Antioxydizing peptide mixture from collagen and its preparation process and use

A collagen and antioxidant peptide technology, applied in chemical instruments and methods, compositions for inhibiting chemical changes, non-active components of polymer compounds, etc. Activity and other issues, to achieve the effect of strong antioxidant effect, significant social and economic benefits, and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

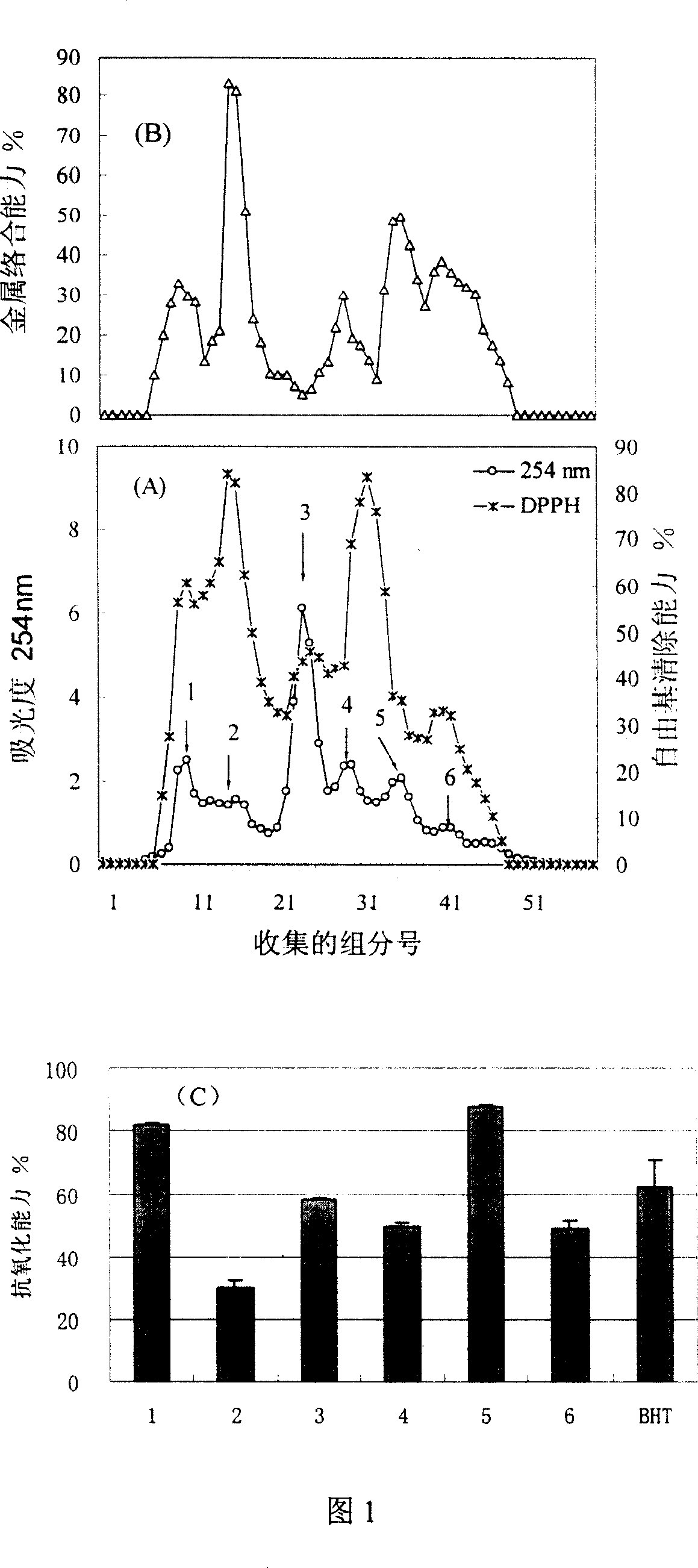

[0047] Example 1, using pepsin and pronase to hydrolyze collagen to prepare the antioxidant peptide mixture derived from collagen of the present invention

[0048] 1) At 37°C, mix the collagen powder of pigskin with purified water so that the weight percentage of the collagen in the mixed solution is 5wt%, adjust the pH value of the collagen to 2.0 with 6N hydrochloric acid, then add pepsin ( pepsin) (the weight ratio of collagen and protease is 2500: 1), carry out hydrolysis reaction for 24 hours, when hydrolysis finishes, hydrolyzate is heated at 90 ℃ for 5 minutes, then boil and keep for 3 minutes again, stop enzymolysis reaction.

[0049] At the same hydrolysis temperature, the pepsin hydrolyzate was further hydrolyzed with pronase E. First use sodium hydroxide to adjust the pH value of the pepsin hydrolyzate to 7.5, then add pronase E (pronase E) (the weight ratio of pepsin hydrolyzate and protease is 125: 1), carry out the hydrolysis reaction for 24 hours, and the hydrol...

