Ultraviolet cut material, ultraviolet cut filter, discharge lamp and lighting apparatus

A technology for cut-off filtering and ultraviolet light, which is applied to lighting devices, lighting device parts, gas discharge lamp parts, etc. It can reduce problems such as UV damage, prevent damage to organisms caused by UV rays, improve UV light absorption characteristics, and increase temperature dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

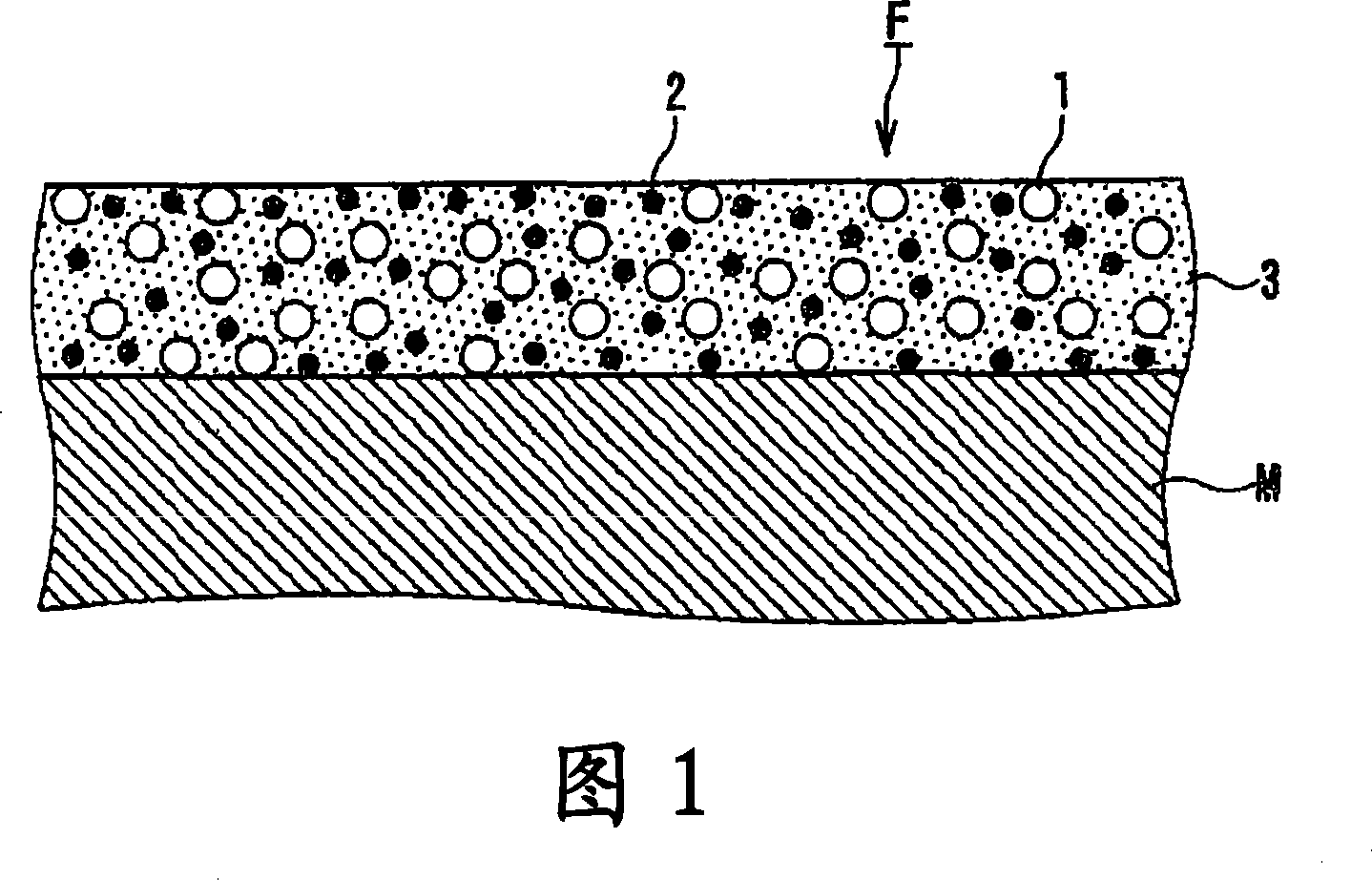

[0082] Fig. 1 shows a first embodiment of the present invention, and is a schematic cross-sectional view of an ultraviolet cut filter formed using an ultraviolet cut material.

[0083] The ultraviolet cut filter F includes a light-transmitting substrate M made of hard glass and a filter film, and the filter film is made by making In-doped zinc oxide as an ultraviolet cut material (ZnO) particles 1 and cerium oxide (CeO 2 ) particles 2 dispersed on the surface of the substrate M. The filter film has a film thickness of 1.0 to 5.0 μm, and zinc oxide particles 1 and cerium oxide particles 2 are dispersed at a molar ratio of about 50:50.

[0084] The zinc oxide particle 1 has a wurtzite crystal structure and contains a solid solution doped with 10% by weight of indium (In). The average particle diameter of the zinc oxide fine particles 1 is 50 to 150 nm, and the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com