Heat treatment for cold worked nitinol to impart a shape setting capability without eventually developing stress-induced martensite

a technology of cold worked nitinol and heat treatment, which is applied in the field of application of nickeltitanium alloys to medical devices, can solve the problems of non-linear pseudoelasticity and devastating consequences for patients, and achieve the effects of less stress, reduced stress, and reduced stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

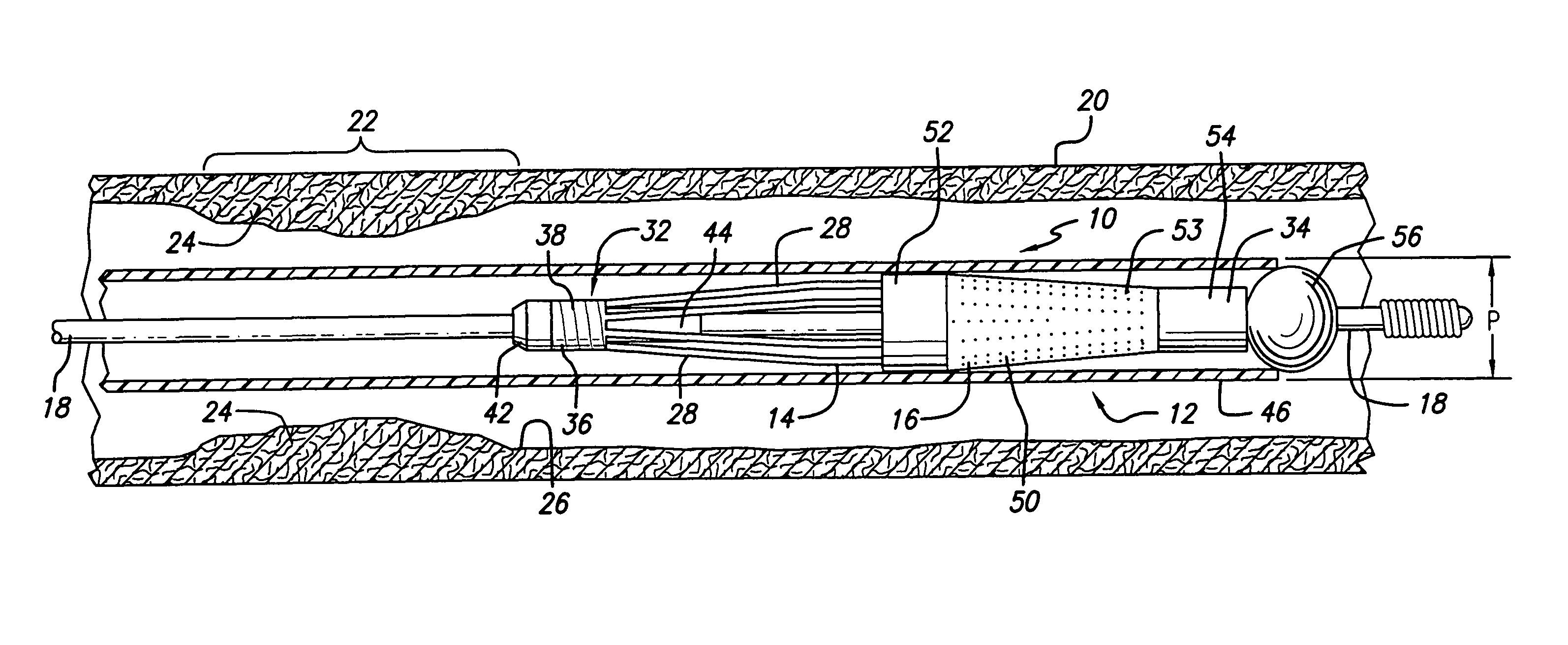

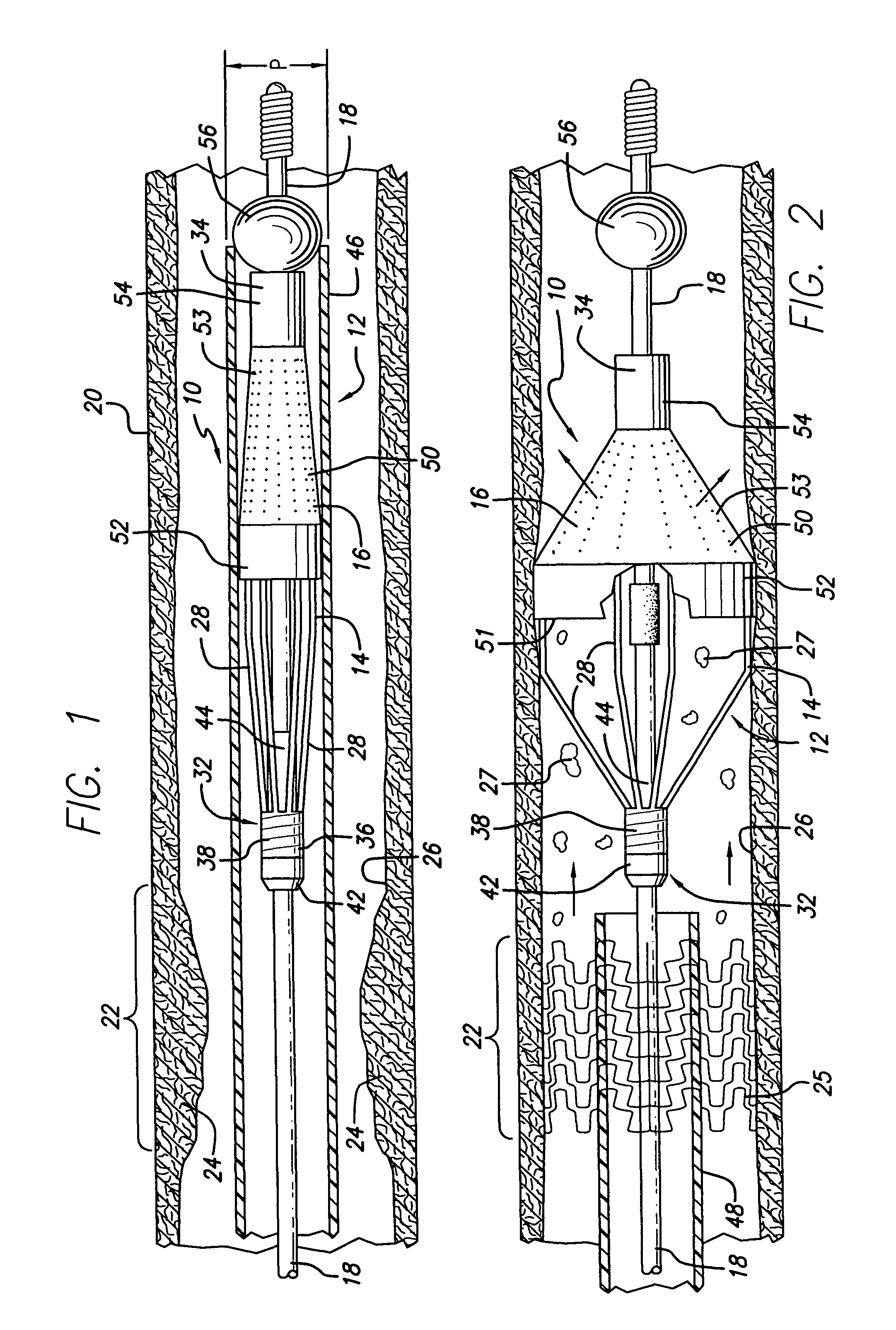

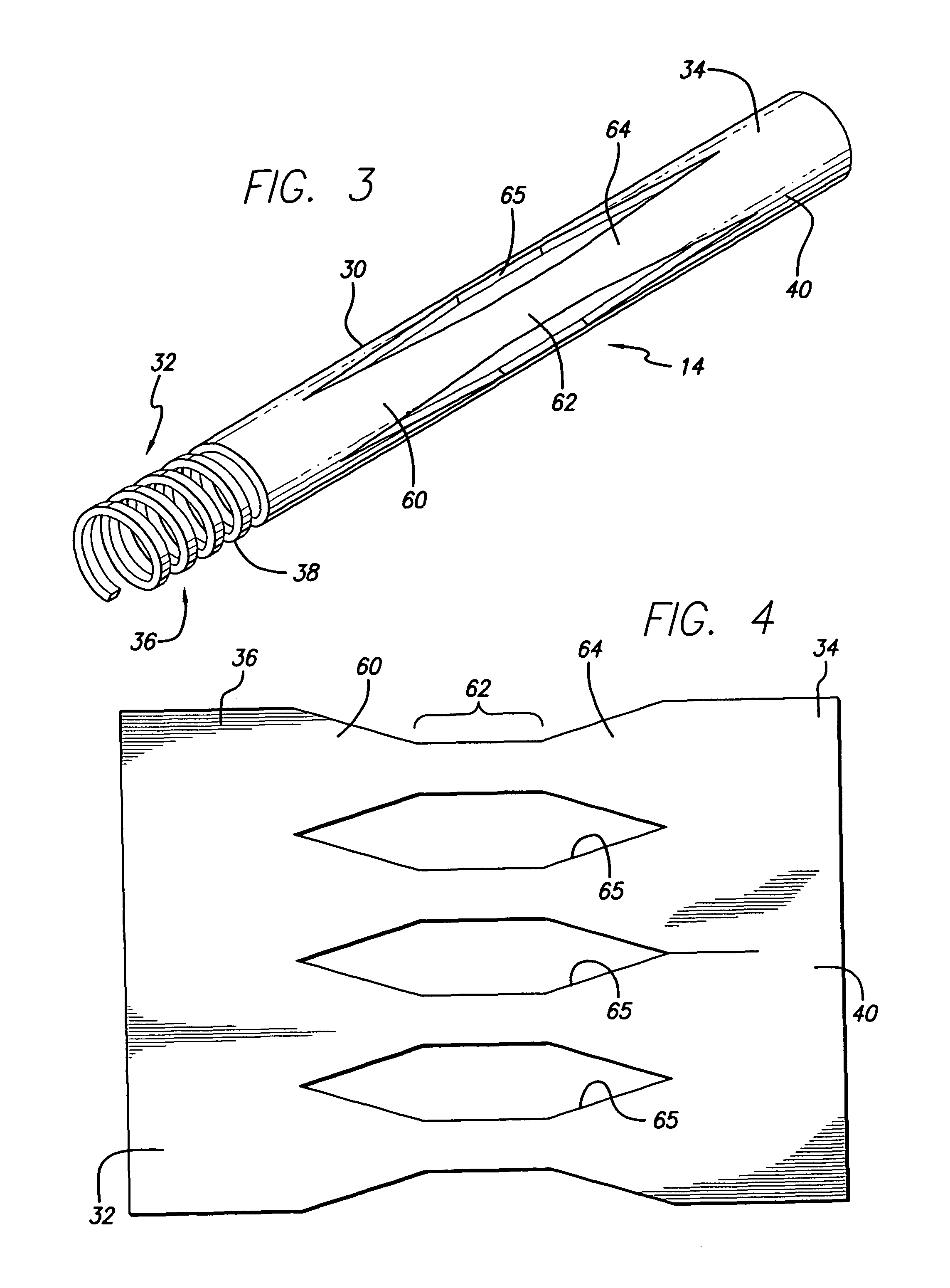

[0023]The present invention is generally directed to cold worked nickel-titanium alloys that have linear'pseudoelastic behavior without a phase transformation or onset of stress-induced martensite as applied to a medical device having a strut formed body deployed from a sheath. Although the present invention is applicable to and contemplates numerous medical devices, for the sake of illustration, the following detail description focuses on an exemplary embodiment involving a filtering device and system for capturing embolic debris in a blood vessel created during the performance of a therapeutic interventional procedure.

[0024]In a preferred embodiment, the present invention medical device has a body formed from struts, wherein the body includes a cold formed nickel-titanium alloy, and the nickel-titanium alloy is in a martensitic phase when the body is stressed into a first shape and also when the stress on the body is relieved to assume a second shape. The preferred embodiment furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pseudoelastic behavior | aaaaa | aaaaa |

| pseudoelastic” behavior | aaaaa | aaaaa |

| pseudoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com