Titania powder for honeycomb waste gas treating catalyst, and waste gas treating catalyst

A technology for waste gas treatment and titanium dioxide, which is used in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the difficulties of honeycomb structures, catalyst reduction, poor formability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1

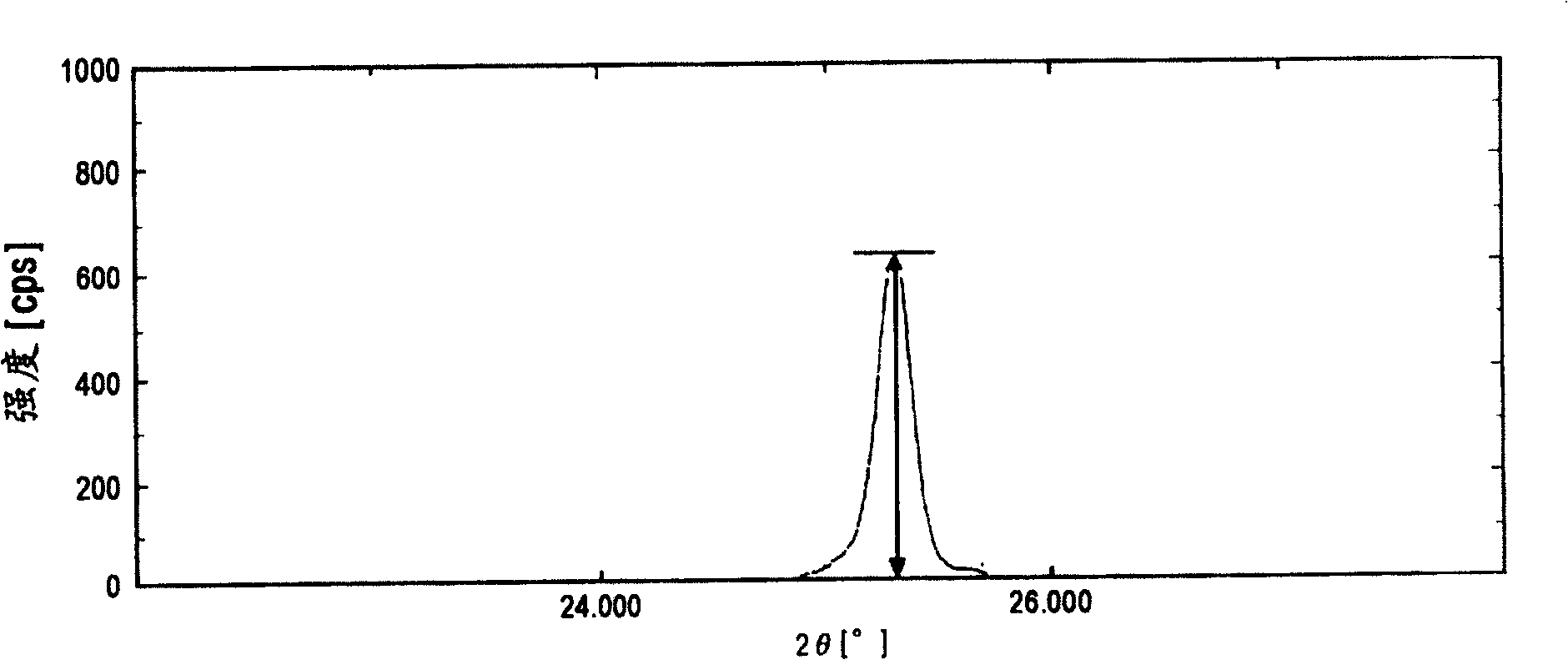

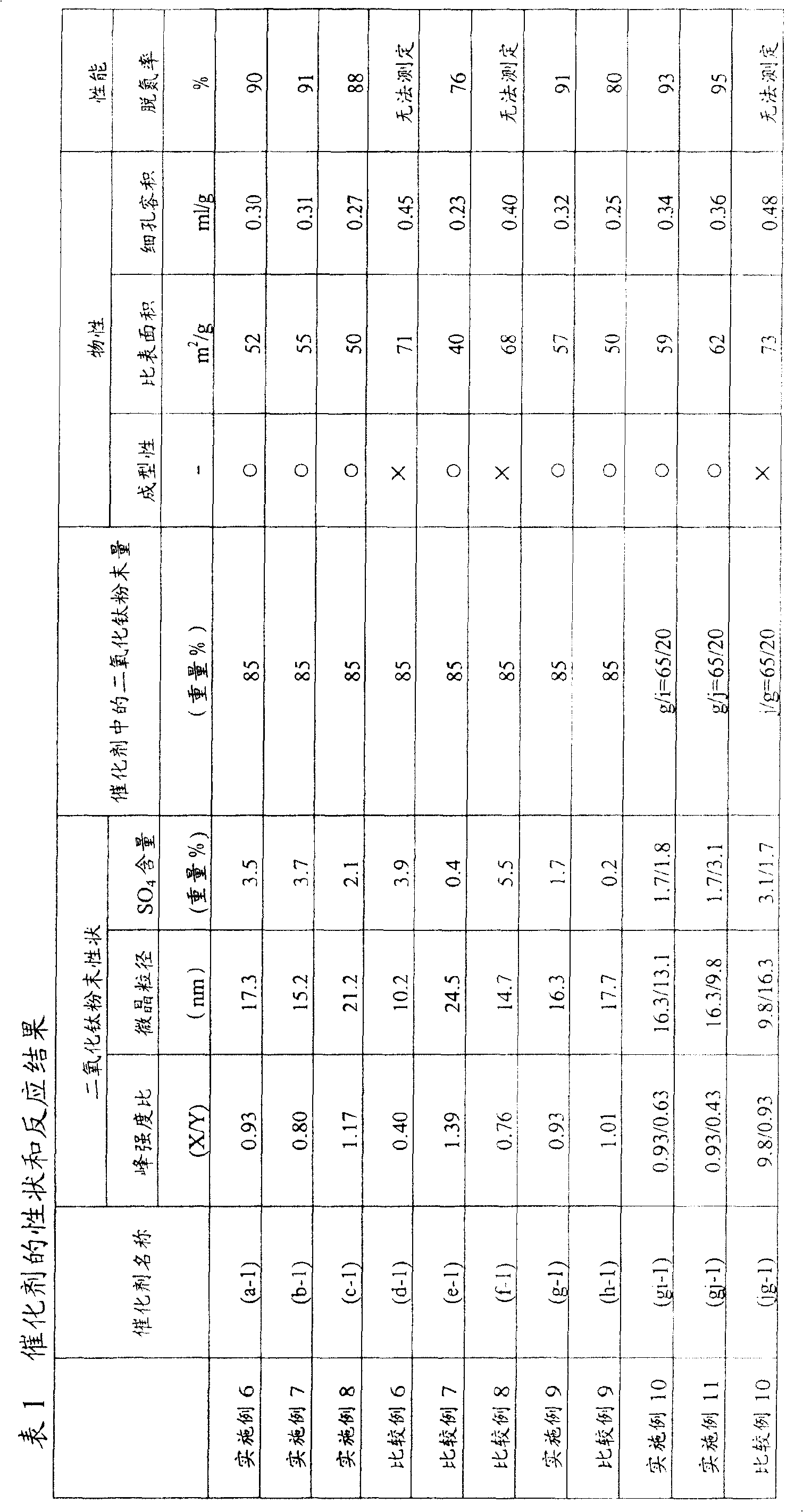

[0060] The titanium sulfate solution prepared by sulfuric acid titanium dioxide manufacturing process is thermally hydrolyzed to obtain metatitanic acid slurry. Take out 25.0 kg of the metatitanic acid slurry as titanium dioxide, put it into a stirred tank with a reflux device, add 30.5 kg of 15% by weight ammonia water therein, so that the pH value is adjusted to 9.5, and then fully stir at 95 ° C 1 hour, while heating to ripen. Then cool, take out the slurry, filter, dehydrate, wash to obtain SO 4 4.1wt% (based on dry weight), Na 2 O is 0.03wt% (based on dry weight) of the washed filter cake. This washed cake was dried at 110° C. for 20 hours, and then baked at 509° C. for 5 hours to obtain titanium dioxide powder. This titanium dioxide powder was further pulverized to prepare a titanium dioxide powder (a) for a honeycomb exhaust gas treatment catalyst composed of titanium dioxide. Using a powder X-ray diffraction device (manufactured by Rigaku Cor...

Embodiment 2

[0062] Example 2

[0063] The washed filter cake prepared in the same manner as in Example 1 was dried at 110° C. for 20 hours, and then calcined at 459° C. for 5 hours to obtain a honeycomb-shaped titanium dioxide powder for exhaust gas treatment catalyst composed of titanium dioxide. This titanium dioxide powder