Production of hydrogen for combining mineralize refuse, swill waste and sludge

A technology for mineralizing garbage and sludge, which is applied in waste fuel, climate change adaptation, bio-organic part treatment, etc. It can solve the problems of large initial investment, long fermentation cycle, unstable operation, etc., and achieves low infrastructure cost and hydrogen production. The effect of high volume and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

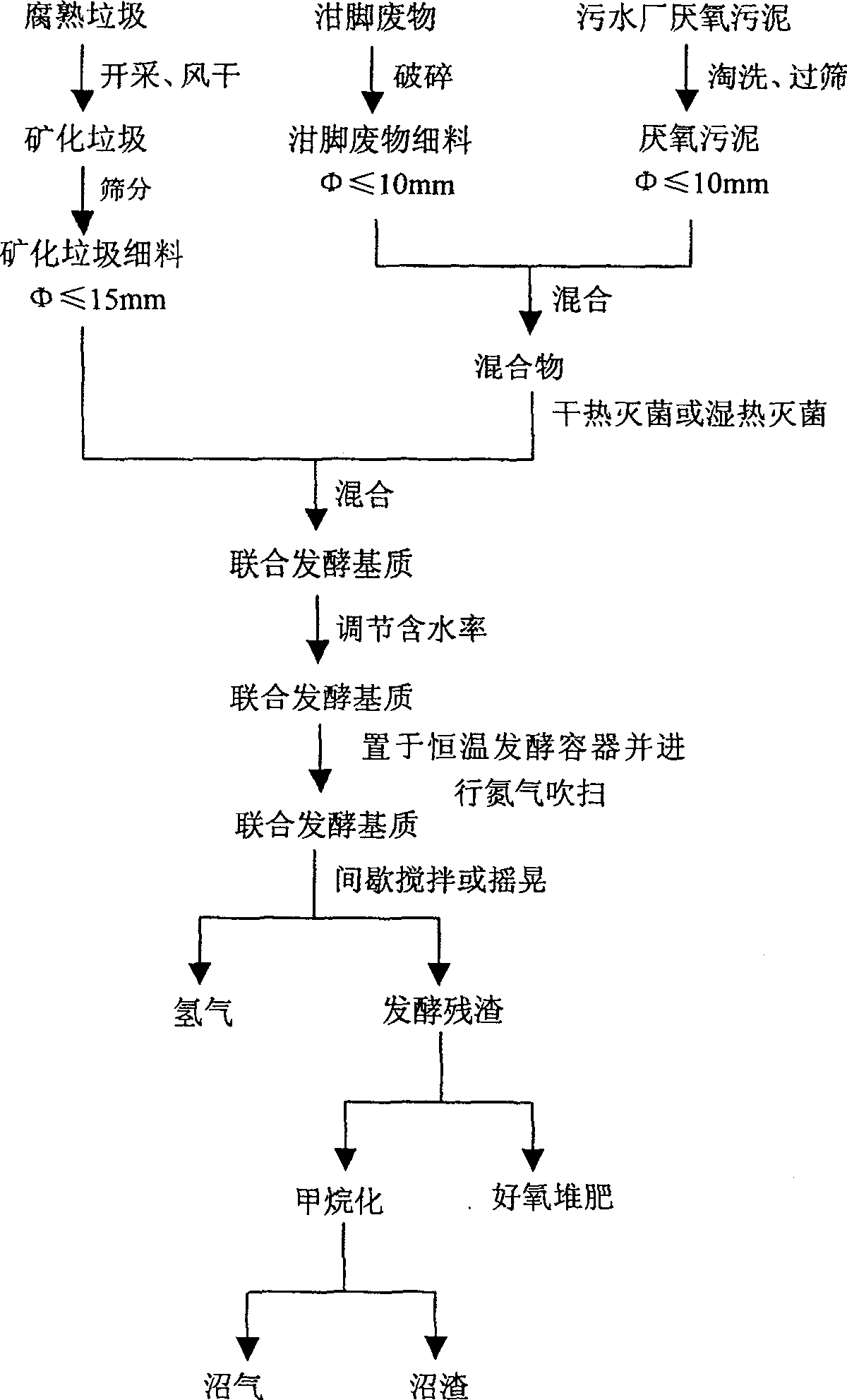

Method used

Image

Examples

Embodiment 1

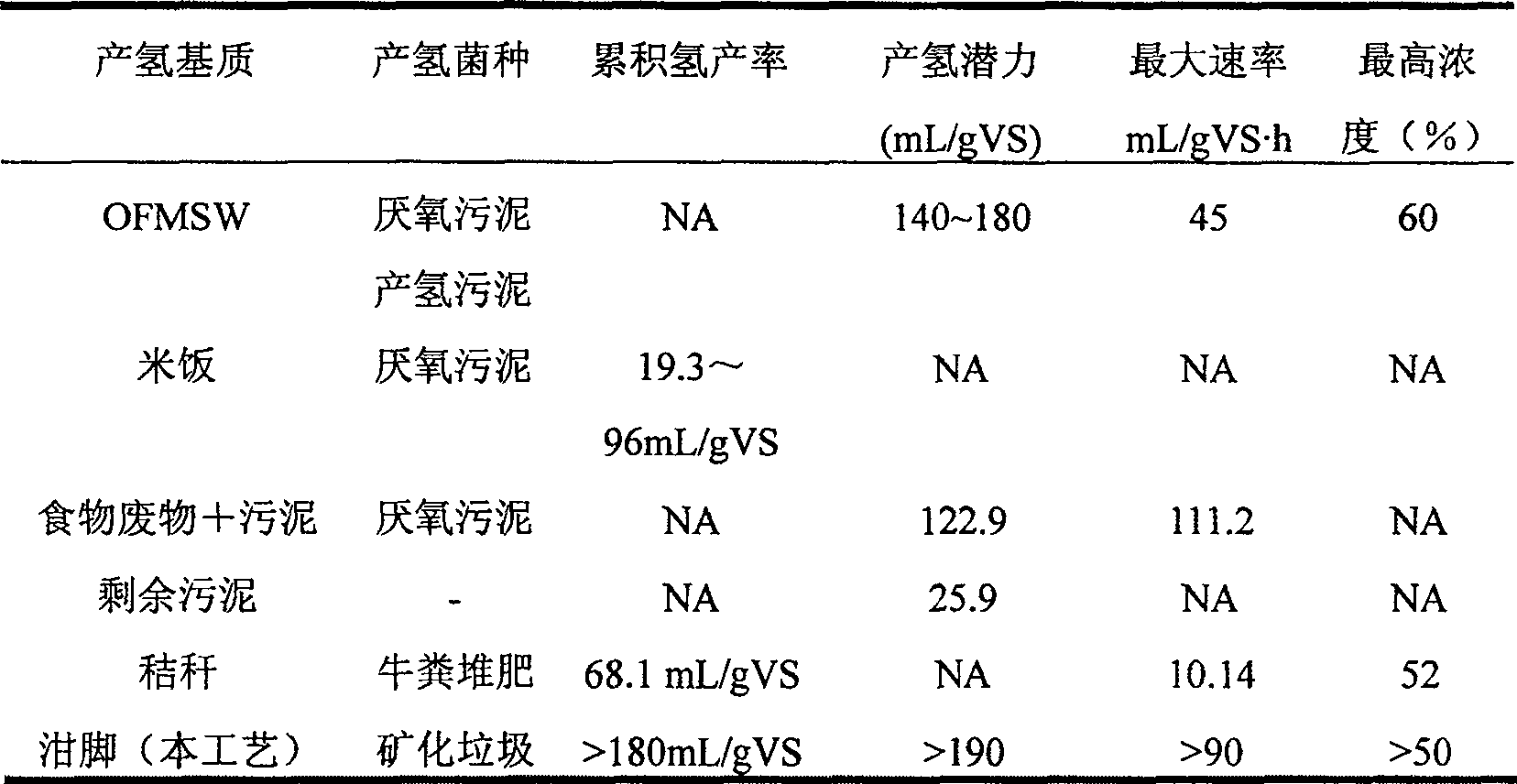

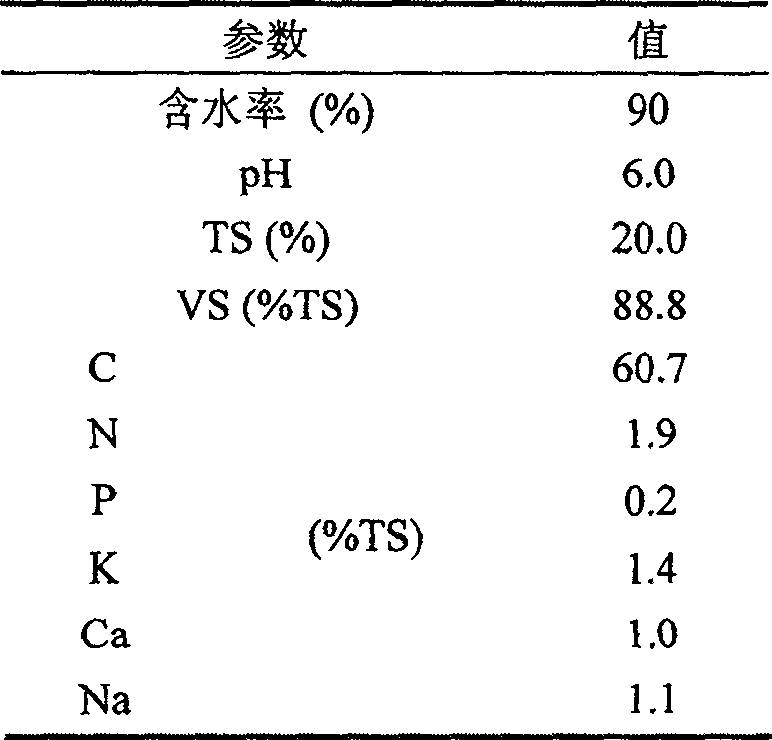

[0023] The 1-ton pilot run test was carried out in a machinery and equipment factory in Taixing, Jiangsu (equipment production cooperation unit). The slops used for the test were taken from 3 restaurants and hotels in the suburbs of Taixing, Jiangsu. They were randomly collected on site at 2 pm every day and mixed for backup. Its composition analysis is shown in Table 2.

