Power generator internal cooling water oxygen removal or electrolemma microalkalination treatment device and its treatment method

A treatment device and generator technology, applied in the direction of electrochemical water/sewage treatment, electromechanical devices, water/sewage treatment, etc., can solve the problems of easy increase of water conductivity, alarm of conductivity exceeding the standard, and large floor area, etc., to achieve Solve the effects of internal cooling water corrosion, moderate pH value, and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

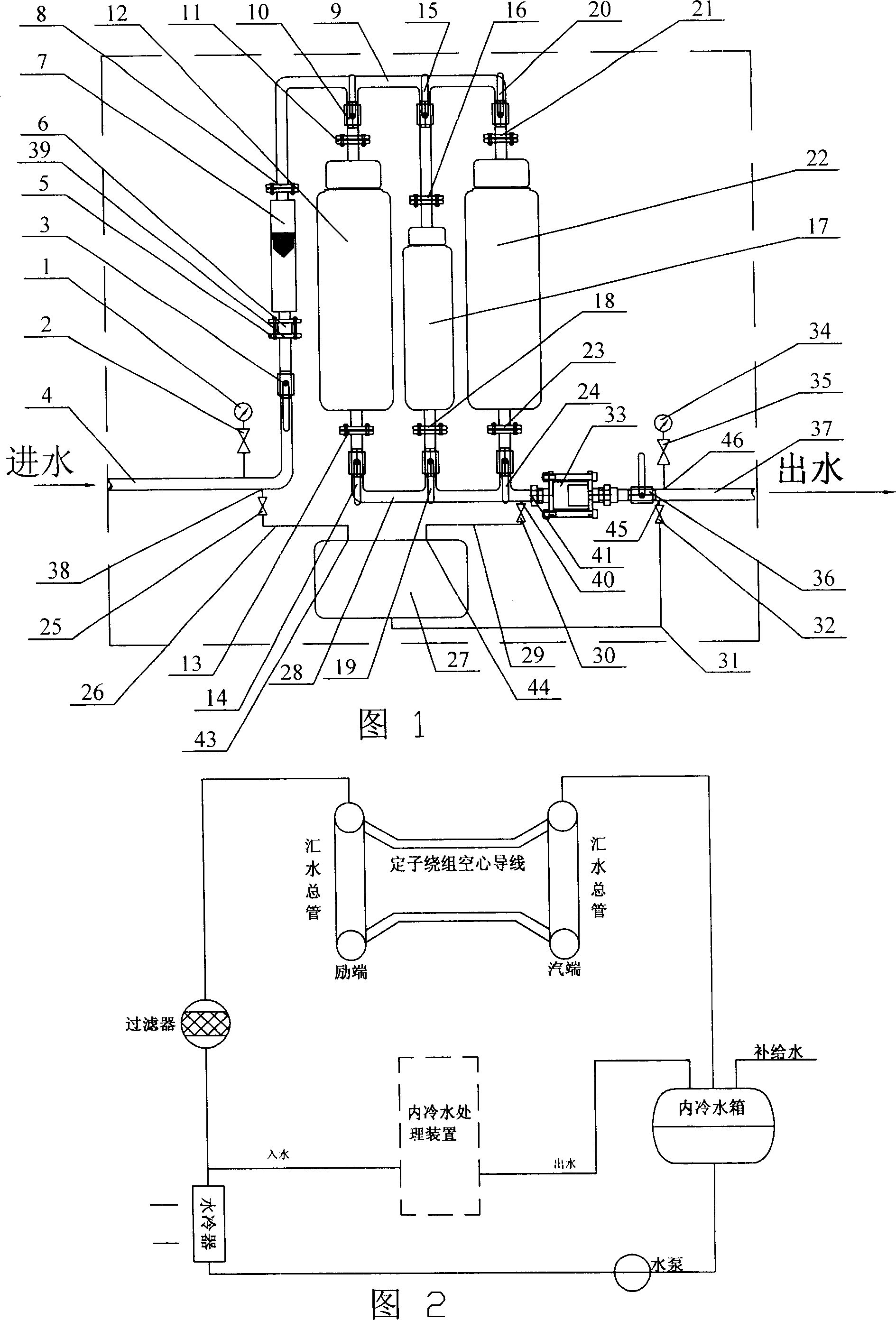

[0036] Specific embodiment one: (referring to Fig. 1 and Fig. 2) the water inlet of the device of this embodiment is communicated with the water outlet of water cooler, and the water outlet is communicated with the water inlet of inner cooling water tank, and it is equipped with water inlet pressure gauge 1, The first water inlet pipe 4, the first flange 5, the check valve 6, the rotameter 7, the second flange 8, the second water inlet pipe 9, the water inlet of the first valve 2 and the second valve 3 are equipped with a third The valve 10, the third flange 11 and the first deionizer 12 with the fourth flange 13 and the fourth valve 14 are installed at the water outlet, the fifth valve 15 and the fifth flange 16 are installed at the water inlet, and the water outlet is equipped with The sixth flange 18 and the sixth valve 19 electromembrane micro alkalinizer 17, the water inlet are equipped with the seventh valve 20 and the seventh flange 21 and the water outlet is equipped wi...

