Minute pattern photoetching method

A lithography pattern and micro technology, which is applied to microlithography exposure equipment, photolithography process exposure devices, electrical components, etc., can solve the problems of high price, high cost, and increase the complexity of the production process, so as to improve production capacity and simplify the production process. The effect of mass production process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

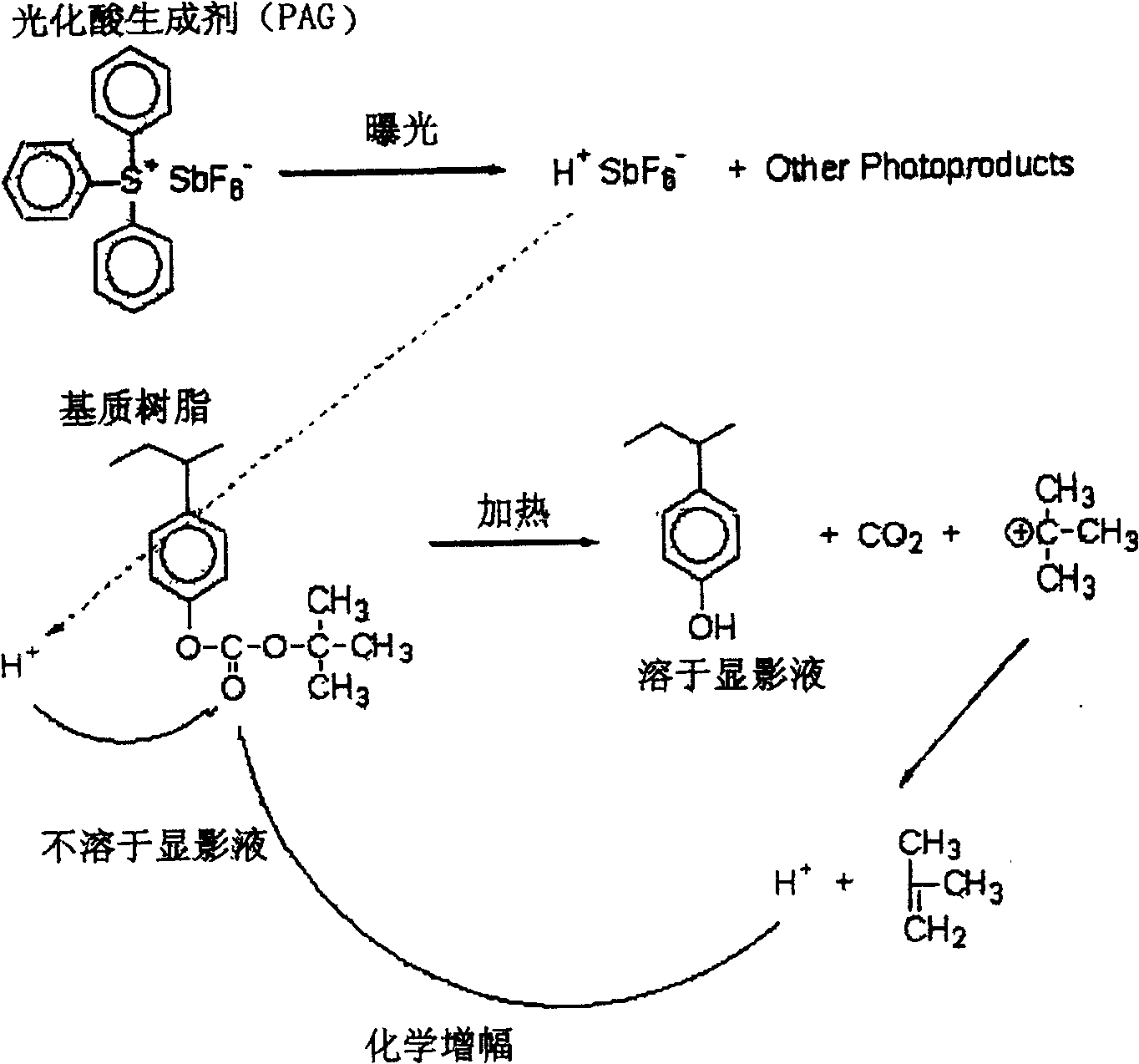

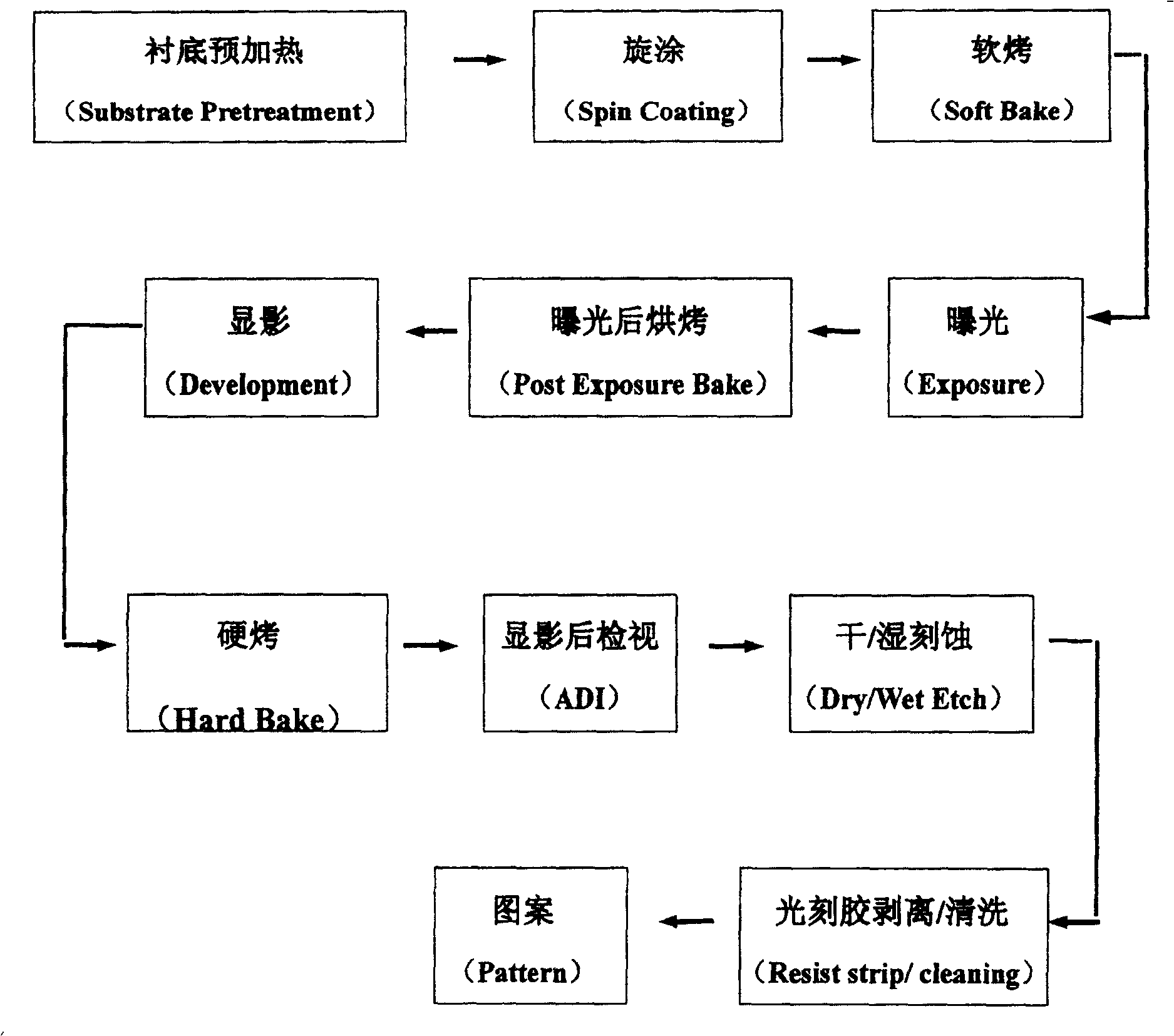

