Pre-treatment method for sea salt water

A pretreatment, salt water technology, applied in seawater treatment, ion exchange water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex system, waste of resources, inability to low cost, etc., to simplify the process flow , the effect of reducing the desalination cost and reducing the investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

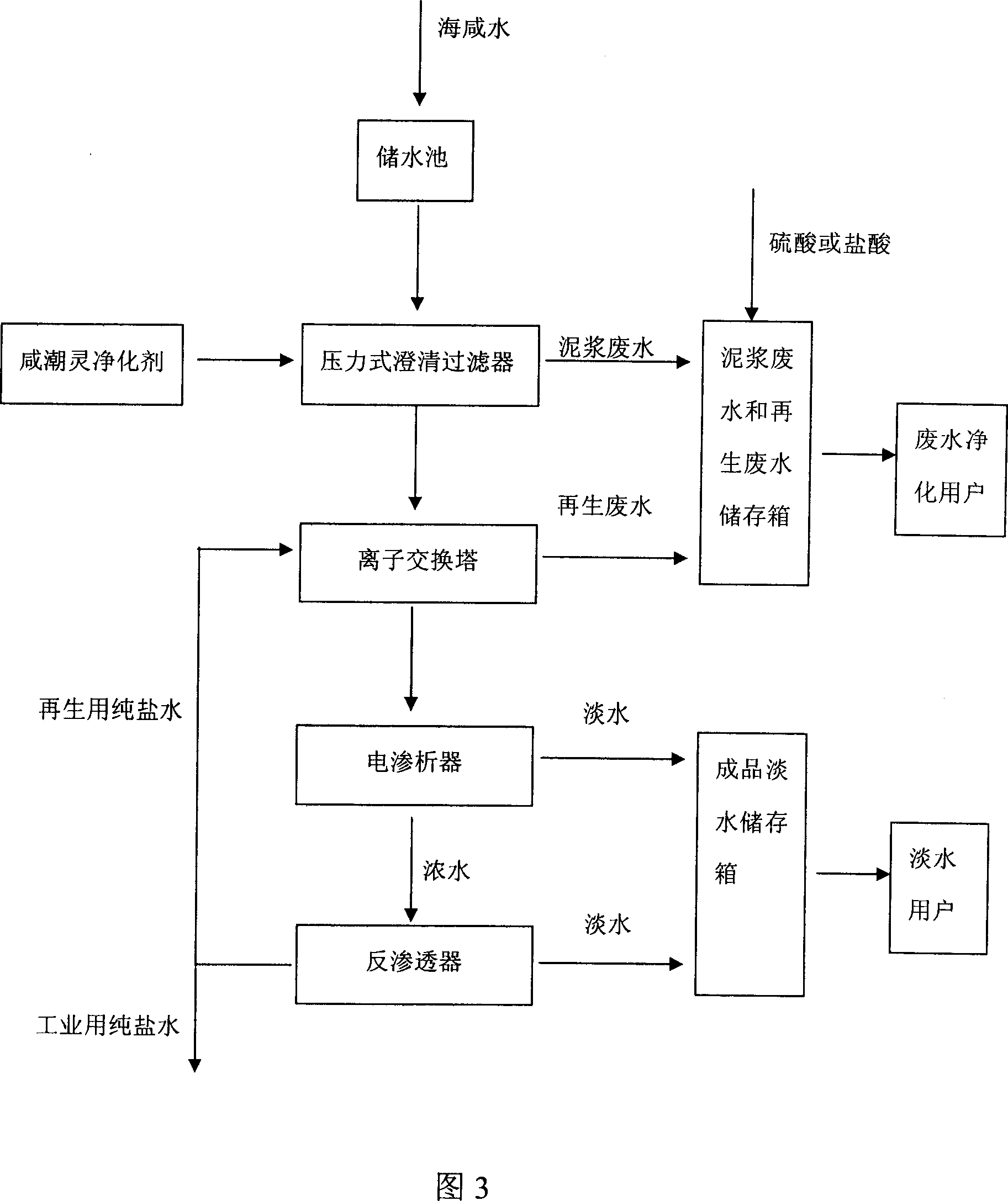

[0039] The following is an example of a system with a treatment capacity of 10 tons of sea salt water to illustrate the specific implementation of the present invention, which is especially suitable for the treatment of coastal and inland river water sources affected by sea salt tides, commonly known as salt tide water.

[0040] According to the technological process shown in Figure 3, assemble the main equipment, instruments, pipe valves, etc.

[0041] device name

Specification

Features

100-200m 3

Storing salty tide water from inland rivers

pressure clarifier

7-13m 3 / hour, water supply pressure 3kg / cm 2

Clarifies, sterilizes, and decontaminates salty tidal water

substances, removal of some fouling compounds

Cationic resin 600 liters

Further purification of salty tidal water into pure NaCl salt

water

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com