Stabilizer for use in sodium chlorite degumming and bleaching of flax and its preparation method and application

A technology of flax sodium chlorite and sodium chlorite, which is applied in the direction of bleaching products, textiles and papermaking, and producing bast fibers by chemical methods, and can solve problems such as complexity, long process, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

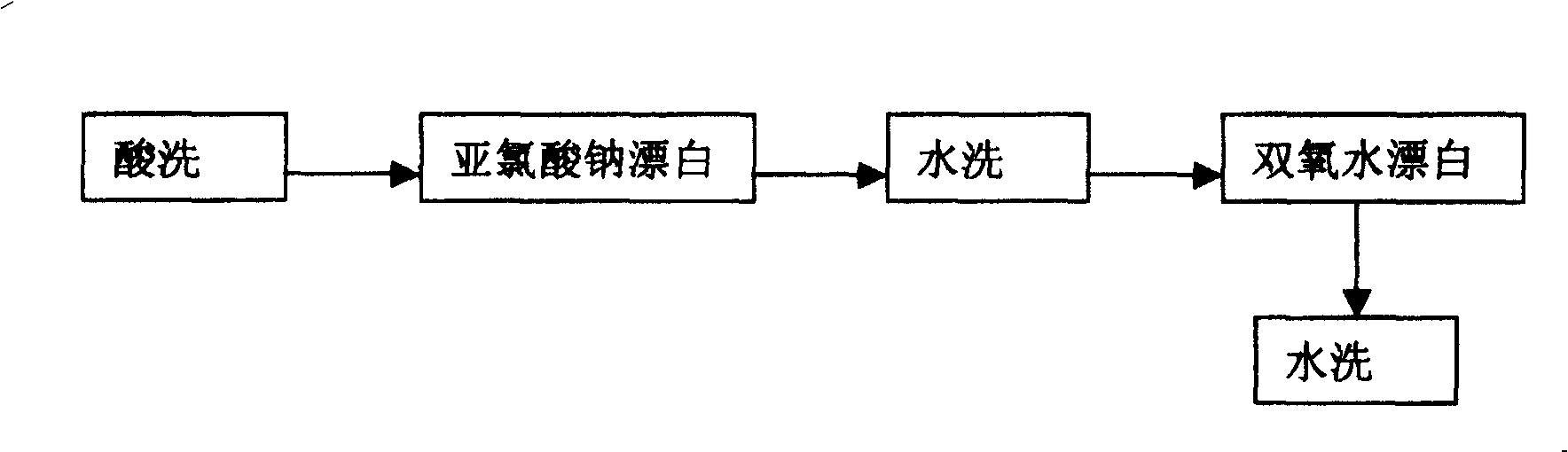

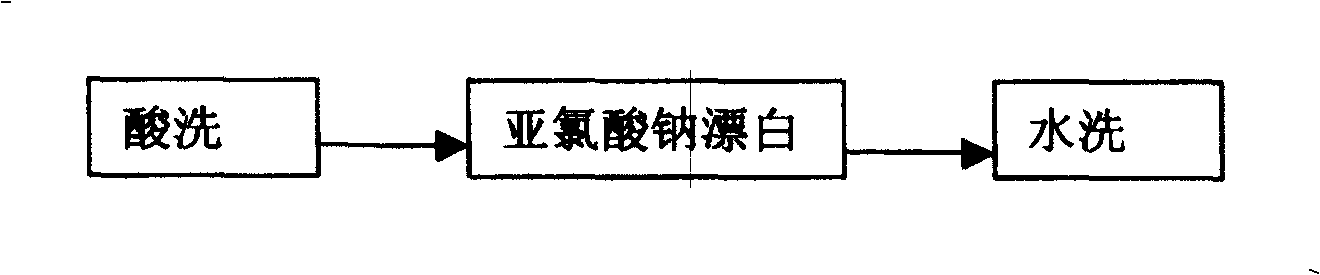

[0025] Please see attached figure 2 , the technical process of flax roving degumming and bleaching in this embodiment is as follows figure 2 shown.

[0026] The yarn to be degummed and bleached adopts flax roving (the roving made by Yulu hemp, and the roving count is 18Nm) 200g. Soak flax roving in sulfuric acid (sulfuric acid 10g / L, room temperature, 20 minutes) → wash with water, then wash with sodium chlorite solution (bath ratio 1:10, sodium chlorite dosage 15g / L, pH=3.5, activator acetic acid 3g / L, stabilizer 3g / L, temperature 95°C) for 40 minutes, washed with water after treatment, and dried to complete the degumming and bleaching process of flax roving. Wherein, the composition (mass percentage) of the stabilizer is: 3% of hexamethyleneamine, 1% of hydrazine sulfate, 2% of triethanolamine, 1% of ammonium persulfate and water.