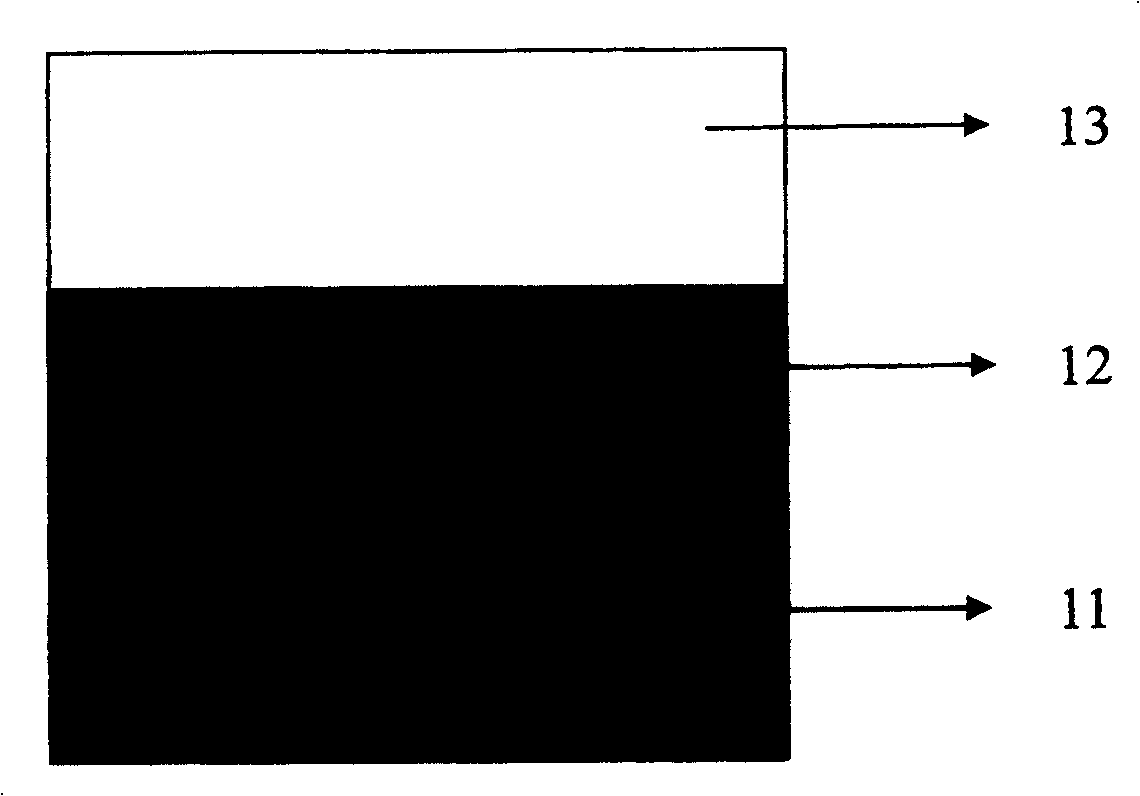

[0032] The invention provides a method for fine photolithographic patterns, which mainly includes coating a layer of bottom layer resin on the entire etched substrate layer surface; coating a layer of photoresist on the upper surface of the bottom layer resin layer; The layer is exposed to the required pattern, and baked after exposure; the photoresist layer and the underlying resin layer are developed in the developer, and a photoresist pattern is formed on the photoresist and the underlying resin layer; the photoresist and the underlying resin layer are used as the etching The etch stop layer is selectively etched to transfer the pattern onto the substrate.

[0033] According to the method of the present invention, the substrate material can be any thin film material that is etched or ion-implanted to transfer a pattern or form a desired pattern in a specific area, which is generally used in semiconductor manufacturing such as DRAM.

[0034] According to the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com