specific Embodiment approach 2

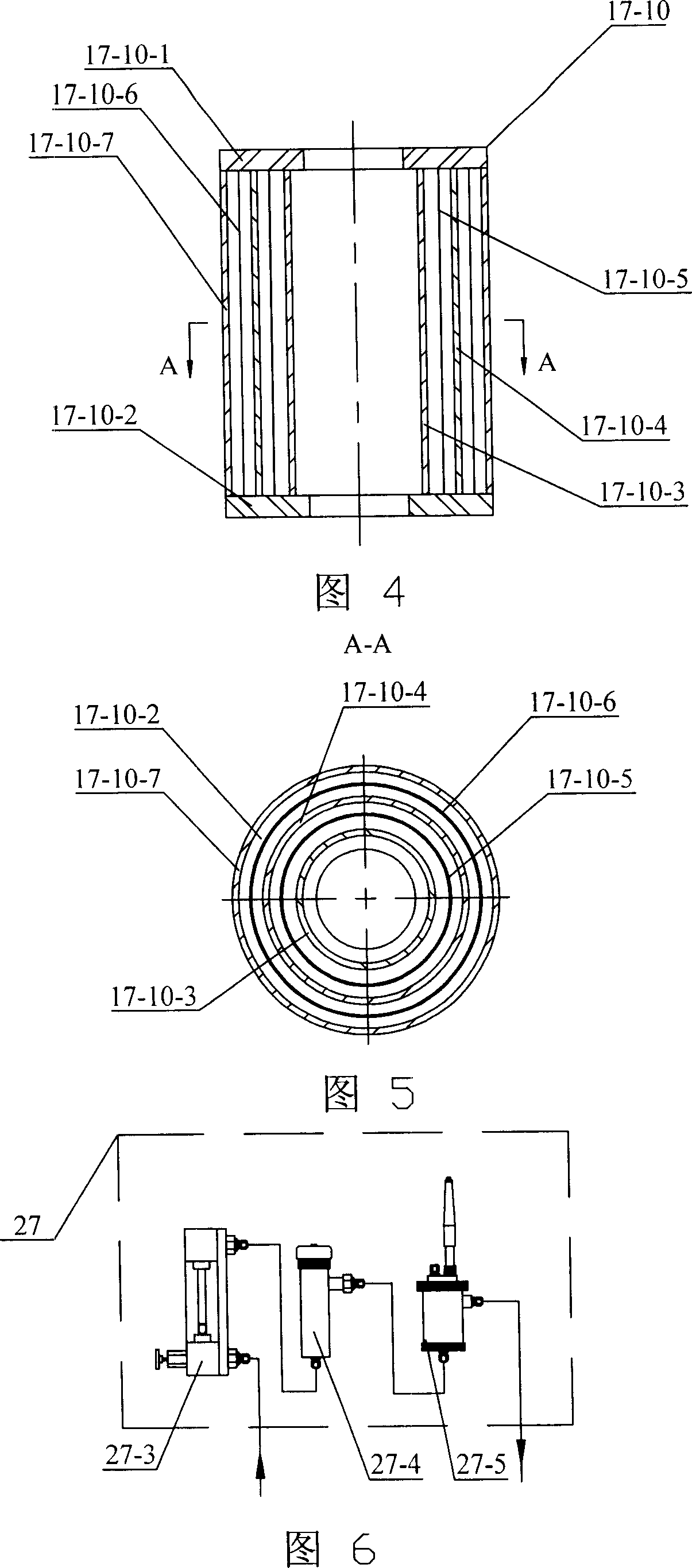

[0037] Specific embodiment two: (referring to Fig. 6 and Fig. 8) the inside of detecting meter box 27 is made up of rotameter 27-3, conductivity transmitter 27-4, PH transmitter 27-5, intelligent controller 27 in the present embodiment -6. Composed of two-in-one instrument 27-7 and power supply 27-8; the inner cooling water enters from the water inlet of the test instrument box 27 and flows through the rotameter 27-3, conductivity transmitter 27-4, and PH transmitter 27 -5, then flow out from the water outlet of the instrumentation box 27; the inner cooling water is connected with the power supply input end of the intelligent controller 27-6 and the two-in-one instrument 27-7 respectively by the power supply 27-8 output of the instrumentation box 27, The power output end of the intelligent controller 27-6 is connected with the power input end of the junction box 17-11 of the electro-film micro-alkalinizer 17. Other compositions and connections are the same as in the first embo...

