Treatment of waste water in vanadium pentaoxide production and its full circulation technology

A vanadium pentoxide, full cycle technology, applied in the fields of vanadium oxide, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as wastewater pollution, and achieve the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

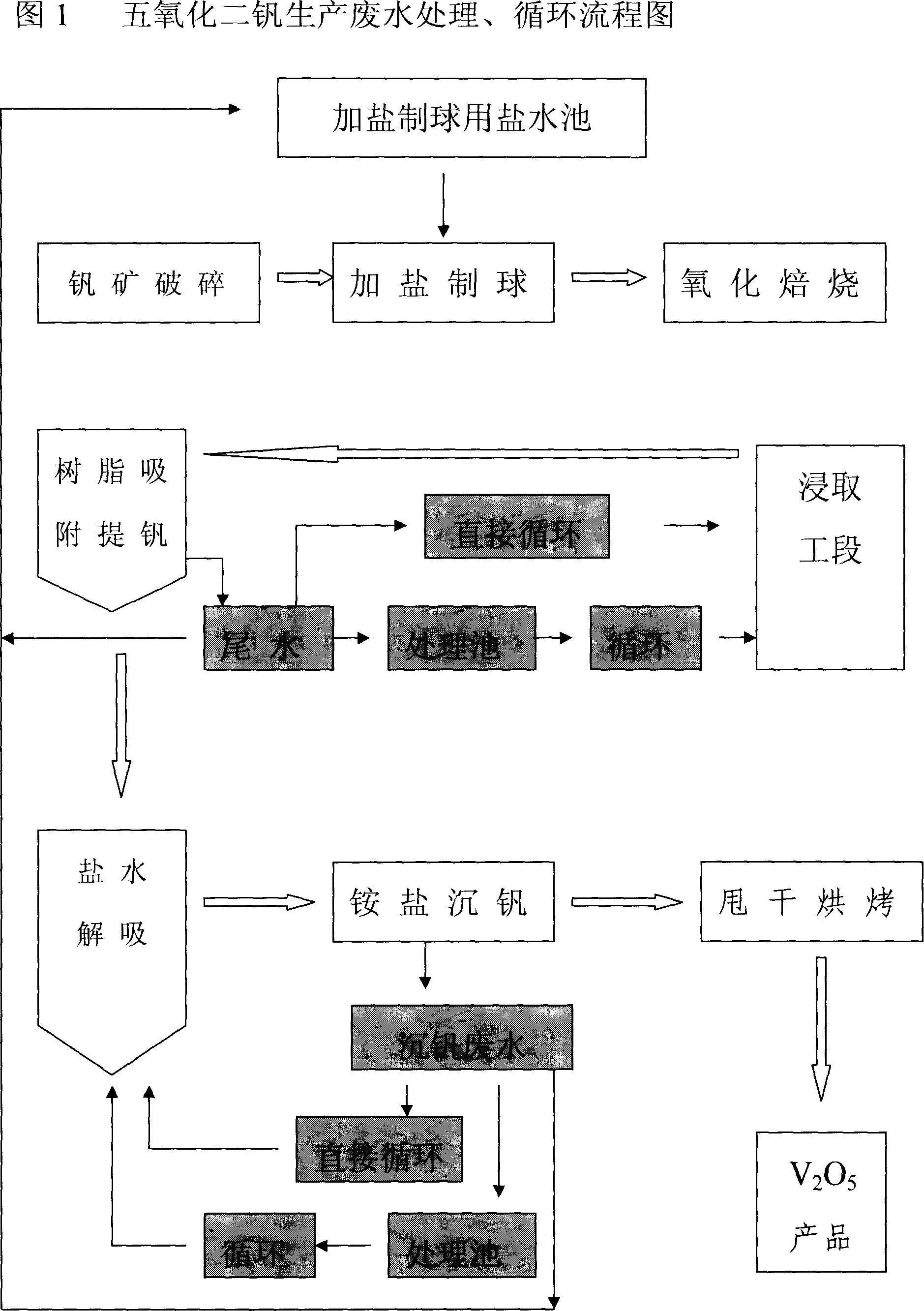

[0019] For a vanadium pentoxide production enterprise, the tail water of its resin purification section and the treatment and circulation process of ammonium salt vanadium precipitation wastewater are shown in Figure 1.

[0020] 1. The treatment and circulation of the tail water in the resin adsorption purification section: through vanadium ore crushing, adding salt to make pellets, oxidation roasting, leaching, at this time the vanadium in the ore is converted into the leach solution, when the leach solution flows through the resin adsorption During the purification section, the vanadate ions are adsorbed onto the resin, and the tail water after the vanadate ions are adsorbed is recycled as a leaching solution. After the tail water is continuously circulated as a leaching solution for one week, the tail water is vulcanized once. Add 2 kg of iron sulfide ore powder and 1 kg of sodium sulfide to each ton of tail water, stir, and settle still. The cleared tail water will continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com