Modification of xylanase to improve thermophilicity, alkophilicity and thermostability

A technology of xylanase and Trichoderma reesei, applied in the field of xylanase, can solve the problem of not developing thermophilic and basophilic family 11 xylanase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

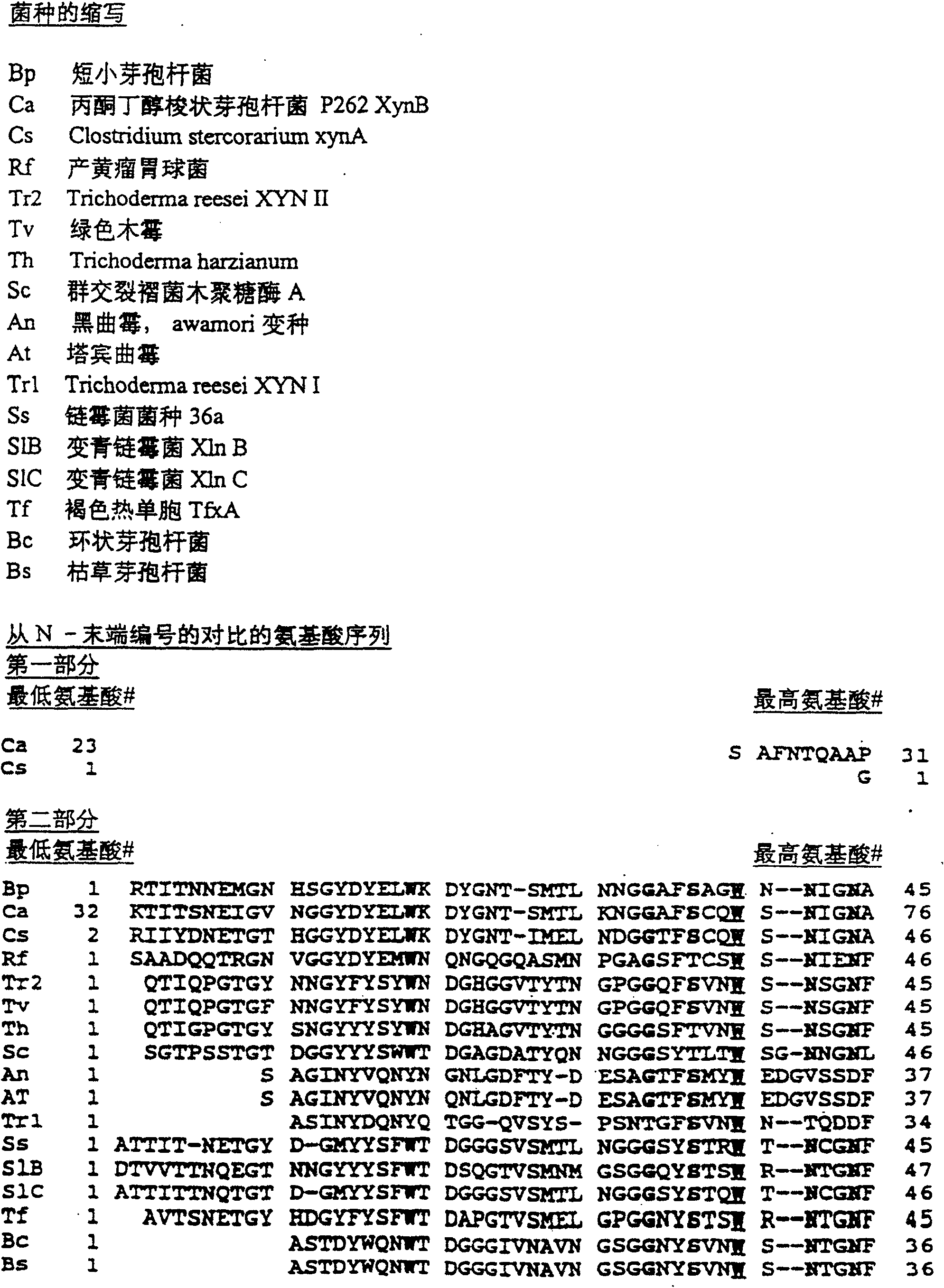

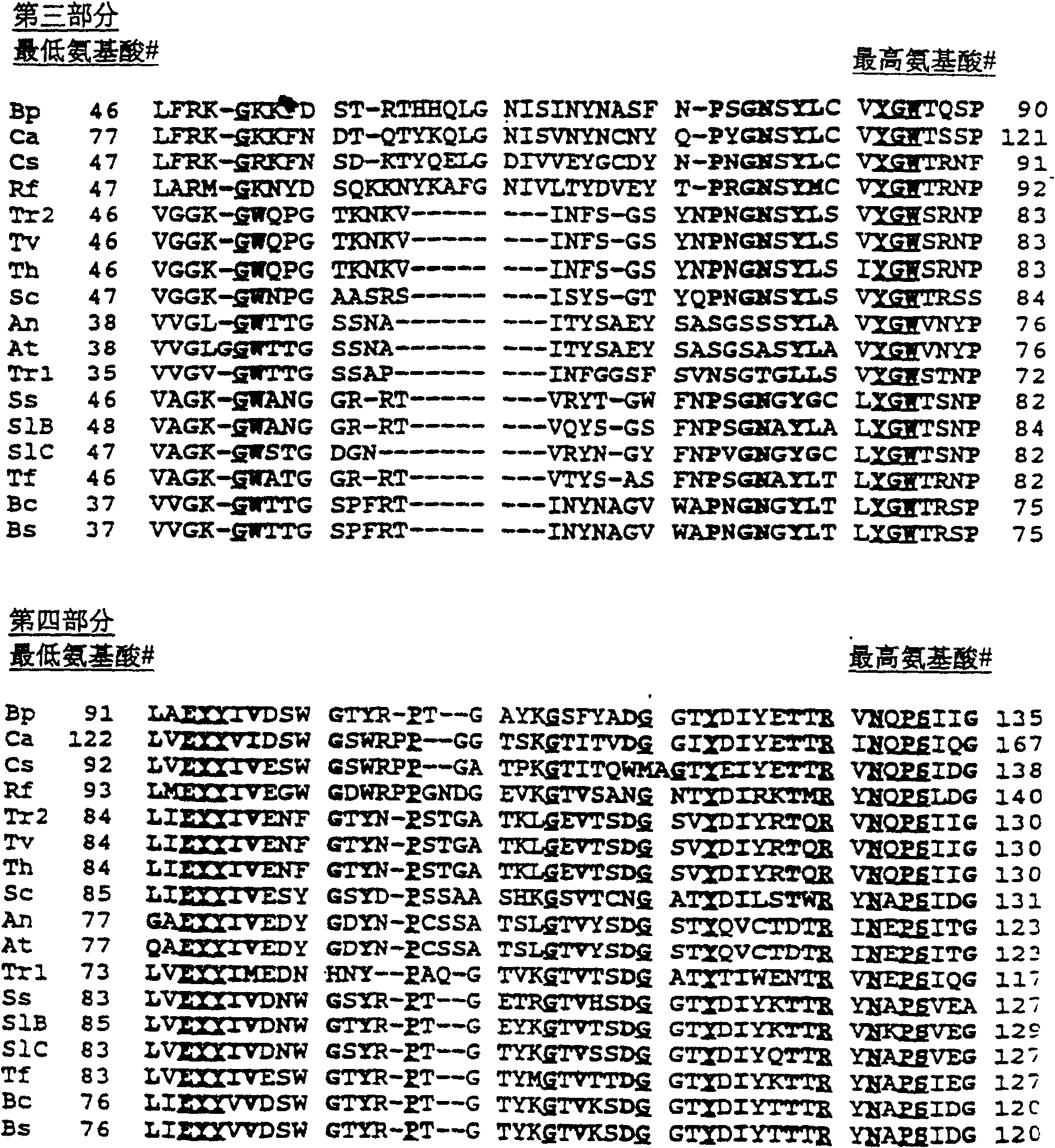

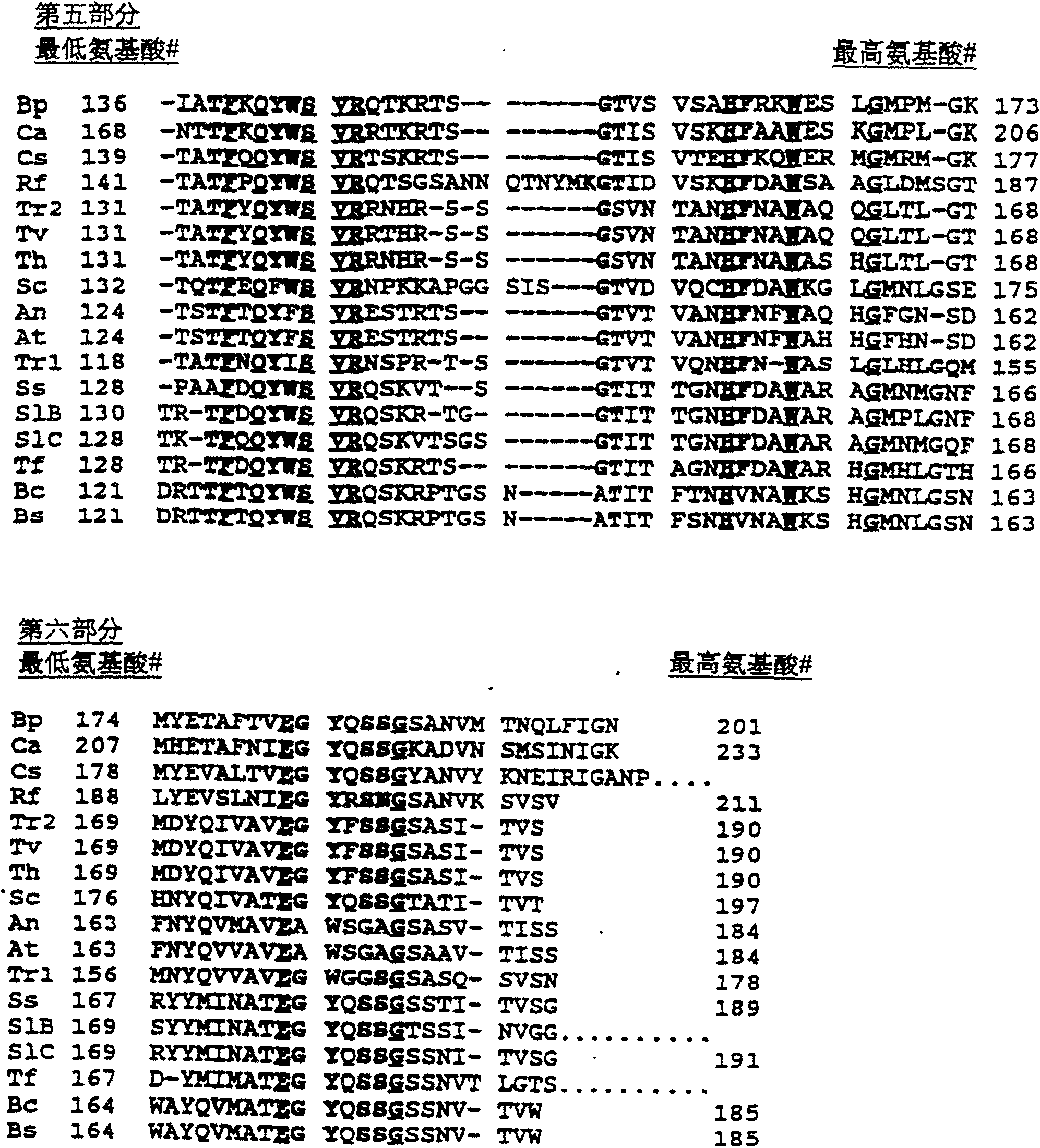

Image

Examples

Embodiment 1

[0141] Construction of Trichoderma Reesei modified xylanase NI-TX

[0142] Basic recombinant DNA methods such as plasmid preparation, restriction enzyme digestion, polymerase chain reaction, oligonucleotide phosphorylation, ligation, transformation, and DNA hybridization are based on well-established methods well known to those skilled in the art (Sung et al. ., 1986) or according to the method recommended by the manufacturer of the enzyme or kit. Buffers for many enzymes are provided as part of a kit or reconstituted according to the manufacturer's recommendations. Restriction enzymes, T4 polynucleotide kinase and T4 DNA The ligase was purchased from New England BioLabs LTD, Mississauga, Ont. The