specific Embodiment approach 3

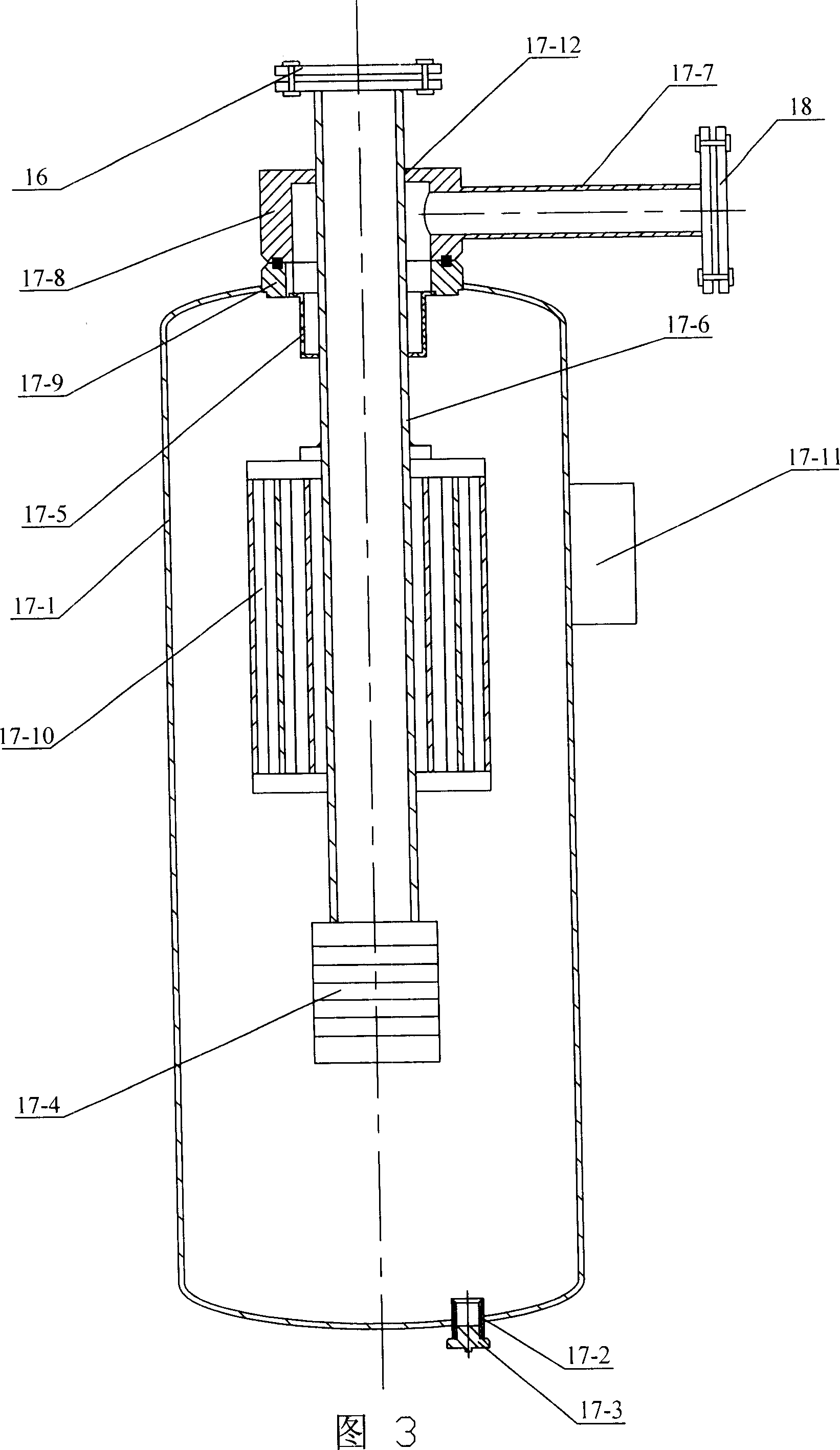

[0038] Specific embodiment three: (referring to Fig. 3) the electromembrane slight alkalinizer 17 of the present embodiment is made up of simplified form 17-1, resin replacement hole 17-2, resin replacement hole cover 17-3, water inlet water cap 17-4 , water outlet water cap 17-5, water inlet pipe 17-6, water outlet pipe 17-7, upper fixed sleeve 17-8, lower fixed sleeve 17-9, bipolar membrane device 17-10 and junction box 17-11; Five flanges 16 communicate with the water inlet pipe, and the top of the water inlet pipe is fixedly connected with the hole 17-12 in the vertical direction of the upper fixed sleeve 17-8. The bottom of 6 is threadedly connected with the water inlet cap 17-4, the water inlet end of the water outlet pipe 17-7 communicates with the water outlet of the upper fixed sleeve 17-8, and the water outlet end of the water outlet pipe 17-7 communicates with the sixth flange 18 , the upper fixed sleeve 17-8 is threadedly connected with the lower fixed sleeve 17-9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com