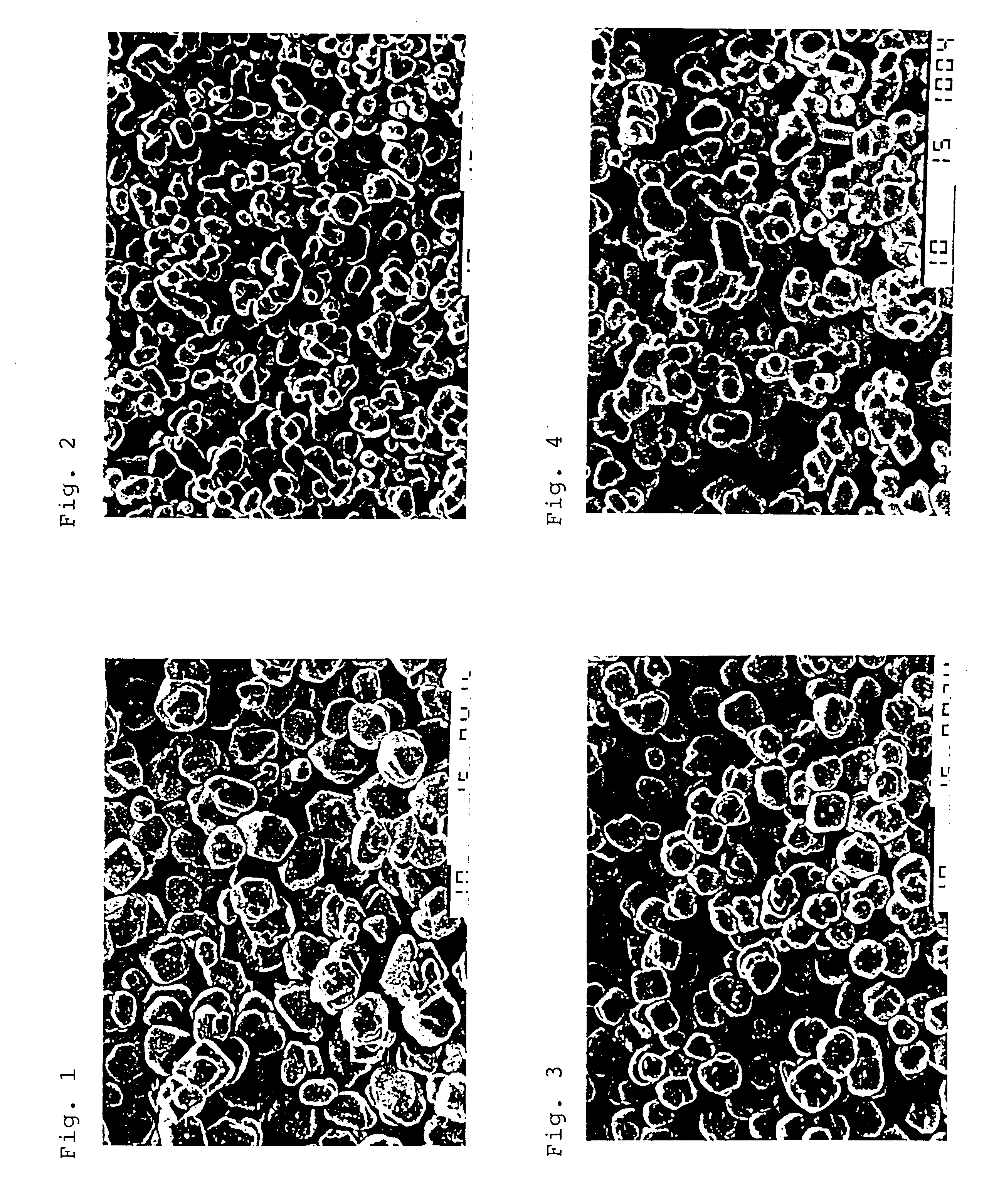

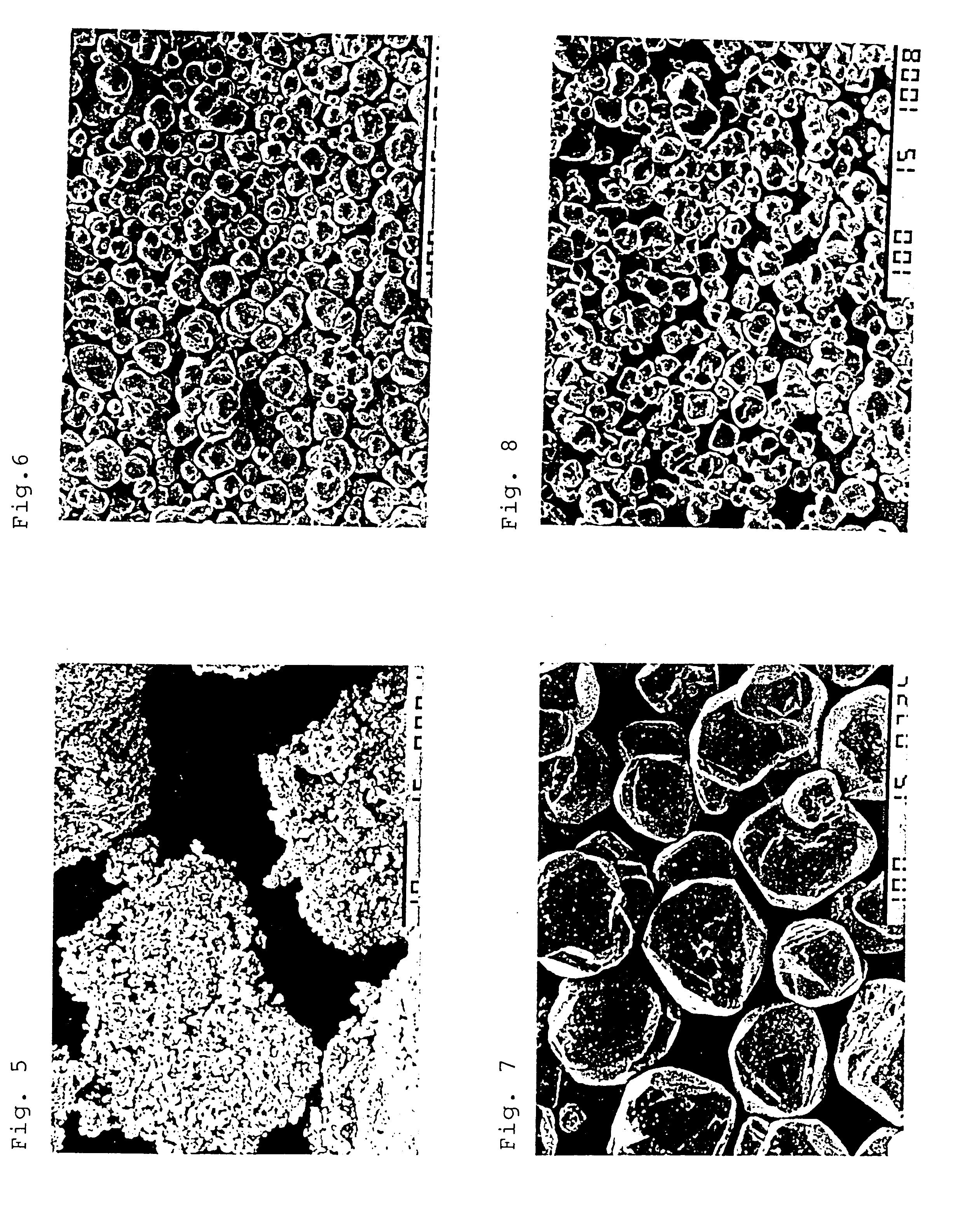

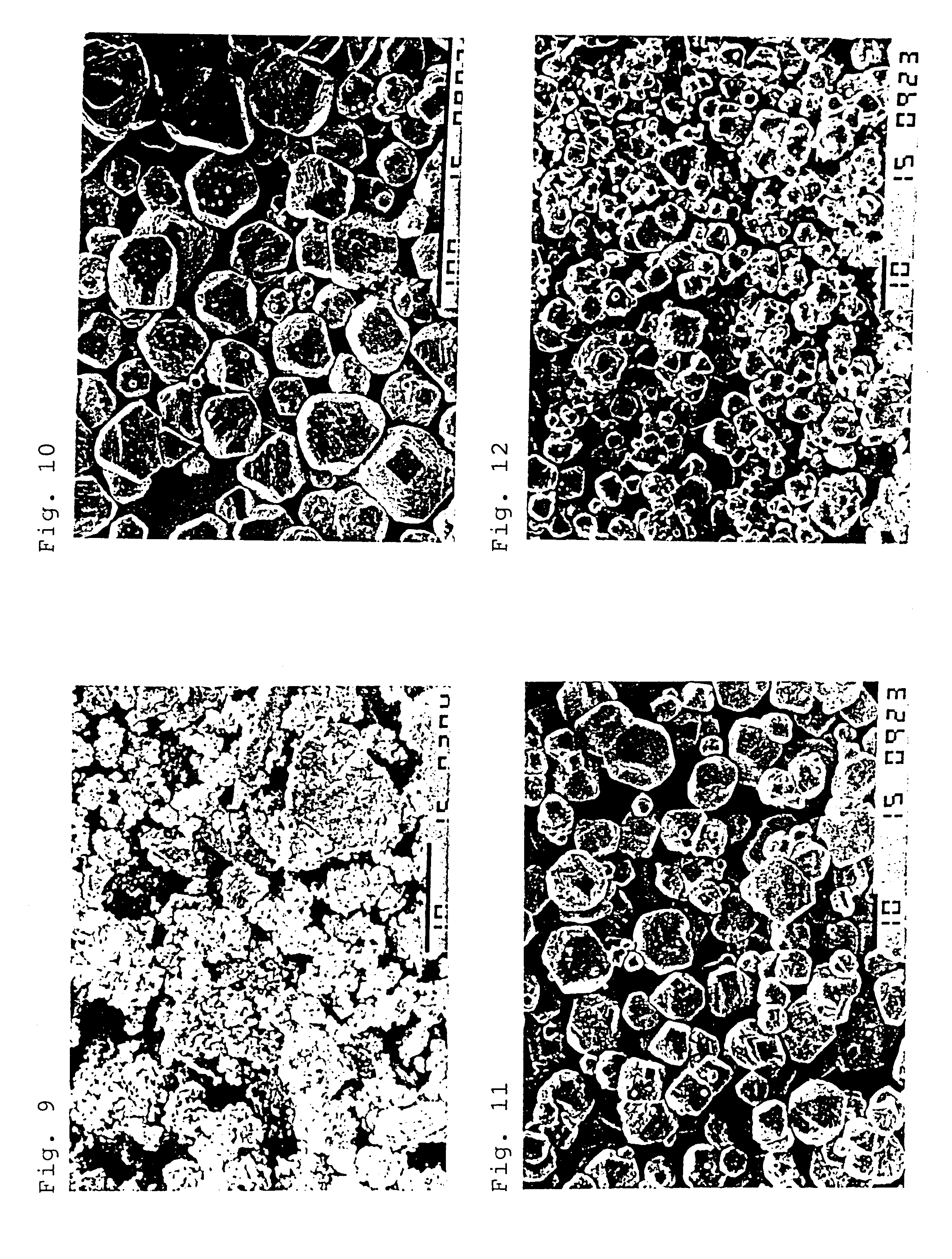

A metatitanic acid slurry (30 wt. % as reduced to titanium oxide weight. A product obtained in an intermediate step of the sulfuric acid method) was concentrated by an evaporator and then dried in an air at 200.degree. C. to obtain raw material titanium oxide powder. This powder had a BET specific surface area of 183 m.sup.2 / g (a primary particle size calculated from the BET specific surface area=0.008 em). According to the X-ray diffraction analysis, the powder was found to be anatase type titanium oxide, and no other peak was observed.

The raw material titanium oxide powder (1.2 g) was filled in an alumina vessel. Its bulk density was 19% of the theoretical density. Then, the powder was placed in the quartz muffle, and heated from room temperature at a heating rate of 500.degree. C. / hr. while flowing the atmosphere gas consisting of 100 vol. % of hydrogen chloride at a linear velocity of 20 mm / min., and calcined at 1100.degree. C. for 30 minutes, followed by spontaneous cooling to...

example 2

In the same manner as in Example 1 except that an atmosphere gas consisting of 10 vol. % of hydrogen chloride and 90 vol. % of nitrogen was used in place of the atmosphere gas of 100 vol. % hydrogen chloride, the rutile type titanium oxide was obtained. The results are shown in Table 1.

example 3

In the same manner as in Example 1 except that an atmosphere gas consisting of 30 vol. % of hydrogen chloride, 10 vol. % of steam and 60 vol. % of nitrogen was used in place of the atmosphere gas of 100 vol. % hydrogen chloride, the rutile type titanium oxide was obtained. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com