was pulverized to prepare a titanium dioxide powder (b) for a honeycomb exhaust gas treatment catalyst composed of titanium dioxide. The peak height X of the (101) plane of the anatase-type titanium dioxide crystal (101) measured by the powder X-ray diffraction method of the titanium dioxide powder (b) for the honeycomb exhaust gas treatment catalyst composed of titanium dioxide is 121 mm, compared with the peak intensity of the reference sample The ratio (X / Y) was 0.80.

[0064] In addition, in this titanium dioxide powder (b), the crystallite particle size calculated by Scherrer's formula in the anatase type crystal (101) plane is 15.2 nm, and the sulfate radic...

Embodiment 3

[0065] Example 3

[0066] The washed filter cake prepared in the same manner as in Example 1 was dried at 110° C. for 20 hours, and then calcined at 601° C. for 5 hours to obtain a honeycomb-shaped titanium dioxide powder for exhaust gas treatment catalyst composed of titanium dioxide. This titanium dioxide powder was pulverized to prepare a titanium dioxide powder (c) for a honeycomb exhaust gas treatment catalyst composed of titanium dioxide. The peak height X of the (101) plane of the anatase-type titanium dioxide crystal (101) measured by the powder X-ray diffraction method of the titanium dioxide powder (c) for the honeycomb exhaust gas treatment catalyst composed of titanium dioxide is 177 mm, compared with the peak intensity of the reference sample The ratio (X / Y) was 1.17.

[0067] In addition, in this titanium dioxide powder (c), the crystallite particle size calculated by Scherrer's formula in the anatase type crystal (101) plane is 21.2 nm, and the sulfate radic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com