Electrode modified by chloride, oxide enzyme capable of catalyzing organic reaction in high effect

A technology of chloroperoxidase and modified electrodes, which is applied in the field of electrochemical catalysis, can solve the problems of reducing enzyme activity and achieve the effects of highly efficient catalysis of organic reactions, broad application prospects, good chiral selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The gold disc electrode is polished on metallographic sandpaper first, and then 0.3 and 0.05μm Al 2 O 3 Powder polishing. Then, it was ultrasonically cleaned with ultrapure water, then washed with 50% aqua regia, taken out, rinsed with water, and then placed in 0.2mg / mL sodium mercaptopropane sulfonate (MPS) in ethanol solution for 16h, 3mg / mL poly 2 Assembled in allyl dimethyl ammonium chloride (PDDA) solution for 30 minutes, 3.95x10 -6 It was assembled in mol / L CPO (pH=5.0) for 10 hours, and then moved to 3mg / mL PDDA for 30 minutes. After rinsing with ultrapure water, a modified electrode with immobilized CPO is prepared, which is referred to as PDDA-CPO-PDDA-MPS / Au electrode, which can be used to catalyze organic chemical reactions.

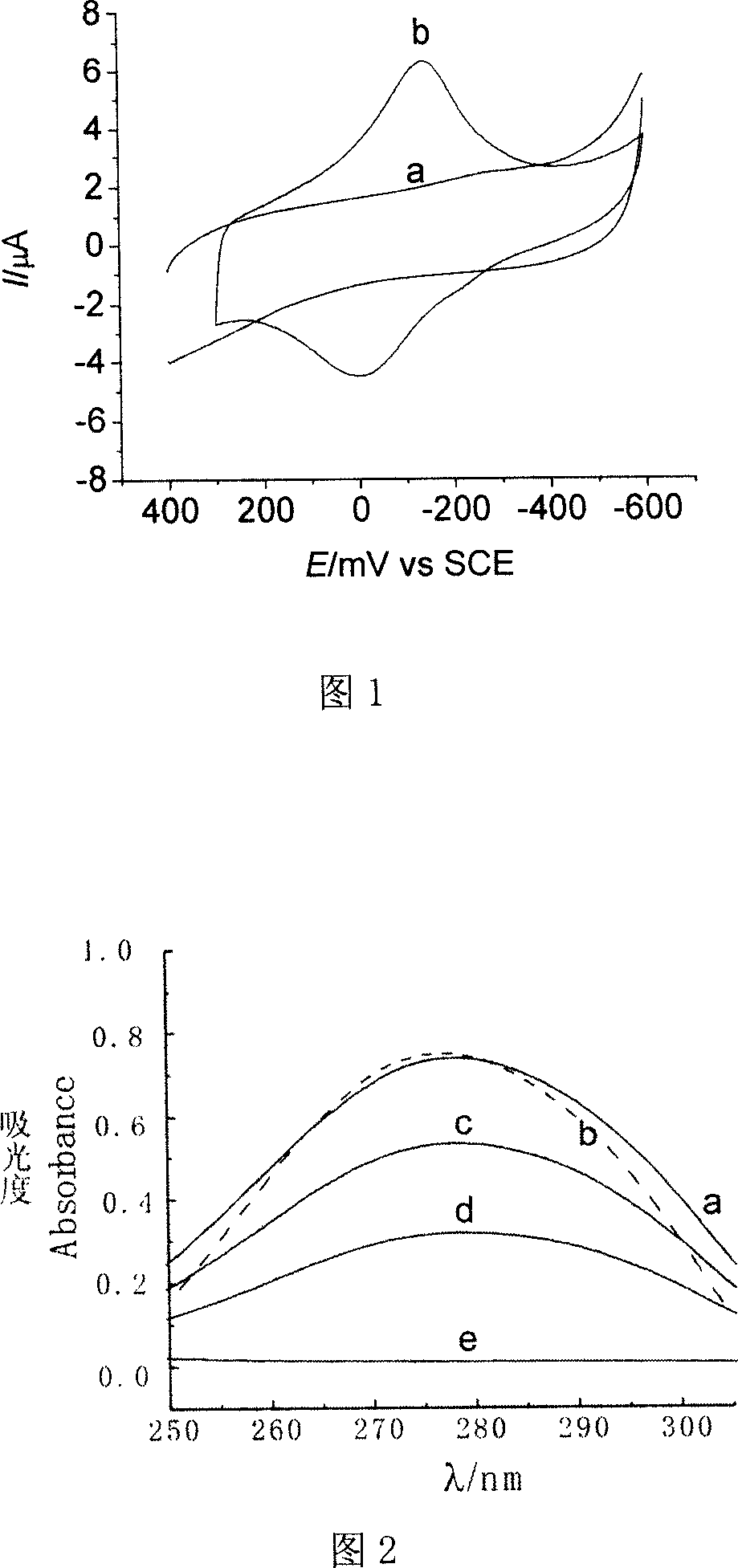

[0041] Use this electrode as the working electrode, the saturated calomel electrode (SCE) as the reference electrode, and the platinum electrode as the auxiliary electrode. Under anaerobic conditions, perform cyclic voltammetric scanning an...

Embodiment 2

[0043] Take 8mL phosphate buffer solution (pH=2.75) of 0.1mmol / L monochlorodimethanone as the base solution, and use the PDDA-CPO-PDDA-MPS / Au electrode prepared in Example 1 as the working electrode. The mercury electrode (SCE) is the reference electrode, and the platinum electrode is the auxiliary electrode. Saturate with oxygen before the reaction, and maintain an oxygen atmosphere during the reaction. The electrolysis is carried out at a potential of -0.6V. The absorbance change before and after electrolysis was measured with an ultraviolet spectrum analyzer. The result is shown in Figure 2.

[0044] The experimental results of the modified electrode for the catalytic chlorination of monochlorodimethanone are shown in Figure 2. It can be clearly seen that curve a is the absorbance of the monochlorodimethone solution before electrolysis; the modified electrode without fixed CPO is the working electrode after 1h electrolysis in the monochlorodimethone solution, the characteristic U...

Embodiment 3

[0047] Use another polycation polyethyleneimine (PEI) to replace the PDDA in Example 1. The other steps are the same as in Example 1. The CPO modified PEI-CPO-PEI-MPS / Au electrode can also obtain the same Catalytic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com