Integrated aspheric optical coupler for RF planarized automatic photonics packaging

a technology of automatic photonics and aspheric optical couplers, applied in the field of photonics packages, can solve the problems of reducing device performance at high frequency operation, data can easily be lost, and complicating the assembly process, so as to achieve accurate and reliable alignment of optical fibers, reduce assembly costs, and simple optical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

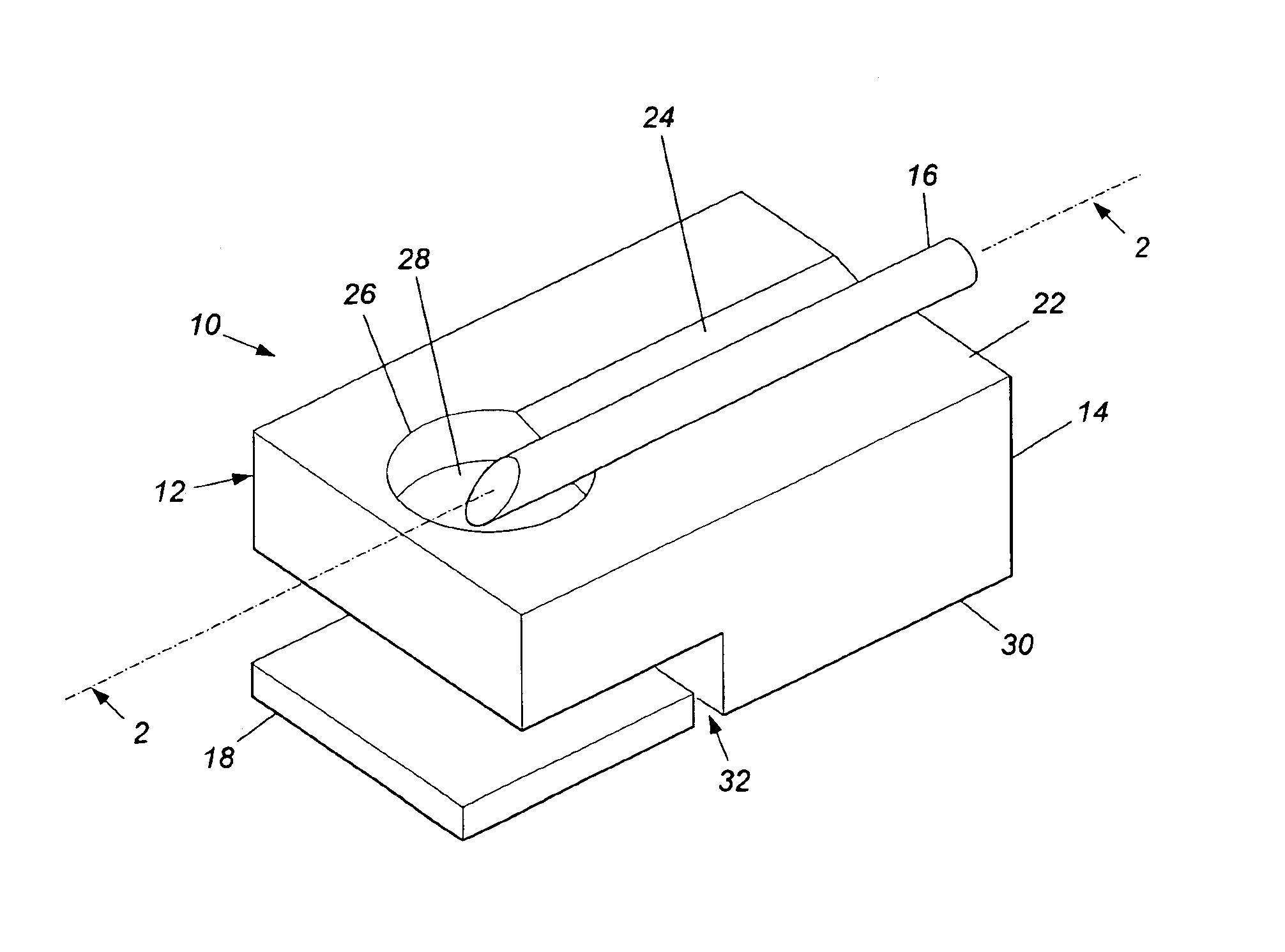