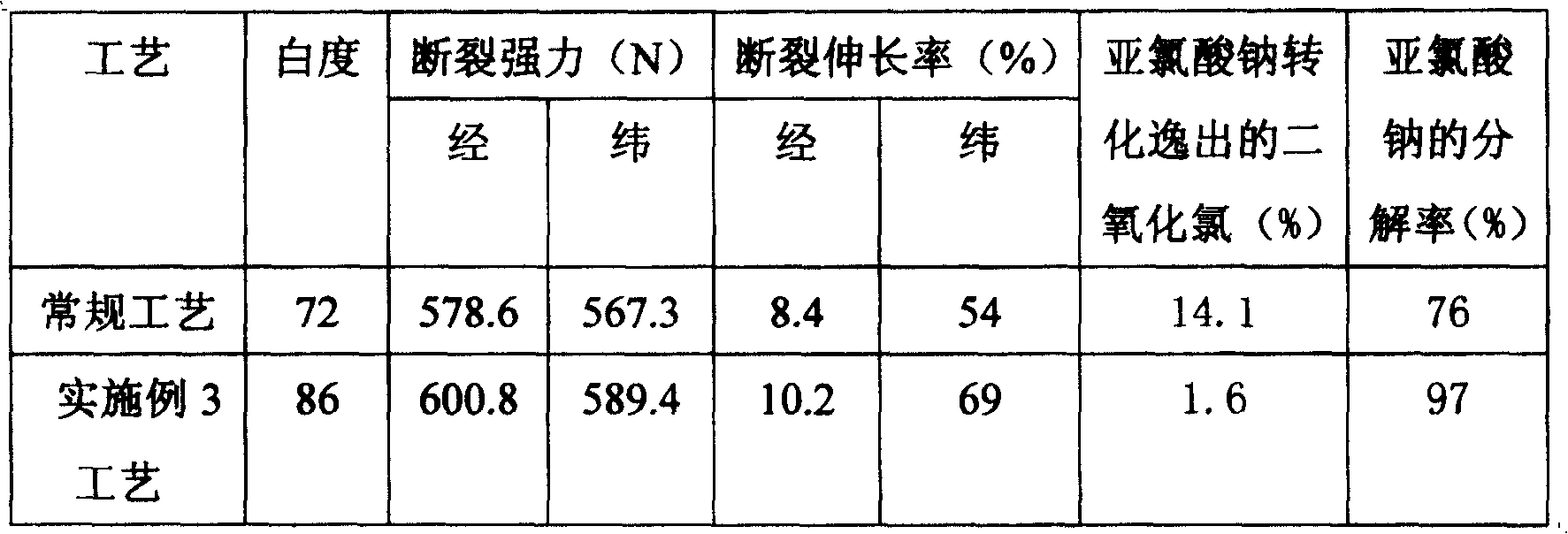

[0027] Table 1 is the main performance index comparison between degumming and bleaching of flax roving in Example 1 and conventional degum...

Embodiment 2

[0032] Please see attached figure 2 , the technical process of flax roving degumming and bleaching in this embodiment is as follows figure 2 shown.

[0033] The roving to be degummed and bleached adopts flax roving (the roving spun by Yulu hemp, and the roving count is 20Nm) 200g. Soak flax roving in sulfuric acid (sulfuric acid 8g / L, room temperature, 30 minutes) → wash with water, then use sodium chlorite solution (bath ratio 1:15, sodium chlorite dosage 20g / L, pH=4, activator acetic acid 5g / L, stabilizer 5g / L, temperature 100°C) for 30 minutes, washed with water after treatment, and dried to complete the degumming and bleaching process of flax roving. Wherein, the composition (mass percentage) of the stabilizer is: 5% of hexamethyleneamine, 3% of hydrazine sulfate, 6% of triethanolamine, 3% of ammonium persulfate and water.

[0034] Other conditions and methods are the same as in Example 1.

[0035] Table 2 is the main performance index comparison between degumming a...

Embodiment 3

[0040] Please see attached figure 2 , the present embodiment is to the technological process of flax fabric bleaching as figure 2 shown.

[0041] The fabric to be bleached adopts linen fabric (plain weave, 220g / m 2 , 150×158 pieces / dm) 30×40cm piece. Squeeze the linen fabric with acid (sulfuric acid 15g / L, room temperature) → stack (room temperature, 20 minutes) → wash with water, then use sodium chlorite solution (sodium chlorite dosage 20g / L, pH=4, activator acetic acid 6g / L, stabilizer 8g / L, temperature 95°C) for 30 minutes, washed with water after treatment, and dried to complete the bleaching process of linen fabric. Bleached linen was dyed using the following recipe. Wherein, the composition (mass percentage) of the stabilizer is: 6% of hexamethyleneamine, 4% of hydrazine sulfate, 5% of triethanolamine, 4% of ammonium persulfate and water.

[0042] Reactive dye B-4RFN 1%, Nacl 12~25g / L, leveling agent 5~10g / L, dyeing temperature 85°C, dyeing time 40 minutes; soap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com