Load type nano-au catalyst and the preparing method

A catalyst, supported technology, applied in catalyst carrier, oxidation reaction preparation, carbon-based compound preparation, etc., can solve the problems of high reaction temperature, pipeline blockage, short catalyst life, etc., achieve low peroxide content, easy to recycle , the effect of high ketone alcohol selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

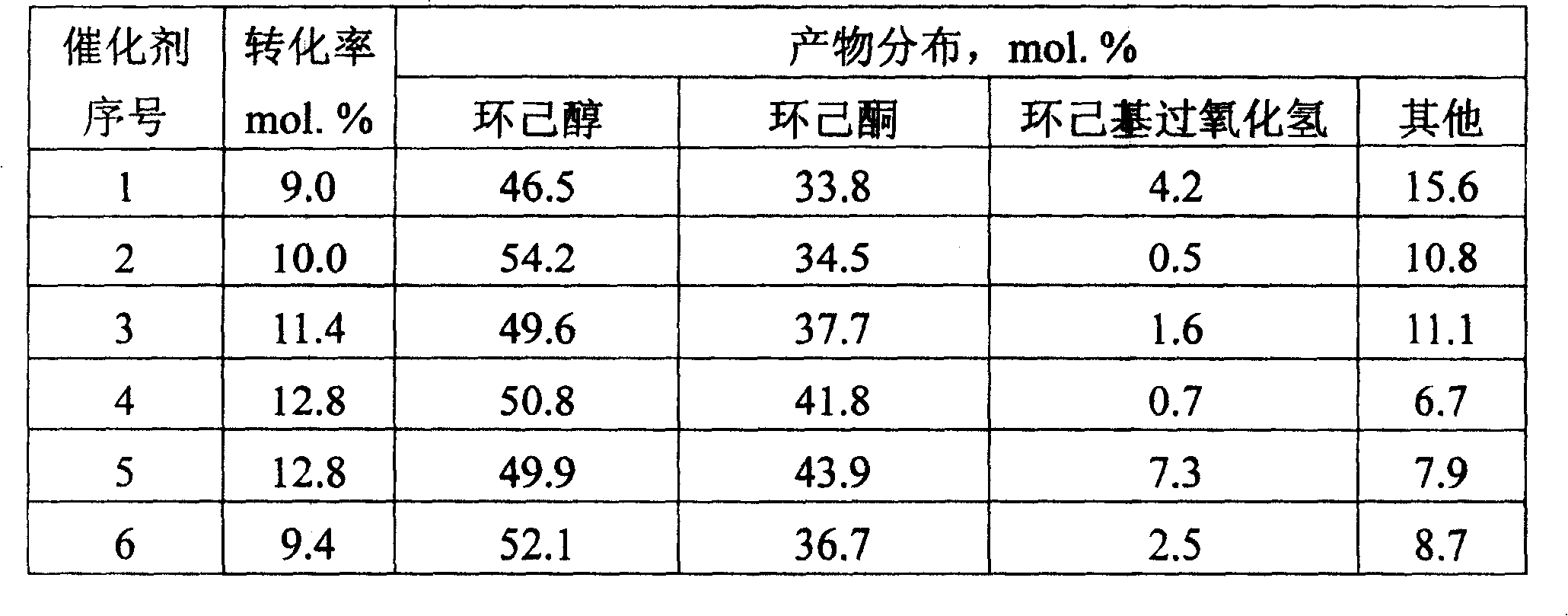

Examples

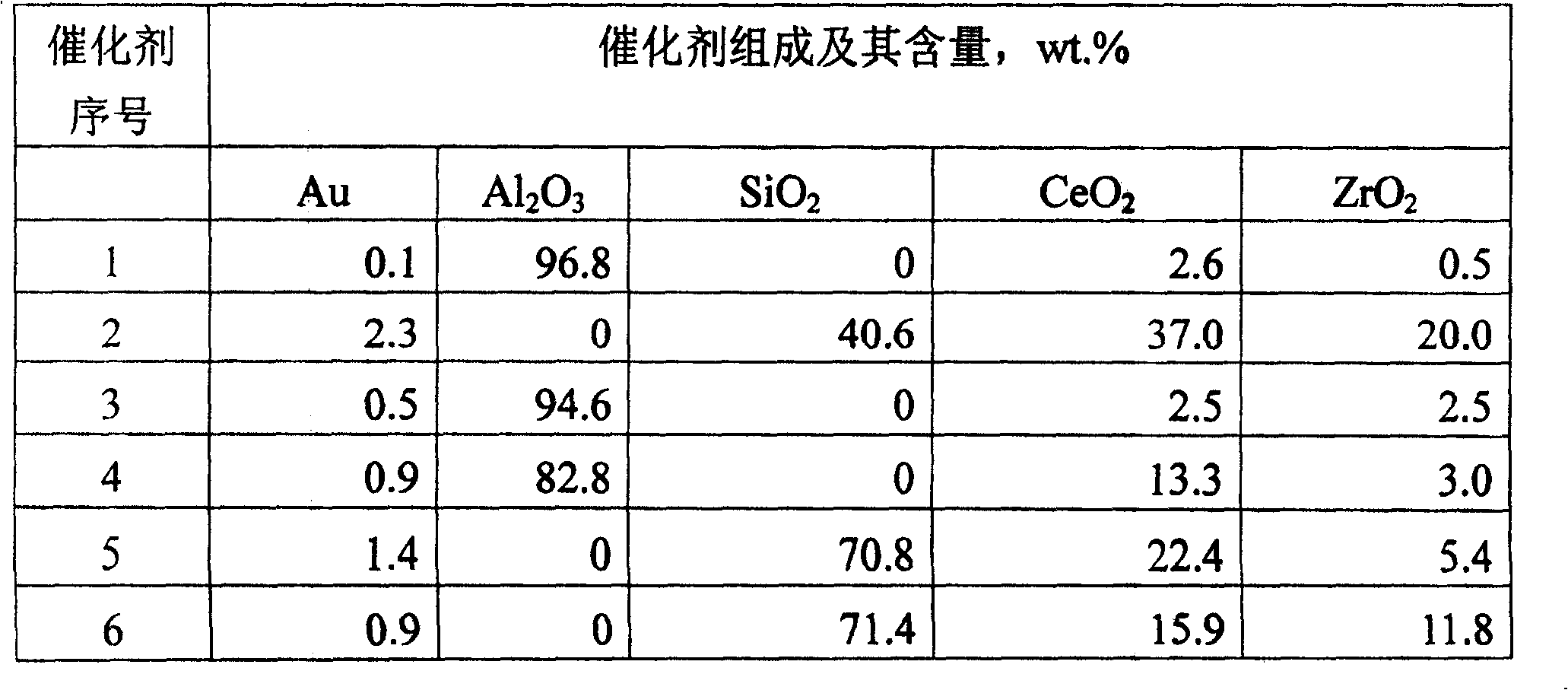

Embodiment 1

[0018] 1) 8.7 grams of Al 2 o 3 Containing 0.58 g Ce(NO 3 ) 3 ·6H 2 O and 0.14 g Zr(NO 3 ) 4 ·5H 2 Immerse an equal volume of O in an aqueous solution at room temperature for 12 hours. After the impregnation is completed, dry at 60°C for 2 hours, and calcinate at 300°C for 1 hour to obtain a catalyst carrier;

[0019] 2) The obtained catalyst support was added to a mixture containing 0.02 gram of HAuCl 4 4H 2 In 500 ml of aqueous solution of O, adjust the pH value to 4.0 with NaOH solution, stir and impregnate at 30 ° C for 1 h; filter or centrifuge the solid product obtained by washing with 30 ml of 1M ammonia water, then wash with water until neutral, and dry at 60 ° C for 2 h , and calcined at 300° C. for 1 h to obtain catalyst 1 .

Embodiment 2