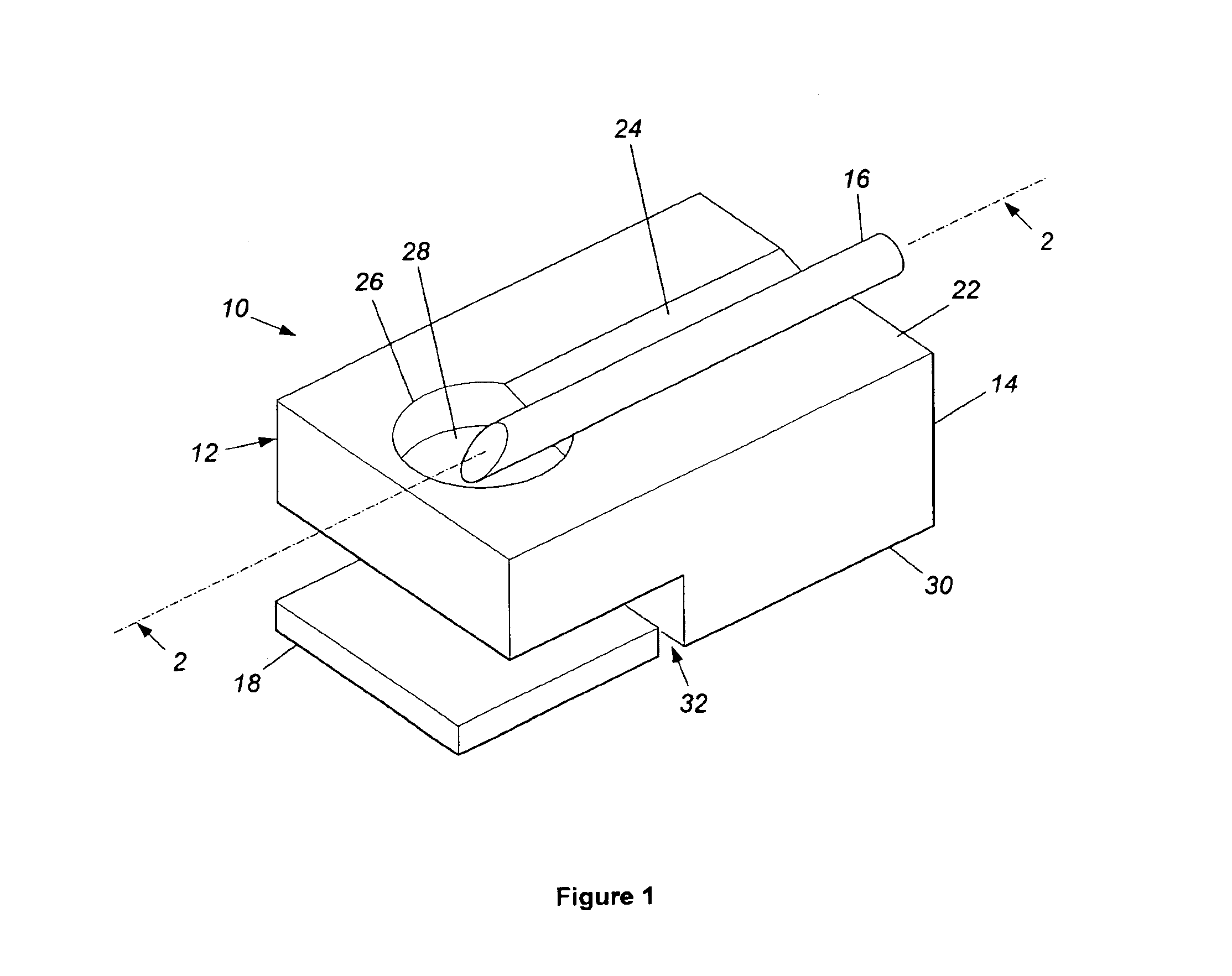

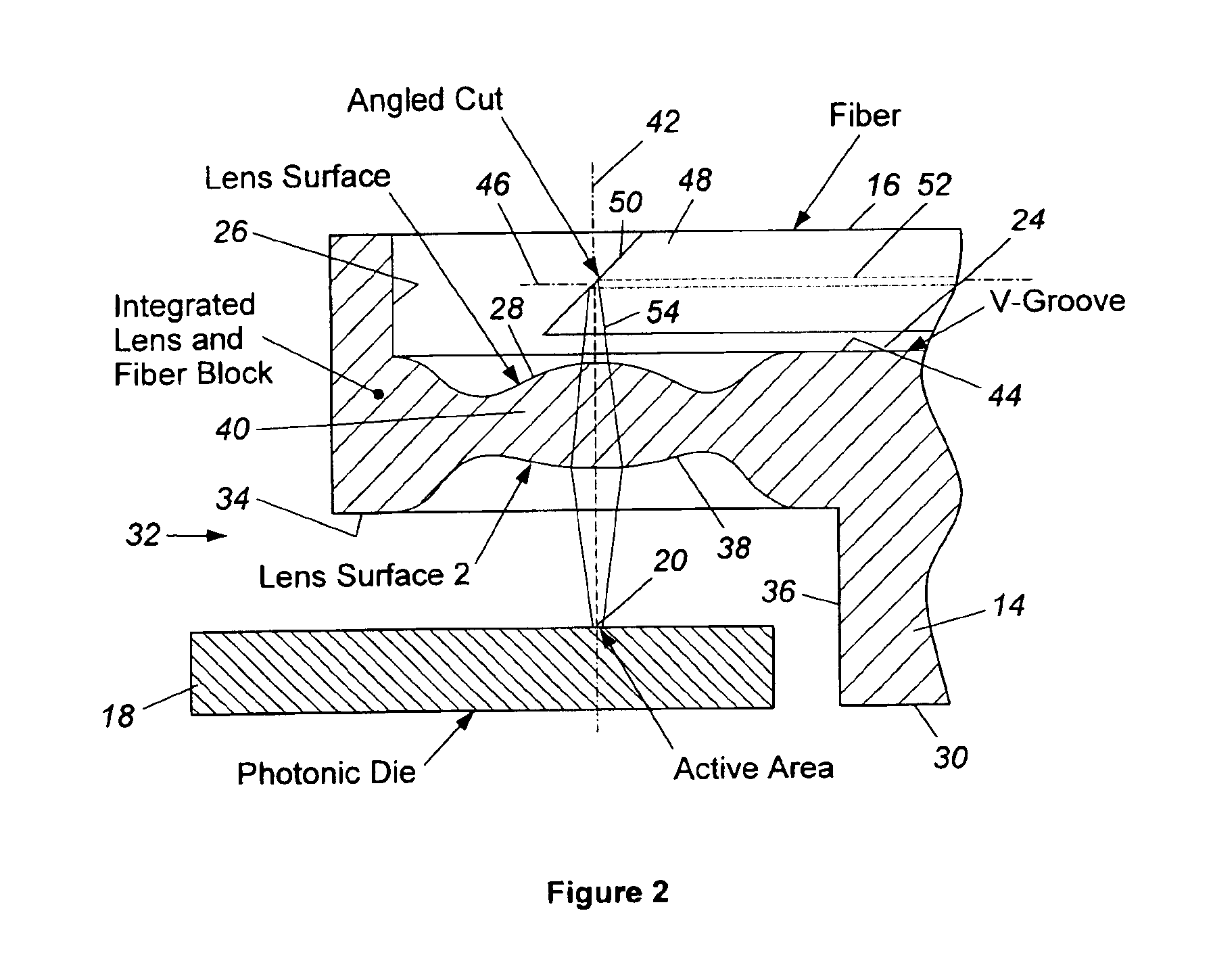

[0018]Turning now to a more detailed description of the present invention, there is illustrated in FIGS. 1, 2 and 3 a photonics package 10 which includes a semiconductor monolithic optical coupler, or alignment device 12 fabricated from a substrate 14 by a standard semiconductor etching process. This process permits fabrication of the specific features needed for the alignment device 12, as will be described below.

[0019]More specifically, the photonics package 10, which may be used, for example, in a communications or data network application for converting optical signals to corresponding electrical signals, or vice-versa, includes the alignment device 12, an optical fiber 16 supported by the alignment device, and a photonic die 18 which includes an optically active region 20, which in one embodiment may be a photodetector. In another embodiment, the region 20 may instead be a light emitter such as a VCSEL or SLED. The alignment device 12 is a monolithic structure that is created (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com