Water thinned polishing oil for offset line and its prepn

A water-based varnish and connecting technology, applied in the field of chemical coatings, can solve the problems of gloss, drying and wear resistance, and achieve the effect of strong transparency, simple production process and accelerated drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

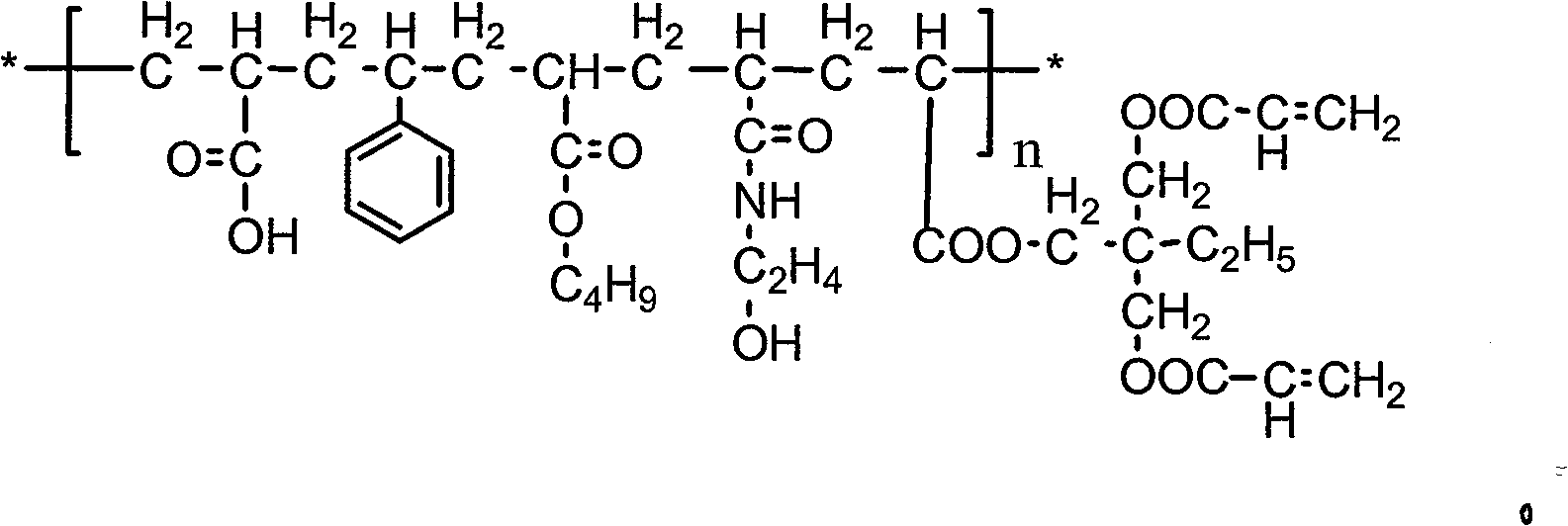

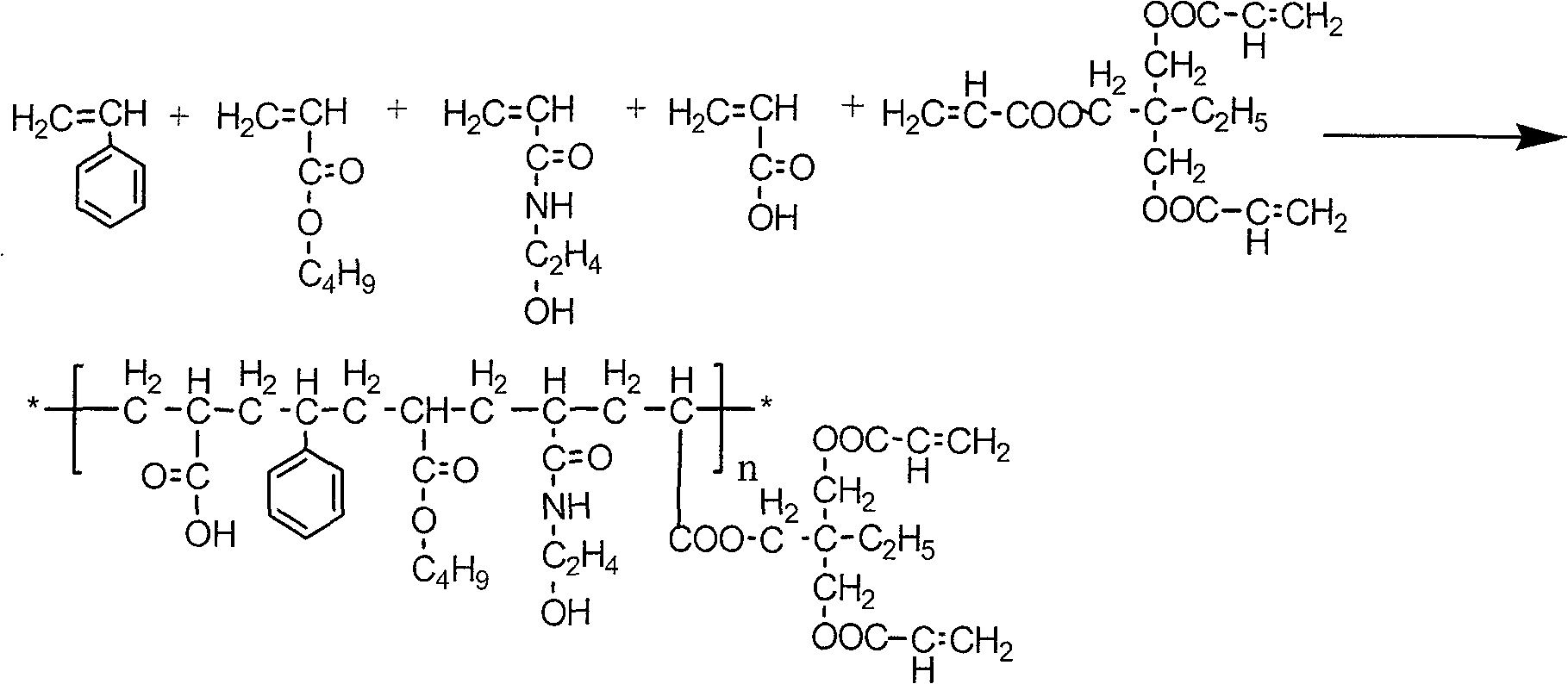

Image

Examples

Embodiment 1

[0021] 1. Preparation of acrylate resin emulsion containing trifunctional monomer and N-hydroxyethylacrylamide:

[0022] Put 250g of deionized water, 95g of styrene, 50g of butyl acrylate, 10g of functional monomer trifunctional acrylate and N-hydroxyethyl acrylamide into the three-necked flask. 10g, potassium persulfate 1g, sodium bisulfite 1g, disodium hydrogen phosphate 1g, polyvinyl alcohol 0.5g. Then, the emulsion was synthesized by the seed emulsion polymerization method, and the temperature was adjusted to 80°C and the rotation speed was 1500rps / m to obtain a stable emulsion.

[0023] 2. Prepare in-line water-based varnish:

