Phase change energy stored microcapsule, preparation method and apparatus

A phase-change energy storage and phase-change material technology, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problem of poor chemical stability and thermal stability of microcapsules, complex operation process, and low mechanical strength and other problems, to achieve the effects of easy industrialization, broadening the scope of application, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Sodium alginate solution configuration

[0042] Heat and dissolve 3 parts by mass of sodium alginate, 98 parts of water and 1 part of Tween-80 in a water bath at a temperature of 45°C, and stir with a magnetic stirrer. After the solution is completely dissolved and the solution has a certain viscosity, stop stirring for use.

[0043](2) Phase change energy storage paraffin dispersed in sodium alginate solution

[0044] Melt the phase-change energy storage paraffin into a liquid state in a water bath at 45°C, then take it out, mix it with sodium alginate solution at a mass ratio of 1:4, stir rapidly at 1200r / min, and obtain a uniform O / W type emulsion.

[0045] (3) Encapsulation and curing

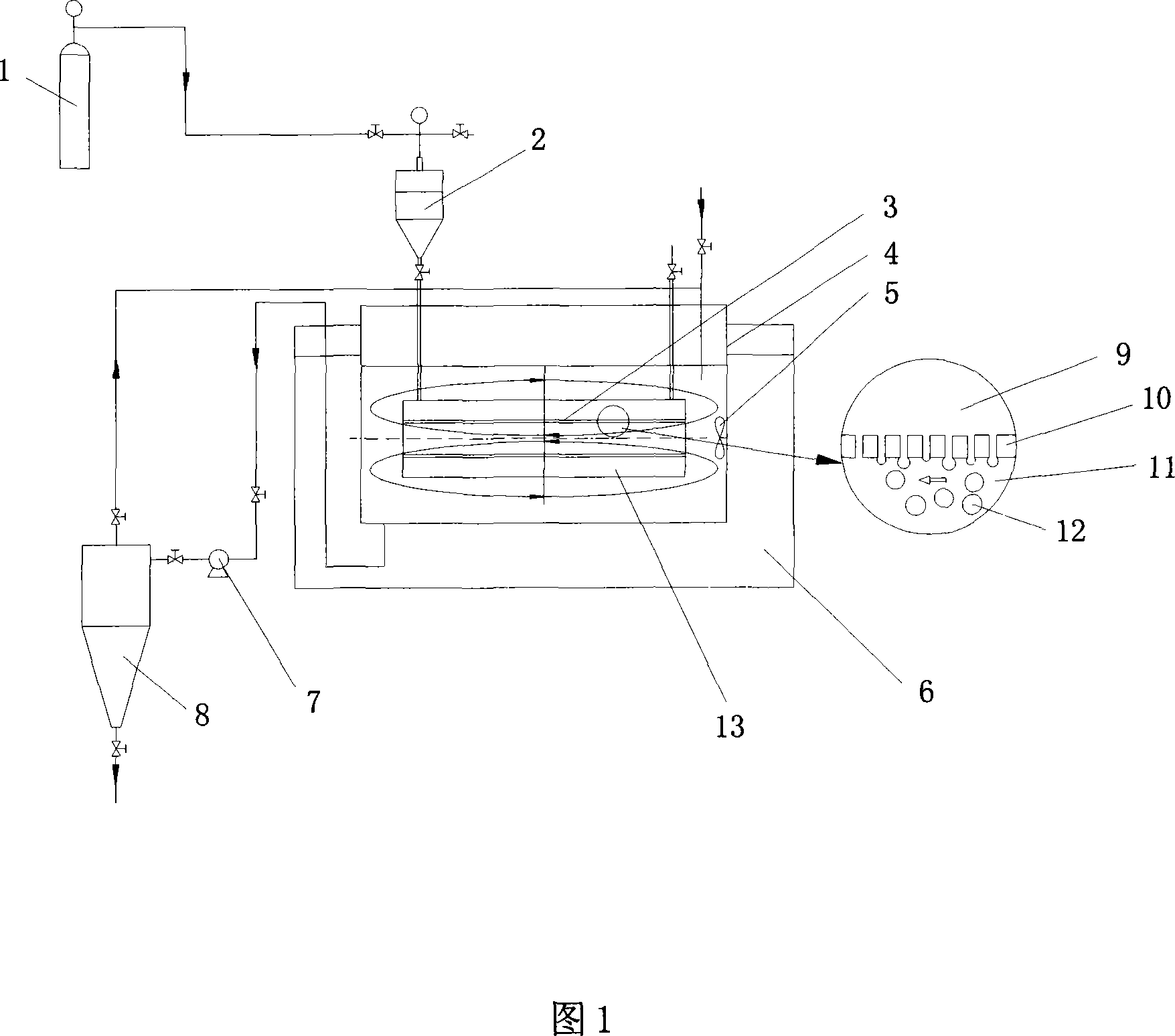

[0046] The emulsion that obtains in the step (2) is packed in the storage tank 2 of device shown in Figure 1, open nitrogen tank 1, make pressure in the storage tank 2 be 1.2atm, after opening circulation pump 5, suction pump 7, Open the valve on the circuit, the emulsion ent...

Embodiment 2

[0049] (1) Sodium alginate solution configuration

[0050] Heat and dissolve 4 parts of sodium alginate, 94 parts of water and 2 parts of Tween-80 in a water bath at a temperature of 50°C, and stir with a magnetic stirrer. After the solution is completely dissolved and the solution has a certain viscosity, stop stirring for use.

[0051] (2) Phase change energy storage paraffin dispersed in sodium alginate solution

[0052] Melt the phase-change energy storage paraffin into a liquid state in a water bath at 50°C, then take it out, mix it with sodium alginate solution at a ratio of 1:3, stir rapidly at 1000r / min, and obtain a uniform O / W type lotion.

[0053] (3) Encapsulation and curing

[0054] The emulsion that obtains in the step (2) is packed in the storage tank 2 of device shown in Figure 1, open nitrogen tank 1, make pressure in the storage tank 2 be 1.2atm, after opening circulating pump 5, suction pump 7, Open the valve on the circuit, the emulsion enters the 0.25m...

Embodiment 3

[0057] (1) Sodium alginate solution configuration

[0058] Heat and dissolve 5 parts of sodium alginate, 90 parts of water and 3 parts of Tween-80 in a water bath at a temperature of 48°C, and stir with a magnetic stirrer. After the solution is completely dissolved and the solution has a certain viscosity, stop stirring for use.

[0059] (2) Phase change energy storage paraffin dispersed in sodium alginate solution

[0060] Melt the phase-change energy storage paraffin into a liquid state in a water bath at 48°C, then take it out, mix it with sodium alginate solution at a ratio of 1:5, and stir rapidly at 1500r / min. After about 40 minutes, a uniform O / W type lotion.

[0061] (3) Encapsulation and curing

[0062] The emulsion that obtains in the step (2) is packed in the storage tank 2 of device shown in Figure 1, open nitrogen tank 1, make pressure in the storage tank 2 be 1.2atm, after opening circulation pump 5, suction pump 7, Open the valve on the circuit, the emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com