[0024] Table 2 Analysis of characteristics of pilot scale swill waste

[0025]

[0026] Mineralized waste from a landfill site in Jiangsu, which has been closed for 3 years and whose landfill age is 15 years old, was mined and air-dried, and then sieved to a particle size of 10mm. The swill waste was crushed by a food crusher to a particle size of 10mm. The sludge was taken from anaerobic granular sludge from a UASB process sewage treatment plant in Wuxi. The proportion is mixed with the swill waste, and the above mixture is sterilized by dry heat sterilization at 150°C for 30 minutes, and then put into ...

Embodiment 2

[0028] The composition of swill waste collected by a 100t / d solid waste treatment plant in Shanghai is shown in Table 3:

[0029] Table 3 Analysis of characteristics of swill waste in a domestic waste treatment plant

[0030]

[0031] Mineralized waste from a landfill site in Shanghai that had been closed for 3 years and was landfilled for 10 years was mined and air-dried, and sieved to a particle size of 5mm. The swill waste is crushed by a food crusher to a particle size of 10mm. The anaerobic sludge is taken from the concentration pool of the adjacent chemical first-level process sewage plant. The ratio of the swill waste is mixed with the swill waste, and the above mixture is sterilized by 100°C, 30min moist heat sterilization, and then the swill waste dry weight is put into the screened mineralized garbage at a ratio of 5:1. After adjusting the moisture content to 75% to 90%, put it into a constant temperature (55°C) anaerobic fermentation reaction tank. The headspace v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com