[0024] Take 50g of the prepared styrene-acrylate resin emulsion, 5g of solid acrylic acid resin aqueous solution, 20g of film-forming acrylic acid emulsion, 10g of polyethylene wax emulsion, 2g of water-based silicone leveling agent, and 2g of silicone disinfectant. Foam agent 1g, deionized water 12g. Add in the mixing tank successively, start t...

Embodiment 2

[0028] 1. Preparation of acrylate resin emulsion containing trifunctional monomer and N-hydroxyethylacrylamide:

[0029] Put 250g of deionized water, 125g of styrene, 80g of butyl acrylate, 20g of functional monomer trifunctional acrylate and N-hydroxyethyl acrylamide into the three-necked flask. 15g, potassium persulfate 3g, sodium bisulfite 3g, disodium hydrogen phosphate 3g, polyvinyl alcohol 1.5g. Then, the emulsion was synthesized by the seed emulsion polymerization method, and the temperature was adjusted to 120°C and the rotation speed was 2500rps / m to obtain a stable emulsion.

[0030] 2. Prepare in-line water-based varnish:

[0031] Take respectively 55g of the prepared styrene-acrylate resin emulsion, 15g of solid acrylic acid resin aqueous solution, 15g of film-forming acrylic acid emulsion, 5g of polyethylene wax emulsion, 2g of water-based silicone leveling agent, and 2g of silicone disinfectant. Add 1 g of foaming agent and 7 g of deionized water into the mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com