Polyurethane/vinyl polymer IPN bi-component damping material

A vinyl polymer, damping material technology, applied in the field of polyurethane/vinyl polymer IPN two-component damping materials, damping materials, can solve the problems of heat resistance, oxidative resistance, hydrolysis stability, poor corrosion resistance, etc. The effect of simple construction, convenient storage and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Synthesis of polyurethane prepolymer:

[0023] Add 50 grams of hydroxyl-terminated polybutadiene / acrylonitrile liquid rubber into a four-necked bottle equipped with a stirring blade, a thermometer, a dropping device, and an air guide tube, vacuumize at 75° C., and pretreat for 4 hours. Then the temperature was lowered to 60°C, and nitrogen was blown. Add 0.025 g of dibutyltin dilaurate catalyst and 5.9 g of toluene diisocyanate preheated to 60°C, stir for 5 minutes, raise the temperature to 75°C, control the temperature at 75±1°C, and react for 3 hours.

[0024] 2) Preparation of the first component (A):

[0025] Accurately weigh 40 grams of polyurethane prepolymer, 0.1971 grams of benzoyl peroxide, and 10 grams of ethyl acetate, and stir evenly to form component A.

[0026] 3) Preparation of the second component (B):

[0027] Accurately weigh 5 grams of ethyl acetate, 6.89 grams of butyl methacrylate, 6.89 grams of butyl acrylate, 0.725 grams of α-hydroxyethyl me...

Embodiment 2

[0032] 1) repeat 1) step in embodiment 1,

[0033] 2) Preparation of the first component (A):

[0034] Accurately weigh 40 grams of polyurethane prepolymer, 0.058 grams of benzoyl peroxide, and 10 grams of ethyl acetate, and stir evenly to form component A.

[0035] 3) Preparation of the second component (B):

[0036] Accurately weigh 5 grams of ethyl acetate, 6.89 grams of butyl methacrylate, 6.89 grams of butyl acrylate, 0.725 grams of α-hydroxyethyl methacrylate, 0.029 grams of N, N-dimethylaniline, 0.102 grams of Dibutyltin laurate, 0.1971g of 1,4-butanediol, 0.1957g of trimethylolpropane, stir evenly, that is component B.

[0037] 4) Preparation of polyurethane / vinyl polymer IPN two-component damping material:

[0038] Mix components A and B according to a weight ratio of 70:30 and a molar ratio of -NCO / -OH of 1.2, stir evenly, remove air bubbles, cast into a film, place at room temperature, and obtain a damping material after curing.

