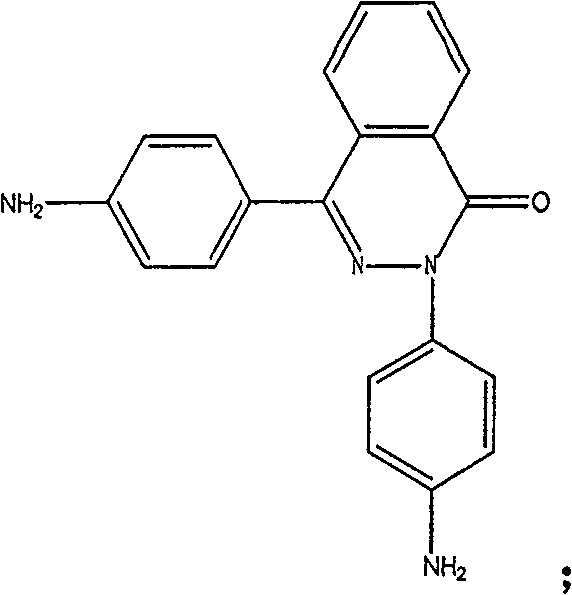

PPTA containing 2,4 di (4-amino phenyl)-2,3-diaza naphthalene-1-one and preparation process thereof

A manufacturing method, the technology of poly-p-phenylene terephthalamide, which is applied in the polymerization of para-polyarylamide and the synthesis of high polymers, can solve the problems of insoluble and infusible PPTA resin, resistance to strong acid corrosion, and processing difficulties and other problems, to achieve the effect of good solubility, good electrical insulation performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

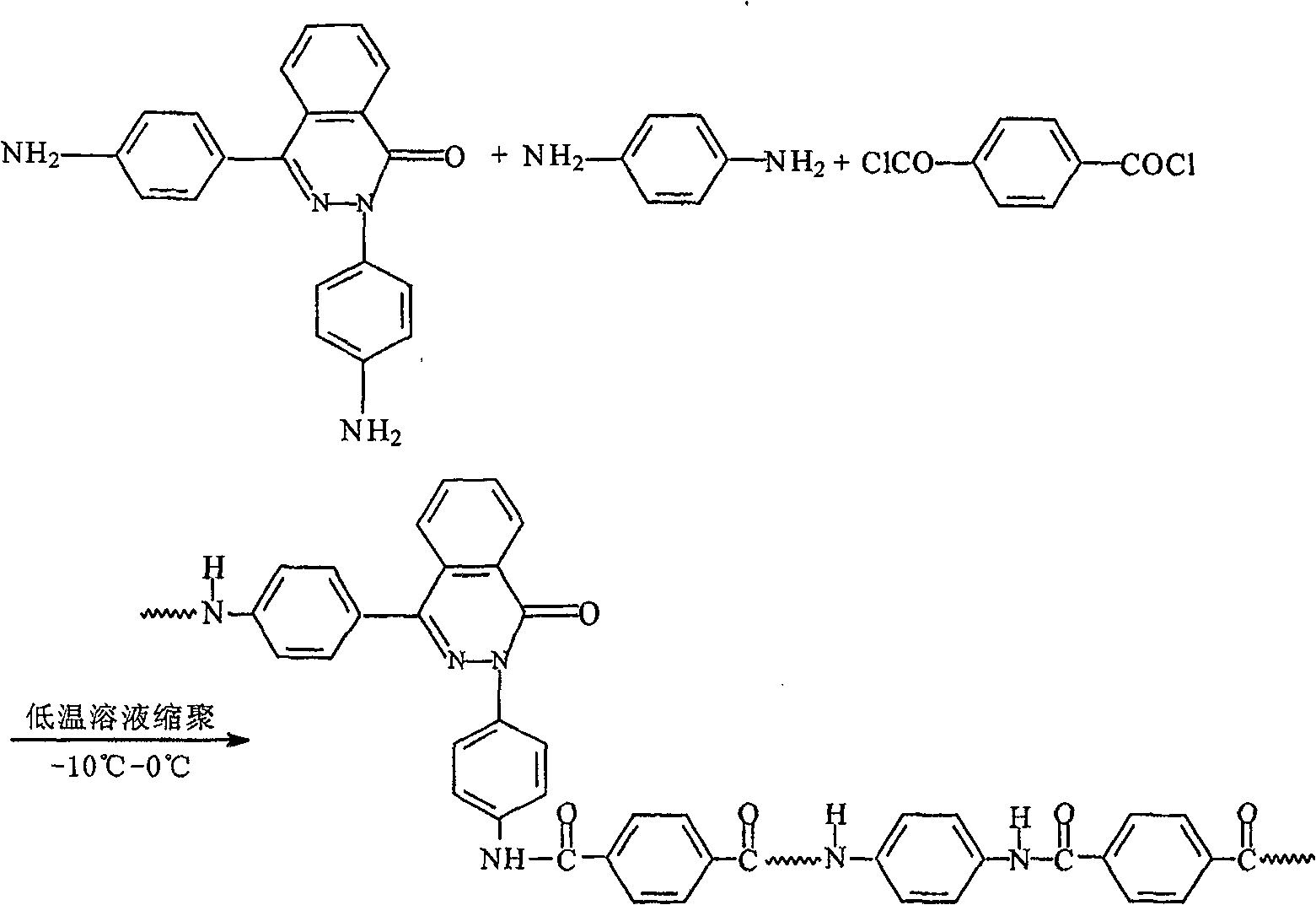

Method used

Image

Examples

Embodiment 1

[0015] Add 100ml NMP to a 250ml three-necked flask, N 2 protection, stirring, adding a certain amount of CaCl 2 , slowly warming up to 70°C, after completely dissolving, cooling to room temperature, adding 3.078 grams of p-phenylenediamine and 0.492 grams of 2,4-bis(4-aminophenyl)-2,3-naphthyridine-1-one , when all the materials are dissolved, cool to -5°C, add 6.090 grams of terephthaloyl chloride, accelerate stirring until rod climbing occurs, react for 30 minutes, add 2.22 grams of Ca(OH) 2 Neutralize for 20 minutes to obtain a co-polycondensation PPTA solution. The prepared solution was thoroughly washed with water and dried to obtain a new type of PPTA resin, whose characteristic viscosity measured in 98% concentrated sulfuric acid was 3.2. The PPTA can be dissolved into NMP, or solution-spun.

Embodiment 2

[0017] Add 100ml NMP to a 250ml three-necked flask, N 2 protection, stirring, adding a certain amount of CaCl 2 , slowly heat up to 70°C, dissolve, cool to room temperature, add 3.888 grams of p-phenylenediamine, wait until the material is completely dissolved, cool to -5°C, add 8.12 grams of terephthaloyl chloride, react for 10 minutes, and synthesize a certain degree of polymerization For oligomers, add 1.312 grams of 2,4-bis(4-aminophenyl)-2,3-naphthyridine-1-one, after dissolving, add 1 gram of terephthaloyl dichloride, and accelerate stirring until pole climbing occurs Phenomenon, react for 30 minutes, add 2.96 grams of Ca(OH) 2 Neutralize for 20 minutes to obtain a PPTA co-condensation solution. The prepared solution is thoroughly washed with water and dried to obtain a novel PPTA resin whose characteristic viscosity is 2.8 as measured in 98% concentrated sulfuric acid. The PPTA can be dissolved into NMP, or solution-spun.

[0018] The structure of the polymer is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com