Adsorbing precipitant of anionic dye, its synthetic process and uses

An anionic dye, adsorption and precipitation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high treatment cost, low decolorization rate, and inability to remove dyes, etc., and achieve fast precipitation, simple operation, and ideal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail.

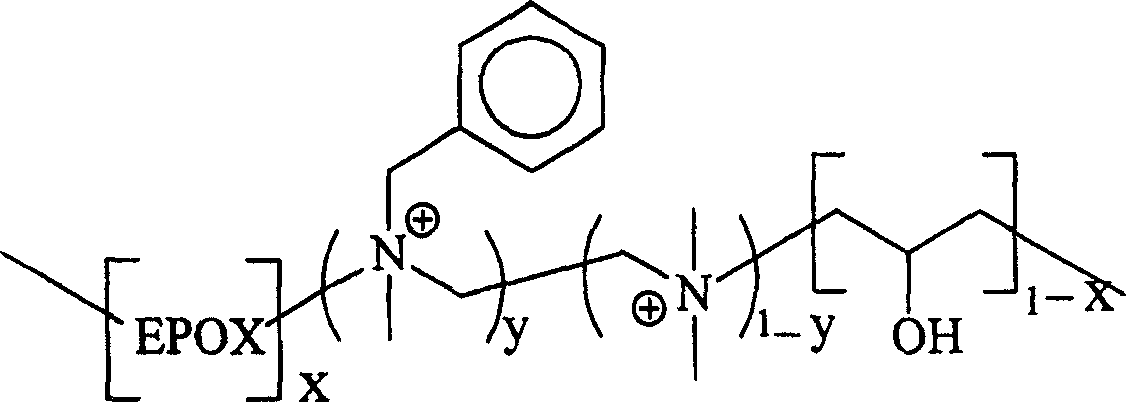

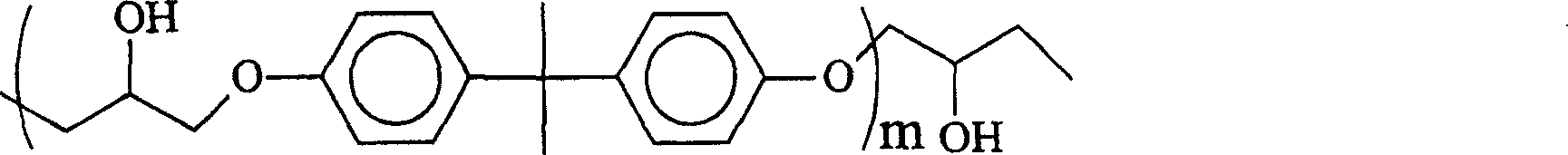

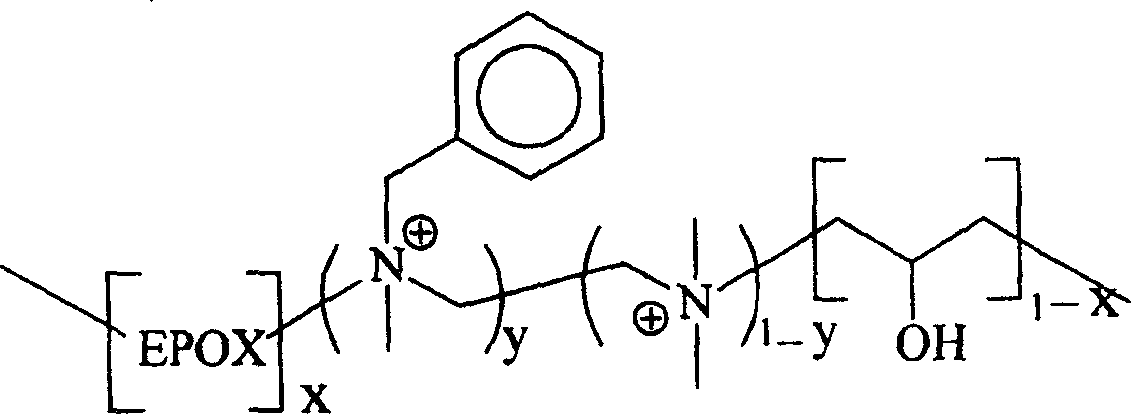

[0021] Add different weights of epoxy resin (brand E-44) and ethylenediamine (dissolved in 6ml of methanol) in a four-neck flask equipped with a stirrer, reflux condenser, dropping funnel and thermometer respectively according to Table 1. After mixing evenly (a large amount of heat is released, cooling with cold water is required), react at 70-80°C for 1 hour. After the reaction between the resin and ethylenediamine is complete, add different amounts of epichlorohydrin dropwise according to Table 1. After the drop is completed within 0.5 hours, keep the temperature at 100°C for 0.5 hours to ensure sufficient polymerization, and finally obtain high-temperature viscous low-temperature Cured polyamine resin. The solubility of polyamine resin is related to the composition of the reactants. Its solubility in water decreases with the increase of the amount of epoxy resin added. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com