Method for preparing liquid boron fertilizer with surface active function

A surface active, liquid technology, applied in the field of liquid boron fertilizer, can solve the problems of leaf surface spreading, adhesion and rain erosion resistance, limited effective boron content in aqueous solution, low utilization rate of boron nutrient, etc., to achieve excellent Rain erosion resistance, improved fertilizer use efficiency and absorption speed, good spread and adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix boric acid, ethylenediamine, and water in a molar ratio of 4:1:2, stir evenly, heat to 100±5°C to dissolve, reflux for 2 hours, cool to 90±5°C while stirring While adding 0.5 mole of glycerin, keep the temperature, reflux reaction for 1 hour, stop heating, cool to room temperature to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

Embodiment 2

[0025] Mix boric acid, diboron trioxide, diethylenetriamine, ethylenediamine, and water in a molar ratio of 3:2:2:0.1:5, stir evenly, and dissolve under the condition of heating to 110±5°C. Reflux for 2 hours, cool to 90±5°C, add 0.5 mole of sodium dodecylsulfonate while stirring, keep the temperature, reflux for 1.5 hours, stop heating, cool to room temperature to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

Embodiment 3

[0027] Mix boric acid, borax, diboron trioxide, diethanolamine, glycerol, and water in a molar ratio of 2:2:2:1:0.5:4, stir evenly, and heat to 110±5°C to dissolve. Reflux for 3 hours, cool to 90±5°C, add 0.5 mole ammonium dodecylbenzenesulfonate while stirring, keep the temperature, reflux for 1.5 hours, stop heating, and cool to room temperature to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

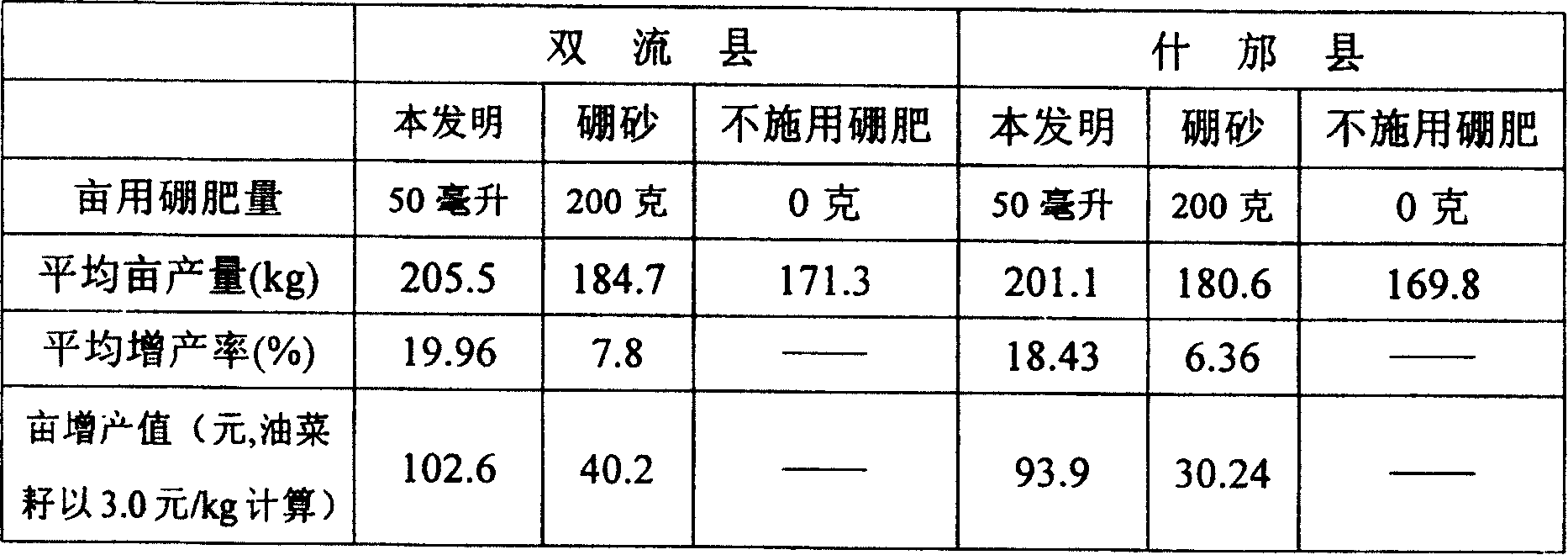

[0028] Table 1 The present invention is used for the test situation of main boron crops such as rapeseed

[0029] (This experiment was conducted in Shuangliu County and Shifang County, Sichuan Province)

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com