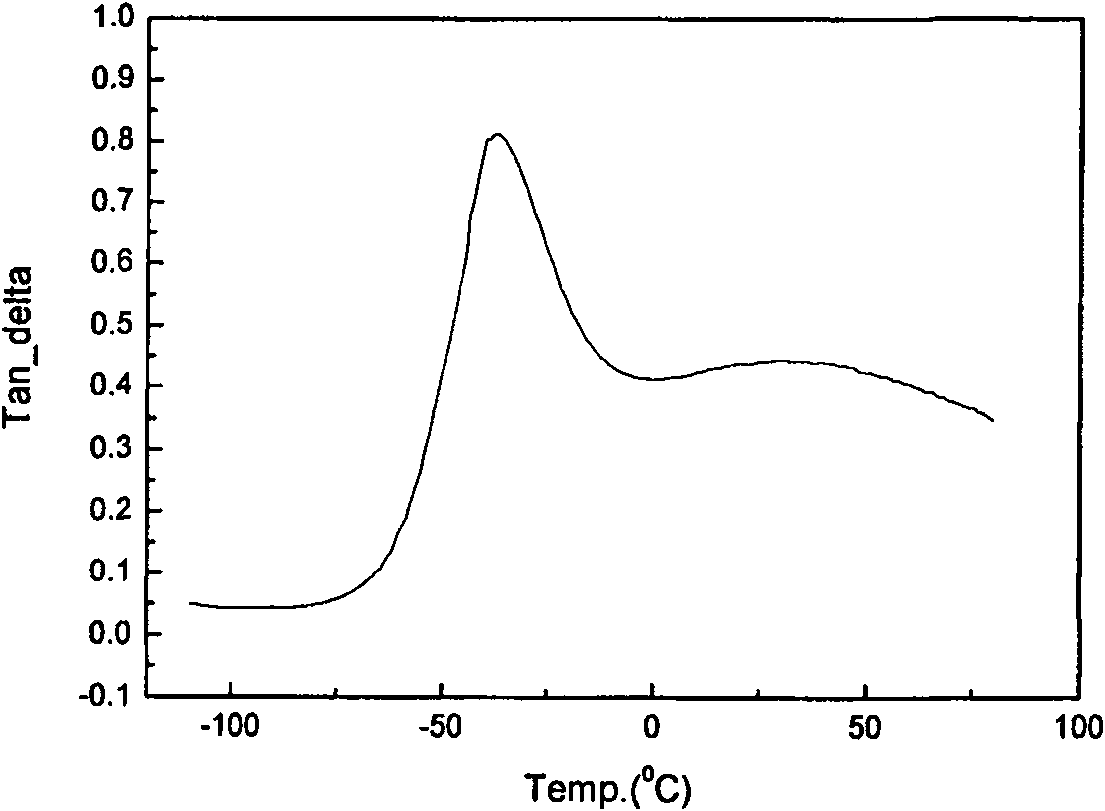

[0039] figure 2 It is the dyn...

Embodiment 3

[0041] 1) repeat 1) step in embodiment 1,

[0042] 2) Preparation of the first component (A):

[0043] Accurately weigh 40 grams of polyurethane prepolymer, 0.1018 grams of benzoyl peroxide, and 10 grams of ethyl acetate, and stir evenly to form component A.

[0044] 3) Preparation of the second component (B):

[0045]Accurately weigh 5 grams of ethyl acetate, 13.78 grams of butyl methacrylate, 0.725 grams of α-hydroxyethyl methacrylate, 0.0509 grams of N, N-dimethylaniline, 0.102 grams of dibutyltin dilaurate, 0.1971 gram of 1,4-butanediol, 0.1957 gram of trimethylolpropane, stir evenly, that is, component B.

[0046] 4) Preparation of polyurethane / vinyl polymer IPN two-component damping material:

[0047] Mix components A and B according to a weight ratio of 70:30 and a molar ratio of -NCO / -OH of 1.2, stir evenly, remove air bubbles, cast into a film, place at room temperature, and obtain a damping material after curing.

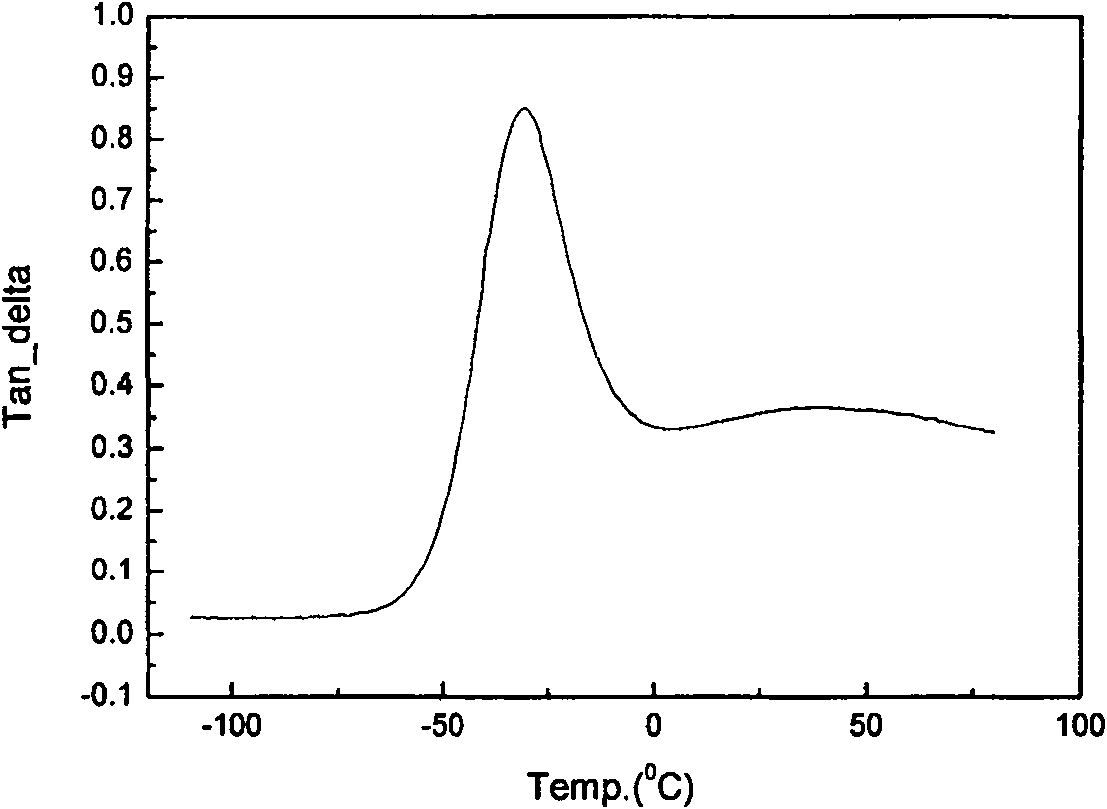

[0048] image 3 It is the dynamic mechanical pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com