Height tropism zinc oxide nano column array ultrasonic auxiliary water solution preparation method

A nano-pillar array, ultrasonic-assisted technology, applied in nanostructure manufacturing, chemical instruments and methods, zinc oxide/zinc hydroxide, etc., can solve the problems of restricted application, reduced growth rate, large average diameter, etc., to ensure high orientation. performance, simple equipment, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

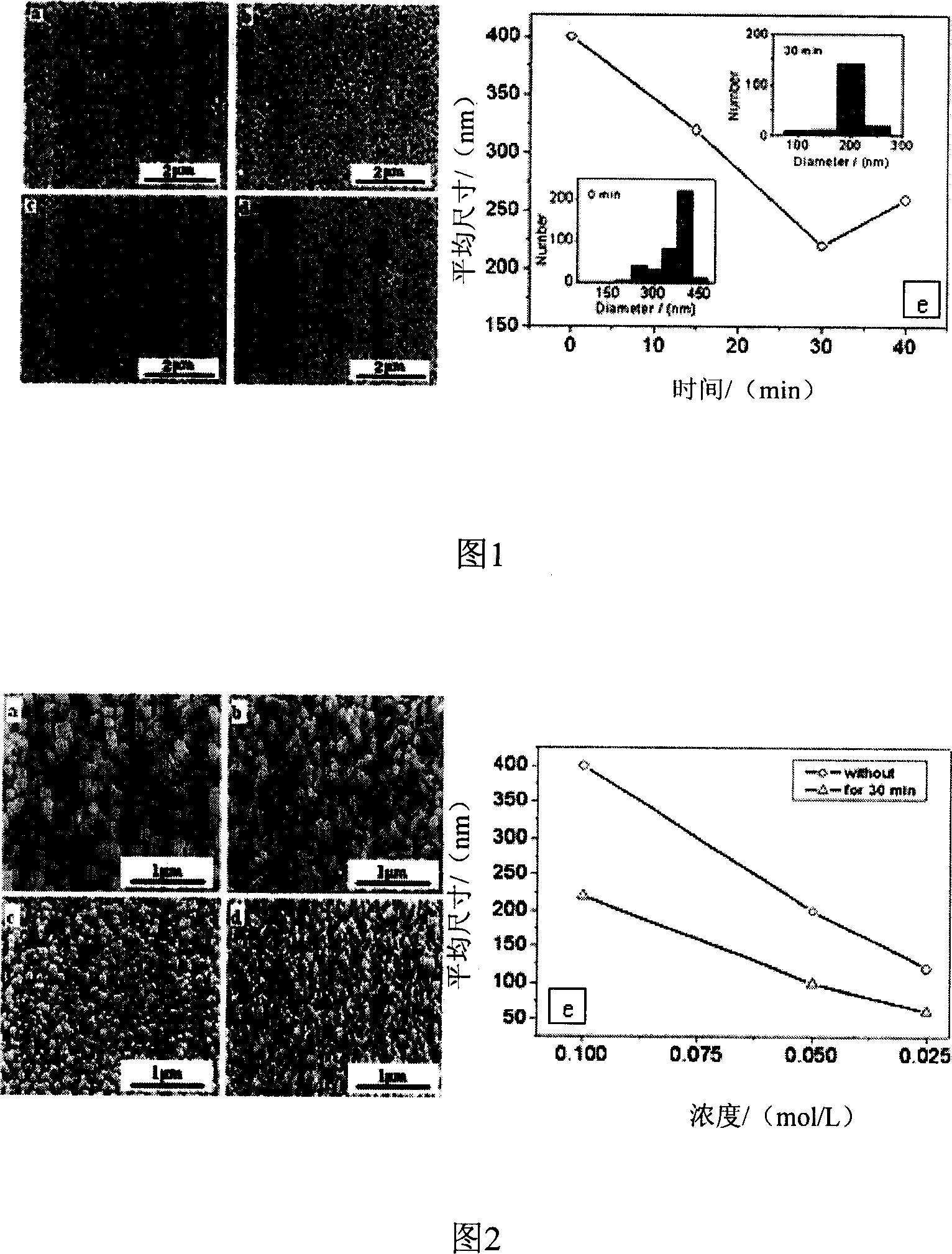

Method used

Image

Examples

Embodiment 1

[0020] The specific steps of the method provided by the present invention are:

[0021] 1) Preparation of ZnO sol precursor: Dissolve 0.36-3.6g of ethanolamine in 50ml of ethylene glycol methyl ether solvent, add 1.09-10.9g of zinc acetate, stir in a water bath at 60°C for 0.5h, and then prepare a 0.1-1M sol precursor body.

[0022] 2) Preparation of ZnO seed layer: after immersing the clean glass substrate in the ZnO sol prepared in step (1) for 1 min, deposit a composite gel layer on the surface of the glass substrate at a pulling speed of 2-6 cm / min , and then heat treatment at 300° C. for 10 minutes, then slowly raise the temperature to 550° C. at 2° C. / min, and keep it warm for 0.5-1 hour to form a transparent ZnO seed layer.

[0023] 3) Preparation of ZnO nanocolumn array growth solution: add 0.37-1.48g of zinc nitrate and 0.175-0.7g of hexamethylenetetramine to 50ml of deionized water to prepare a 0.025-0.1M growth solution, stir well and wait for use.

[0024] 4) Ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com