Method for preparing white fungus beverage

A technology for white fungus and beverages, which is applied in the directions of food preparation, medical preparations containing active ingredients, liquid materials, etc., can solve the problems such as the refreshing and smooth taste of white fungus cannot be reflected, and the shelf life of products is difficult to control, and achieves the problem of avoiding secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

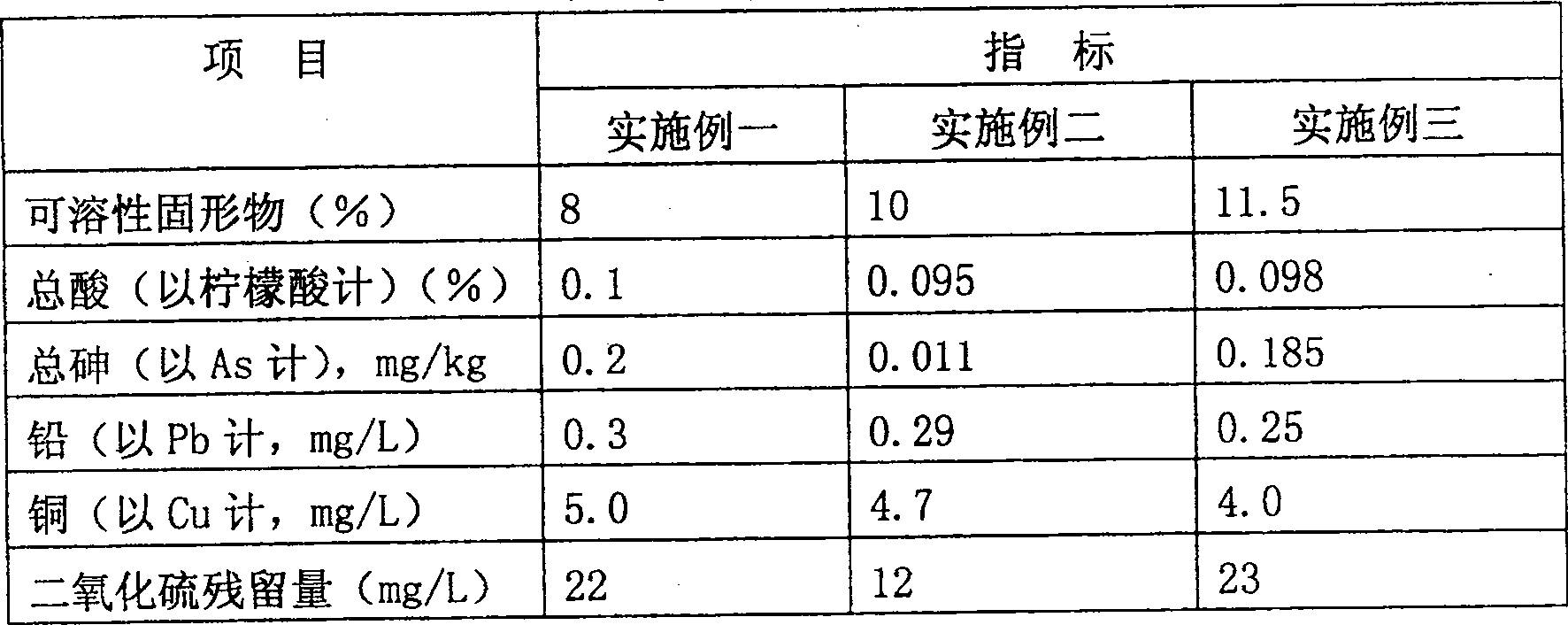

Examples

Embodiment 1

[0024] 1. Soak white fungus for 1 hour. After manual selection, pick out white fungus feet, mildewed, rotten white fungus, sawdust and other foreign matter, and rinse with water for several times for later use; remove the core of red dates, wash and chop them for later use, and put lotus seeds, Lycium barbarum is washed, dried and crushed for later use;

[0025] 2 Break the rinsed white fungus in a refiner to make a slurry with a particle size of 0.5mm;

[0026] 3 Cook the raw material in a container with a temperature of 100°C and a pressure of 0.05MPa for 4 hours;

[0027] 4 Mix 8 parts of tremella paste, 85 parts of water, 5 parts of rock sugar, 0.05 parts of citric acid, 0.3 parts of sodium carboxymethyl cellulose, 0.03 parts of sucralose, 2 parts of red dates, 2 parts of lotus seeds, and 2 parts of wolfberry, and stir Uniform;

[0028] 5 The prepared material is sterilized at a temperature of 140°C for 3 seconds, and filled at a temperature of 95°C while it is still hot...

Embodiment 2

[0030] 1. Soak the white fungus for 1.5 hours. After manual selection, pick out the white fungus feet, mildewed, rotten white fungus, sawdust and other foreign matter, and rinse it with clean water several times for later use; remove the core of the red dates, wash and chop them for later use, and put the lotus seeds, Lycium barbarum is washed, dried and crushed for later use;

[0031] 2 Break the rinsed white fungus in a refiner to make a slurry with a particle size of 1.5 mm;

[0032] 3 Cook the raw slurry in a container with a temperature of 115°C and a pressure of 0.08MPa for 3 hours;

[0033] 4 Mix 12 parts of white fungus slurry, 80 parts of water, 6 parts of rock sugar, 0.1 part of citric acid, 0.1 part of sodium carboxymethyl cellulose, 0.01 part of sucralose, 1 part of red dates, 1 part of lotus seeds, and 1 part of wolfberry, and stir Uniform;

[0034] 5 The prepared materials are subjected to instantaneous high-temperature sterilization at a temperature of 135°C f...

Embodiment 3

[0036] 1. Soak the white fungus for 2 hours. After manual selection, select the white fungus feet, mildewed, rotten white fungus, sawdust and other foreign objects, and rinse it with clean water several times for later use; remove the core of the red dates, wash and chop them for later use, and put the lotus seeds, Lycium barbarum is washed, dried and crushed for later use;

[0037] 2 Break the rinsed white fungus in a refiner to make a slurry with a particle size of 3mm;

[0038] 3 Cook the raw slurry in a container with a temperature of 121°C and a pressure of 0.1MPa for 2 hours;

[0039] 4 Mix 5 parts of white fungus slurry, 90 parts of water, 3 parts of rock sugar, 0.08 parts of citric acid, 0.5 parts of sodium carboxymethyl cellulose, 0.05 parts of sucralose, 3 parts of red dates, 3 parts of lotus seeds, and 3 parts of wolfberry, and stir Uniform;

[0040] 5 The prepared materials are subjected to instantaneous high-temperature sterilization at a temperature of 130°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com