[0021] 1) 8.7 g of SiO 2 Containing 19.8 grams of Ce (NO 3 ) 3 ·6H 2 O and 14.8 g Zr(NO 3 ) 4 ·5H 2 The aqueous solution of O was impregnated in equal volume at room temperature for 24 hours. After the impregnation was completed, it was dried at 200°C for 6 hours and calcined at 700°C for 6 hours to obtain a catalyst carrier;

[0022] 2) The obtained catalyst support was added to a mixture containing 1.05 g of HAuCl 4 4H 2 In 500 ml of aqueous solution of O, adjust the pH value to 6.0 with NaOH solution, stir and impregnate at 90 ° C for 2 h; filter or centrifuge the solid product obtained by washing with 100 ml of 4M ammonia water, then wash with water until neutral, and dry at 200 ° C for 6 h , Calcined at 700°C for 6h to obtain catalyst 2.

Embodiment 3

[0024] 1) 8.7 grams of Al 2 o 3 Containing 0.6 g Ce(NO 3 ) 3 ·6H 2 O and 0.8 g Zr(NO 3 ) 4 ·5H 2 The aqueous solution of O was impregnated with equal volume at room temperature for 12 hours, after the impregnation was completed, dried at 80°C for 4h, and calcined at 400°C for 6h to obtain the catalyst carrier;

[0025] 2) The obtained catalyst carrier was added to a mixture containing 0.1 gram of HAuCl 4 4H 2 O in 500 ml of aqueous solution, the pH value was adjusted to 4.0 with NaOH solution. The obtained catalyst carrier was added to the above solution, stirred and reacted at 60°C for 2h, filtered, and the solid product was washed with 30ml of 1M ammonia water until neutral, dried at 80°C for 4h, and calcined at 600°C for 1h to obtain Catalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com