Embodiment 2

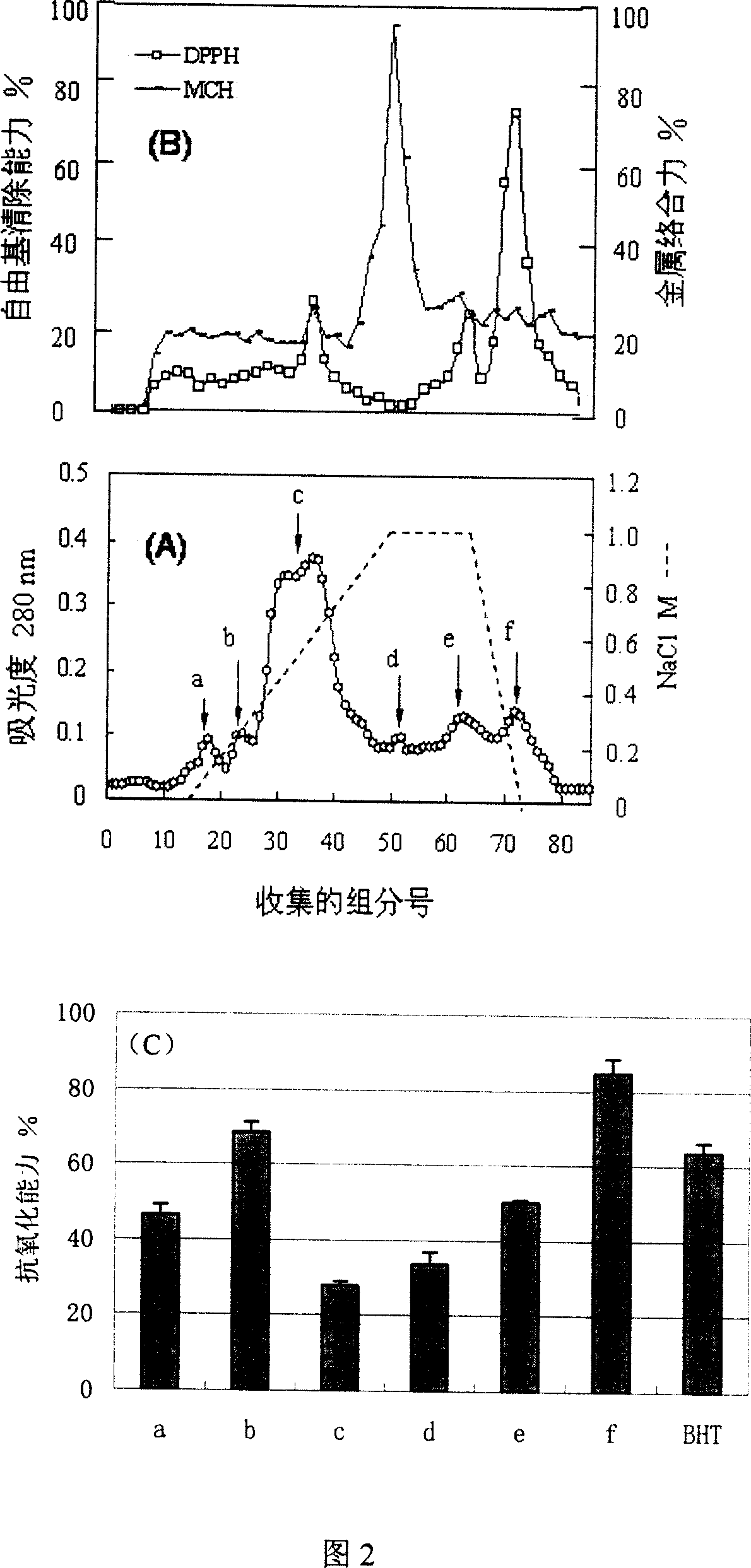

[0053] Example 2, using pepsin, papain and bovine trypsin to hydrolyze collagen to prepare the antioxidant peptide mixture derived from collagen of the present invention

[0054] 1) At 37°C, mix the collagen powder of pigskin with deionized water so that the weight percentage of the collagen in the mixture is 7wt%, adjust the pH value of the collagen to 2.0 with hydrochloric acid, and then add pepsin ) (the weight ratio of collagen and protease is 2500: 1), carry out the hydrolysis reaction for 24 hours, when the hydrolysis ends, the hydrolyzate is heated at 90° C. for 5 minutes, then boiled and then kept for 3 minutes to stop the enzymolysis reaction.

[0055] The pepsin hydrolyzate was then hydrolyzed with papain. Adjust the pH value of the above-mentioned pepsin hydrolyzate to 6.2, then add papain (papain), the weight ratio of papain and pepsin hydrolyzate is 1: 50, carry out the hydrolysis reaction at 25 ℃ for 24 hours, when the hydrolysis ends, the hydrolyzate After boil...

Embodiment 3

[0060] Example 3, using pepsin and bovine trypsin to hydrolyze collagen to prepare the antioxidant peptide mixture derived from collagen of the present invention

[0061] 1) At 37°C, mix the collagen powder of fish skin with purified water so that the weight percent of collagen in the mixed solution is 2wt%, adjust the pH value of collagen to 2.0 with 6N hydrochloric acid, then add pepsin ( pepsin) (the weight ratio of collagen and protease is 2500: 1), carry out hydrolysis reaction for 24 hours, when hydrolysis finishes, hydrolyzate is heated at 90 ℃ for 5 minutes, then boil and keep for 3 minutes again, stop enzymolysis reaction.

[0062] The pepsin hydrolyzate was then hydrolyzed with protease from bovine pancreas. Adjust the pH value of the above-mentioned pepsin hydrolyzate to 7.5, then add bovine pancreas protease (protease from bovine pancreas), the weight ratio of bovine pancreas protease and pepsin hydrolyzate is 1:125, carry out the hydrolysis reaction at 37 ° C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com