5-Amide-6-hydroxy-2-(4-carboxylphenyl)benzoxazole salt synthesis method

A p-carboxyphenyl, synthesis method technology, applied in the application field of preparing poly-p-phenylene benzobisoxazole resin, can solve the problems of affecting the molecular weight of PBO, lack of practicability, many reaction steps, etc., and achieve no gas interference and safety hazards, excellent oxidation stability, and high resin intrinsic viscosity

Inactive Publication Date: 2010-08-11

ZHEJIANG UNIV OF TECH +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the method of preparing PBO from MAB solves the main problem of the DAR 2HCl route, the methanol generated at high temperature is mostly removed by forming phosphate ester, and a small amount of methanol gas is still unavoidable. The safety in industrialization Problems still need to be solved; and in the existing MAB preparation method, limited by the solubility of raw material NHAB and MAB itself, the hydrogenation solvent can only select organic solvents (such as DMF, DMAc, DMSO) with strong solvency, but these solvents Both carbonyl oxygen and sulfone oxygen may form hydrogen bond associations with amino and hydroxyl hydrogen in MAB and bring them into MAB products, and most of these residual solvents are polymerization inhibitors of PBO, and are usually difficult to remove

Therefore, the process of preparing PBO by MAB is not ideal at present, and it is necessary to carry out the development of refining technology for the purpose of completely removing PBO inhibition impurities and purification.

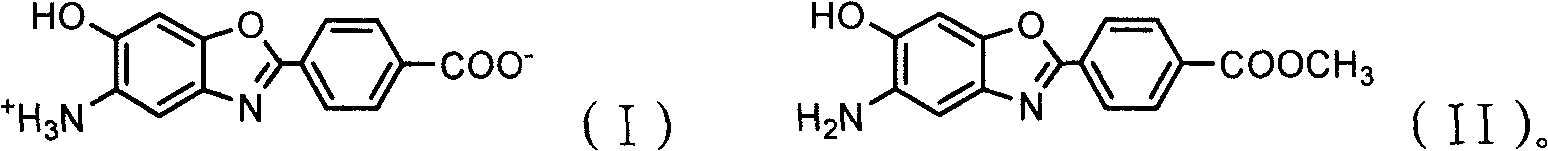

5-Amino-6-hydroxyl-2-(p-carboxyphenyl) benzoxazole carboxyammonium salt (ABAS) belongs to the new monomer of internal salt type AB type PBO. At present, there is no report on its synthesis and application, only similar Acid type AB type PBO monomer 5-amino-6-hydroxyl-2-(p-carboxyphenyl) benzoxazole (ABA), about the synthesis of ABA and its polycondensation to prepare PBO resin, so far there is only one The only report (Polymer preprints, 1990, 31 (2), 681-682), the process route that adopts is as shown in formula (3):

However, the ABA prepared by hydrogenation of formula (3) in DMF solvent also contains PBO inhibitory impurity DMF, which affects the further improvement of PBO molecular weight, making its intrinsic viscosity [η] the highest 12.5dl / g (30 ° C, MSA )

In addition, the reaction steps of preparing ABA with the formula (3) process route are many and the yield is low, and the dehydrating agent trimethylsilane polyphosphate TSPP and the hydrogenation catalyst Pd / C are expensive and consume a lot, plus The first step reaction is carried out in an organic solvent (solvent 1 is o-dichlorobenzene, solvent 2 is ethylene glycol, and DMF, etc.), organic pollution is large, the preparation cost is extremely high and lacks practicability, it is not conducive to the application of preparing PBO and it is difficult Implementation of industrialization

Therefore, the high-cost and high-difficulty preparation technology status of PBO described above has seriously hindered the preparation, expansion and application of high-performance PBO materials, and further improvement and new technology replacement are urgently needed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2~5

Embodiment 6~8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a synthesizing method of 5-amino-6-hydroxy-2-(p-carboxy phenyl) benzoxazole carboxyl ammonium salt (ABAS) and application in the PBO resin, which comprises the following steps: adopting 5-amino-6-hydroxy-2-(p-carboxy phenyl) benzoxazole (MAB) as raw material; hydrolyzing in the solution with alkaline material (alkaline metal carbonate) until the solution is clear at 60-100deg.c protected by inert gas; disposing reacting liquid through sodium bisulfite; evolving crystal as ABAS monomer; setting the weight rate of MAB, alkaline material, putting material in the water at1:1.4-2.0:30-80. The method possesses simple technique and normal equipment to improve product purity over 99%, which shortens polymeric time effectively.

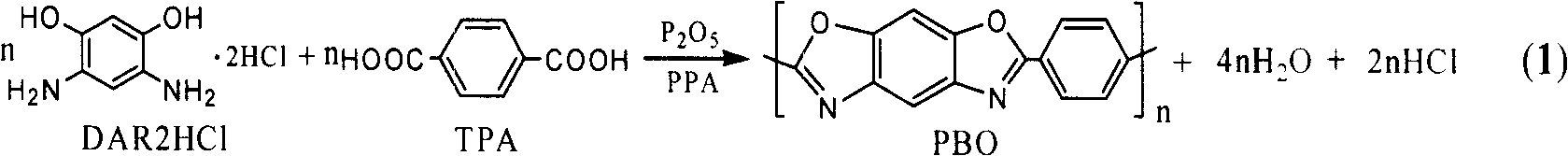

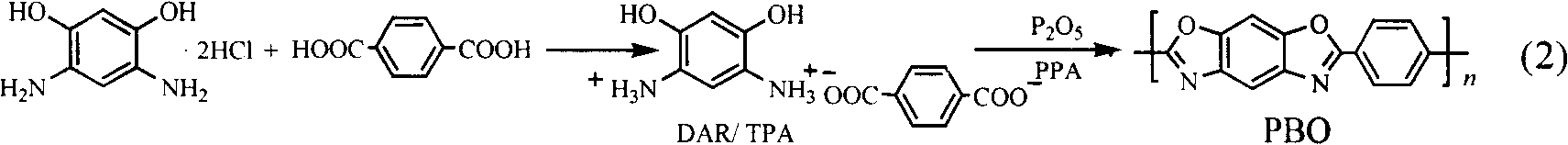

Description

(1) Technical field The present invention relates to a kind of 5-amino-6-hydroxyl-2-(p-carboxyphenyl) benzoxazole carboxyammonium salt (ABAS), its synthesis method and its use in the preparation of poly-p-phenylene benzobisoxazole (PBO ) application in resin. (2) Background technology PBO is the abbreviation of cis-poly(p-phenylene-2,6-benzobisoxazole), which is the most organic and inorganic fiber by polymer liquid crystal spinning technology. High Performance Fiber - Zylon. Research so far, Japan Toyobo (Toyobo) company patent (patent open 2000-38371) under high shear conditions through (1) formula by 4,6-diaminoresorcinol hydrochloride (DAR) and hydroquinone Formic acid (TPA) polycondensation reaction to obtain PBO resin: Although the obtained Zylon-HM type PBO fiber has exhibited very excellent physical, chemical and mechanical properties, its production equipment requirements are very high, and the process condition control is extremely harsh, which is difficult to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D263/57C08G73/22

Inventor 金宁人张燕峰刘晓峰张建庭王小辉宫经会王学杰

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com