Preparation method of mecury tungstate nanometer material

A technology of tungstic acid and tungsten source, which is applied in chemical instruments and methods, mercury compounds, tungsten compounds, etc., can solve the problems that there is no preparation method of mercury tungstate nanomaterials, difficult to control the shape of products, and high requirements for reaction temperature. Achieve the effect of avoiding product aggregation, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 0.002 moles of HgCl respectively 2 and Na 2 WO 4 , and then were dissolved in 20 ml of distilled water to make a concentration of 0.10 mol / L HgCl 2 and Na 2 WO 4 solution, and then divide it into two 100ml beaker containers.

[0029] (2) First fill the HgCl 2 The beaker of the solution was placed in the ultrasonic reactor. Under ultrasonic conditions, the same volume and concentration of Na prepared in step (1) 2 WO 4 The solution was slowly dropped into it at a speed of 0.04 ml / min, and ultrasonicated for 6 hours, then left to stand for 1 hour, and then centrifuged, and the precipitated products obtained by centrifugation were washed with distilled water and absolute ethanol alternately for 3 to 6 times. The product of the present invention can be obtained.

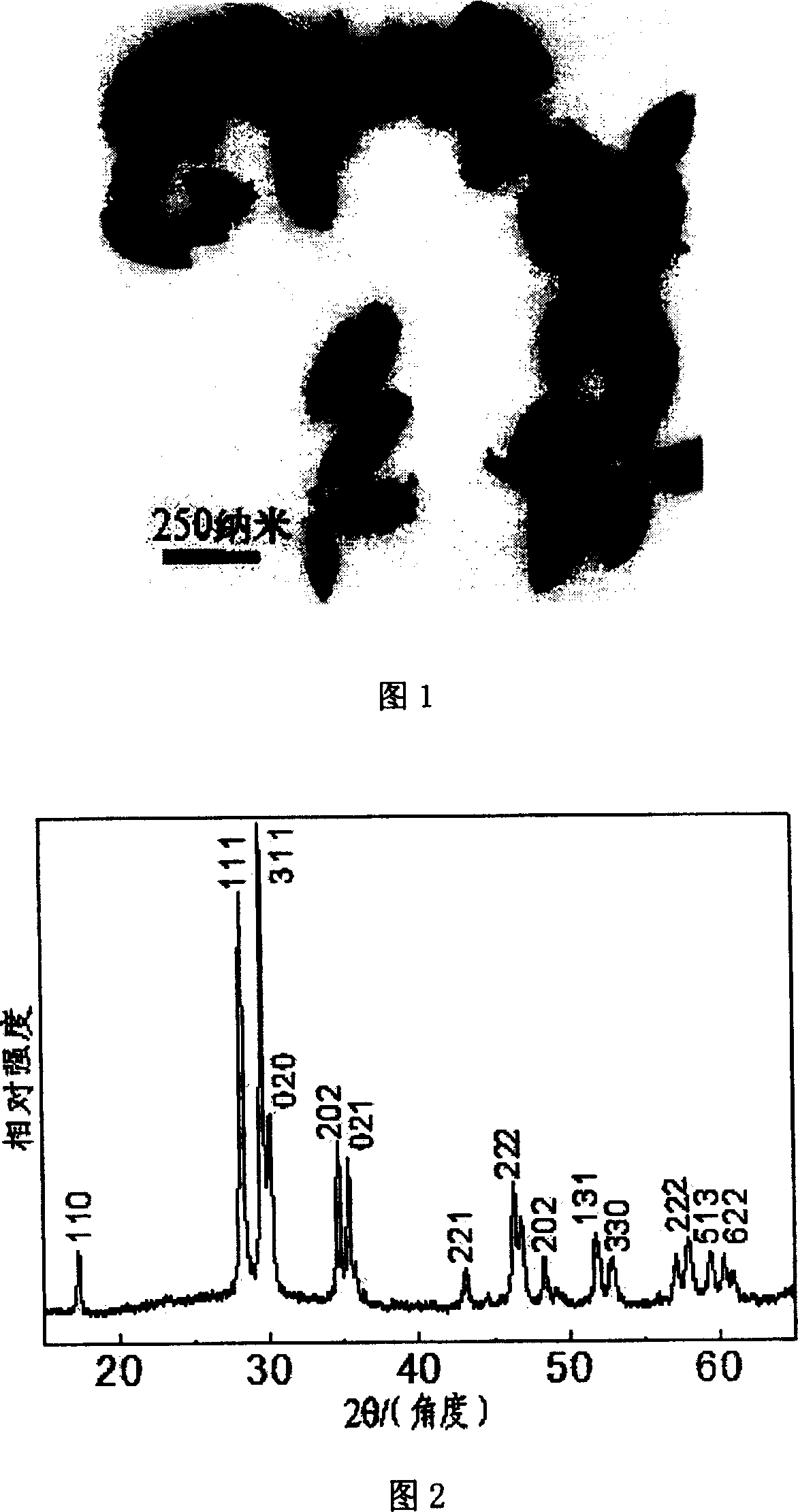

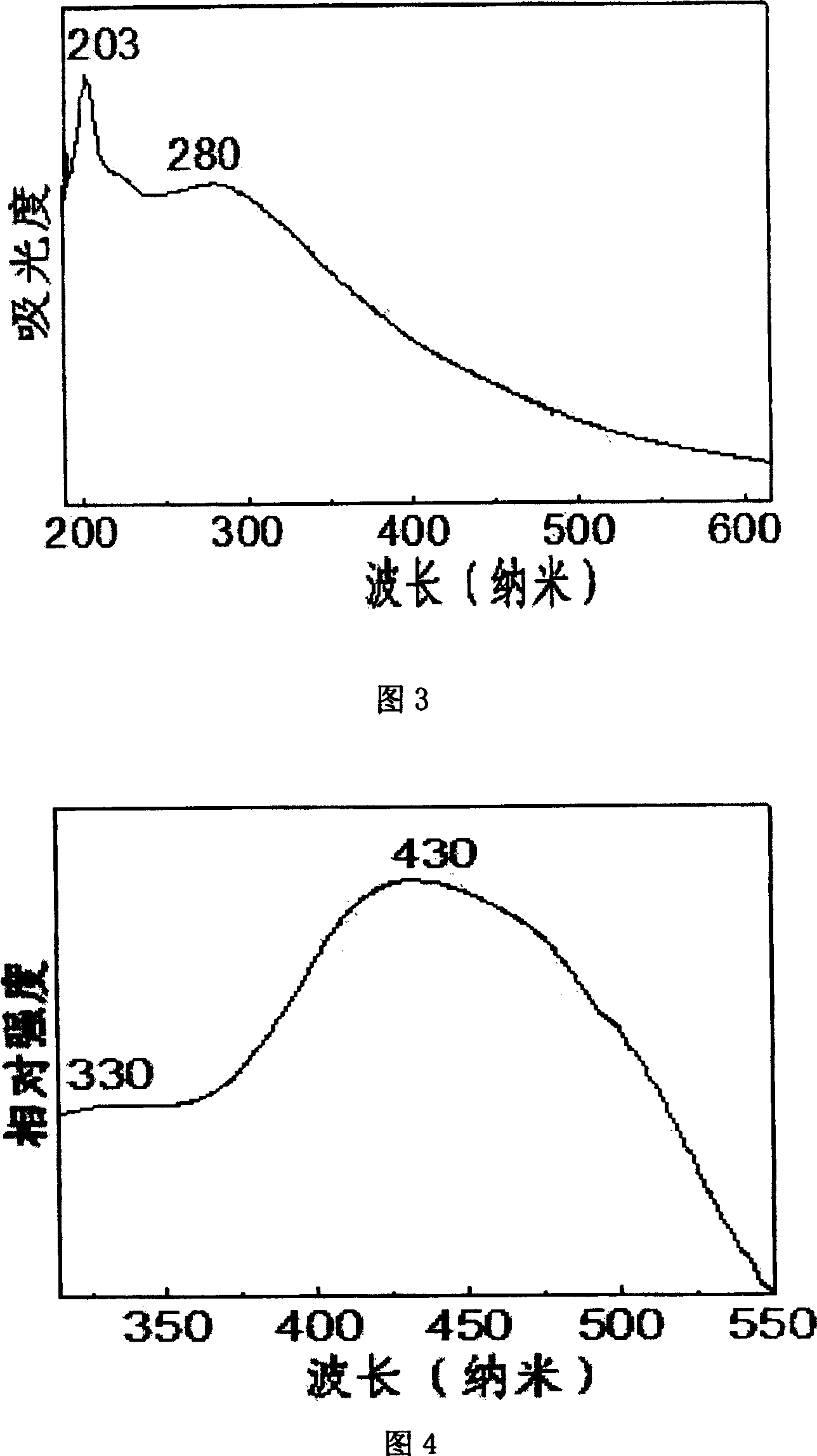

[0030] The product obtained in step (2) is stored in absolute ethanol, and the morphology and structure of the product are characterized by transmission electron microscope (TEM) and X-ray powde...

Embodiment 2

[0032] Weigh 0.006 moles of HgCl 2 and Na 2 WO 4 , and then dissolved in 20 ml of distilled water to make a concentration of 0.30 mol / L HgCl 2 and Na 2 WO 4 solution, and then divide it into two 100ml beaker containers. Other conditions and steps are exactly the same as in Example 1, and the obtained product is HgWO with a diameter of about 300 nanometers and a length of about 550 nanometers. 4 The crystal system of the quasi-nanometer spindle is the same as in Example 1. The product has high purity and good crystallinity. Compared with Example 1, the degree of blue shift of the fluorescence peak is smaller.

Embodiment 3

[0034] HgCl in step (2) 2 The solution was dropped into Na 2 WO 4 solution, and the standing time was 4 hours, other conditions and steps were exactly the same as in Example 1, and the product obtained was HgWO with a diameter of about 250 nanometers and a length of about 380 nanometers. 4 The crystal system of the quasi-nano short rod is the same as that of Example 1. The product has high purity, good crystallinity and optical properties. Compared with Example 1, the degree of blue shift of the fluorescence peak is smaller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com