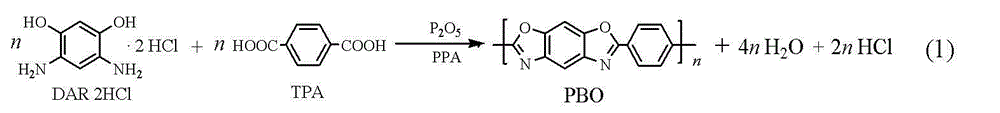

Preparation method of 4-(5-amino-6-hydroxy-2-benzoxazolyl) benzoic acid (ABA)

A technology of benzoxazolyl and benzoic acid, which is applied in the field of preparation of 4-benzoic acid (ABA), can solve the problems of PBO polymerization degree restriction, polymerization process hindered, difficult to achieve equivalence ratio, etc., to reduce sodium ion content , improve polymerization efficiency, and facilitate the recovery of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of 4-(5-amino-6-hydroxyl-2-benzoxazolyl)benzoic acid (ABA)

[0044] Add 12g (0.038mol) methyl 4-(5-nitro-6-hydroxy-2-benzoxazolyl)benzoate (MNB), 306g methanol, 45g water and 5.36g (0.096mol) to the reaction vessel KOH, stirred and heated to 75°C and refluxed, the material changed from a yellow suspension to a red floc, and continued to react for 1 hour. Then put in 1.2g of ferrous chloride, 2.4g of activated carbon, 10.2g (0.163mol) of 80% hydrazine hydrate in turn, raise the temperature to 75°C for reflux reaction for 2h, the reaction solution turns orange yellow, filter while hot to remove the waste carbon, and add the filtrate dropwise 19g of concentrated hydrochloric acid precipitated a yellow solid, filtered, washed with water, and dried in vacuo to obtain 9.52g of the product ABA, with a purity of 96.2%, metal ions (K + , Fe 2+ ) The total content is 3252ppm, and the yield is 92.25%.

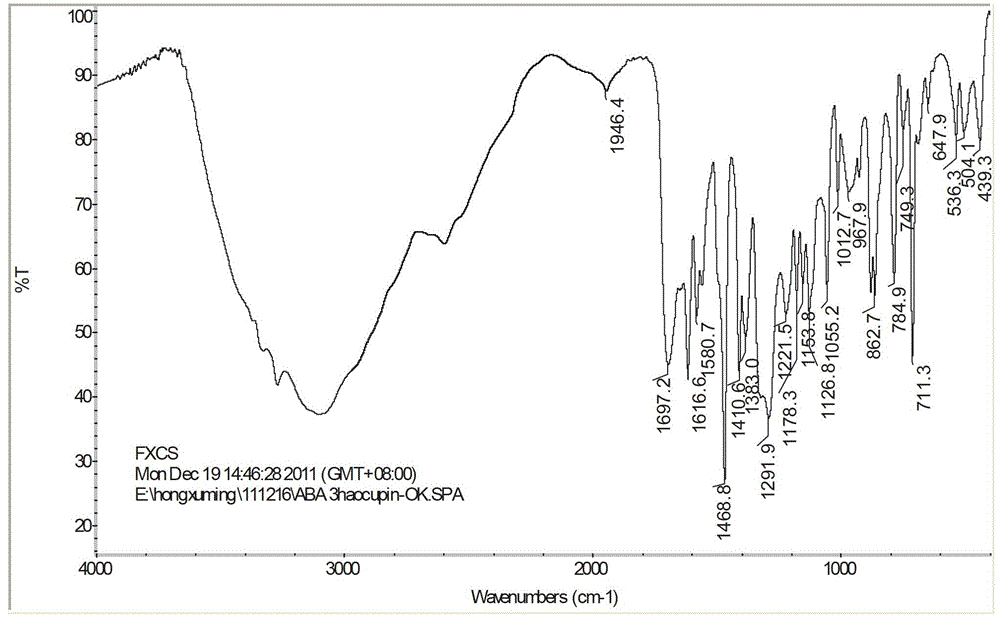

[0045] Product characterization:

[0046] 1 H-NMR ...

Embodiment 2~7

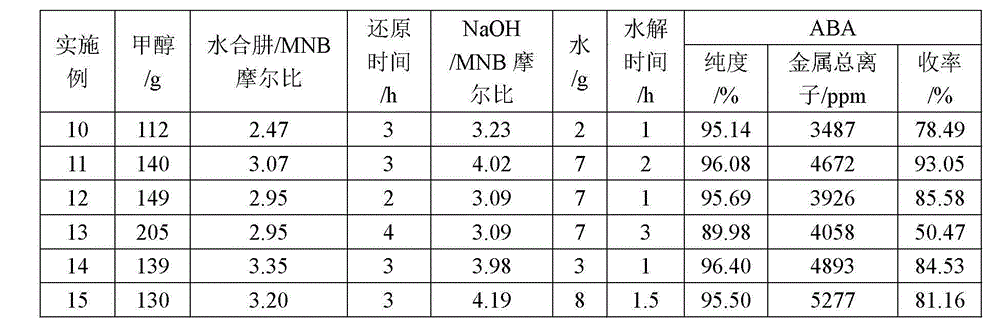

[0049] Embodiment 2~7: the preparation of ABA

[0050] Adopt 12 g MNB and 10.2g 80% industrial hydrazine hydrate to feed and operate similarly to Example 1, get different parameters (methanol, water, KOH, hydrochloric acid consumption) to prepare ABA according to the parameter range described in the present invention, the results are shown in Table 1 :

[0051] Table 1 Preparation of ABA monomer from MNB by KOH hydrolysis followed by hydrazine hydrate reduction "one-pot method"

[0052]

Embodiment 9

[0059] Embodiment 9: Preparation of ABA

[0060] Add 10g (0.032mol) 4-(5-nitro-6-hydroxy-2-benzoxazolyl) methyl benzoate (MNB), 1.98g activated carbon, 1.4g ferric chloride, 5.9g (0.094mol) 80% hydrazine hydrate and 202g methanol, stirred and heated to reflux reaction for 3.5h, the material changed from yellow to brown, then added 4.95g (0.12mol) NaOH and 8g water to the reaction vessel for 3h, the material dissolved into Orange yellow, filter while hot to remove waste carbon, add concentrated hydrochloric acid dropwise to the filtrate to pH=6~7, a yellow solid precipitates, filter, wash with water, and dry in vacuum to obtain 6.35g of the product ABA, with a purity of 95.34%, metal ions (Na + , Fe 2+ ) The total content is 4415ppm, and the yield is 73.84%. The infrared spectrum of the product obtained is identical to the infrared absorption of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com