Method of preparing isotropic carbon material and prepared carbon material

A technology for isotropic carbon and mesophase carbon microspheres is applied in the field of high-strength, high-density isotropic fine-structure carbon materials, which can solve the problems of low product yield and easy cracking of products, and achieve excellent performance. , The effect of reducing process links and production cycle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

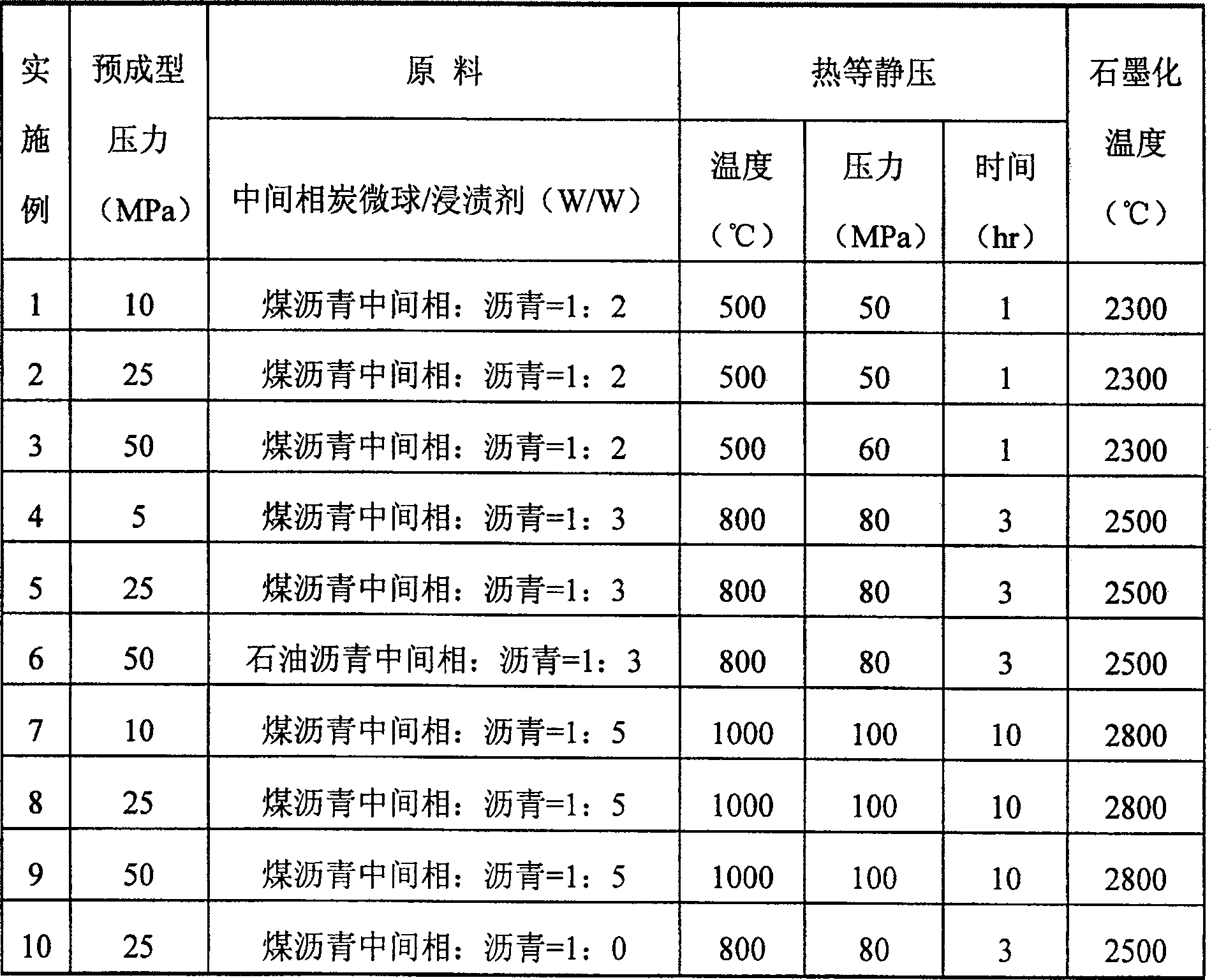

[0021] The relevant raw materials and their amounts in each embodiment, as well as the relevant process parameters of preforming, hot isostatic pressing and graphitization are shown in Table 1.

[0022] Table 1

[0023]

[0024] The following takes Example 5 as an example to specifically illustrate the preparation process of the present invention: ① Using self-baking mesocarbon microsphere powder (particle size 5-20μm) as raw material, pre-molding in a molding machine with a molding pressure of 25MPa; ② Successively Put 1 part (by weight, the same below) of carbon block green body and 3 parts of pitch impregnating agent into a hot isostatic press, using argon gas medium, heating and pressurizing, and maintaining temperature at 800℃ calcination temperature and 80MPa pressure 3 hours, then cool down naturally; ③The carbonized carbon block is graphitized at 2500°C in a graphitization furnace. The properties of the isotropic carbon materials are shown in Table 2.

[0025] Among them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com