GeneAmp PCR kit was purchased from Perkin-Elmer. The starting plasmid pXYbc is a pUC-type plasmid inserted into the Bacillus circulans xylanase gene, here It has been prepared and published before (Sung et al, 1993; Campbell et al, US Patent 5,405,769, issued April 11, 1995). A commo...

Embodiment 2

[0308] Construction of mutant xylanase NI-BX from Bacillus circulans

[0309]Modifications of the fungal Trichoderma xylanase NI-TX2, NI-TX3, NI-TX7, NI-TX8 and NI-TX9 are also reproduced in the bacterial Bacillus circulans xylanase (BcX). The starting plasmid pXYbc is in It has been prepared and published before (Sung et al, 1993; Campbell et al, US patent 5,405,769, authorized on April 11, 1995), and is only briefly described here. It is used for pXyTv (3-190 ) same method, a synthetic gene encoding Bacillus circulans xylanase (BcX) was assembled by enzymatic phosphorylation with T4 DNA kinase and ligation of overlapping synthetic oligonucleotides into a linearized plasmid by T4 DNA ligase ( Figure 4 ) (Sung et al., 1993).

[0310] A. Construction of plasmid pNI-BXI

[0311] The modification method of NI-BX1 has been used in the preparation of NI-TX2. The mutant NI-BX1 is a modified version of BcX, which replaces the (1-22) region of BcX with the Tfx (1-31) sequence. In ...

Embodiment 3

[0373] Generation and analysis of modified xylanases

[0374] (A) Production of xylanase

[0375] The culture conditions are the same as the mature method for the production of xylanase expressed by other Escherichia coli. Dissolve 5 ml in 2YT medium (16 g yeast extract, 10 g tryptone, 5 g NaCl, 1 L) containing ampicillin (100 mg / L) The overnight culture in water) was added to 2YT medium (1L) containing ampicillin. Shaking culture (200rpm) at 37°C, after 16 hours, the cells were harvested.

[0376] (B) Purification of modified xylanase

[0377] To prepare protein samples from cells, first grind 10 g of cell samples with 25 g of aluminum powder to prepare cell extracts. After grinding into a homogeneous mixture, add a small amount (5 mL) of ice-cold buffer A (10 mM sodium acetate, pH 5.5, for BcX mutation body) or buffer B (10 mM sodium acetate, pH 4.6, for the TX mutant), and the mixture was triturated vigorously between each addition. The mixture was centrifuged at 8000 x g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com