Anti scraping optical film containing enen size organic particles

A technology of organic particles and optical films, applied in optics, optical components, nonlinear optics, etc., can solve the problem that the luminance performance is not enough to make it suitable for liquid crystal display applications, affect the diffusion film coating processability, light diffusion effect, diffusion Insufficient cross-linking degree of particles and other problems, to achieve good optical properties and practicability, reduce waste of light sources, and prevent unstable optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] UV curable resin formula A preparation: take a 250 ml glass bottle, add 40 grams of toluene solvent into the glass bottle. Add acrylate monomers in sequence under high-speed stirring: 10 grams of dipentaerythritol hexaacrylate, 2 grams of trimethylolpropane triacrylate, 14 grams of pentaerythritol triacrylate, oligomers: 30 grams of aliphatic urethane hexaacrylate Acrylate [Etercure 6145-100, Eternal Company], photoinitiator: 4 grams of 1-hydroxycyclohexyl phenyl ketone, and finally foamed into about 60% solid content and about 100 grams of UV curable resin formula A in total weight.

preparation example 2

[0071] UV curable resin formula B preparation: take a 250 ml glass bottle, add solvent: 34 grams of toluene and 6 grams of methyl ethyl ketone into the glass bottle. Add acrylate monomers in sequence under high-speed stirring: 16 grams of dipentaerythritol hexaacrylate, 2 grams of trimethylolpropane triacrylate, 20 grams of pentaerythritol triacrylate, oligomer: 18 grams of aliphatic urethane hexaacrylate Acrylate [Etercure6112-100, Eternal Company], photoinitiator: 4 grams of 1-hydroxycyclohexyl phenyl ketone, and finally foamed into about 60% solid content and about 100 grams of UV curable resin formula B in total weight.

preparation example 3

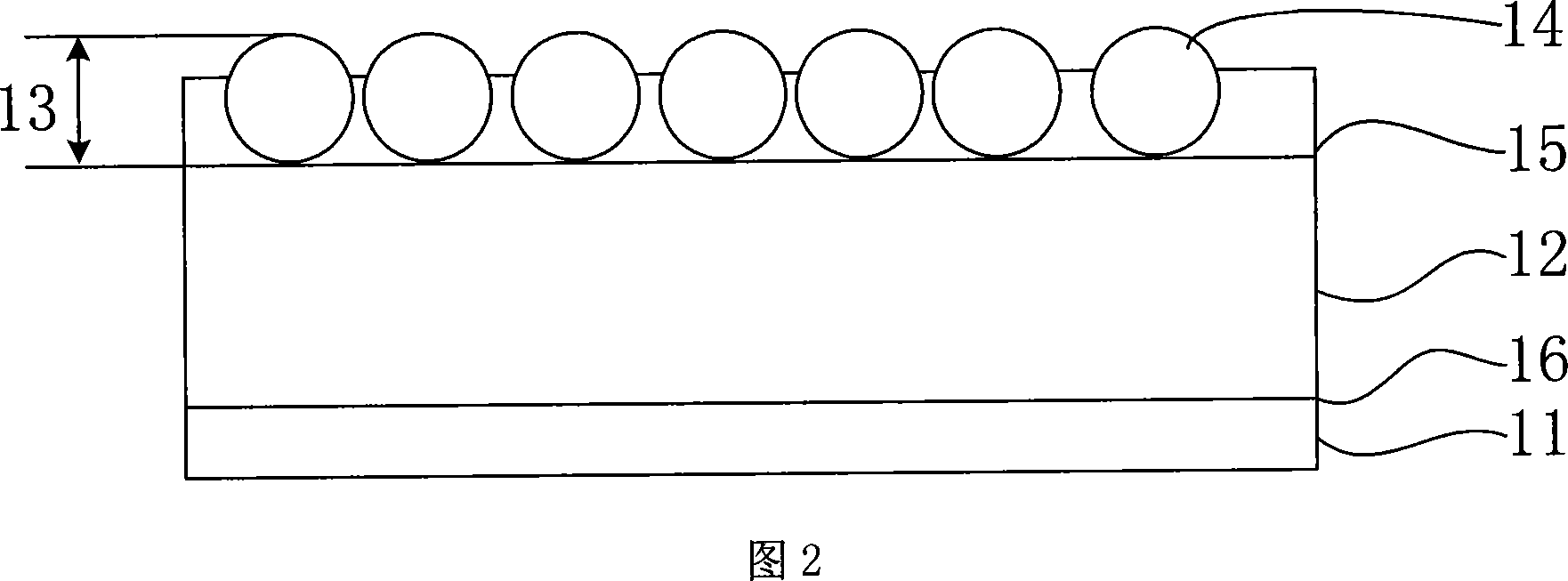

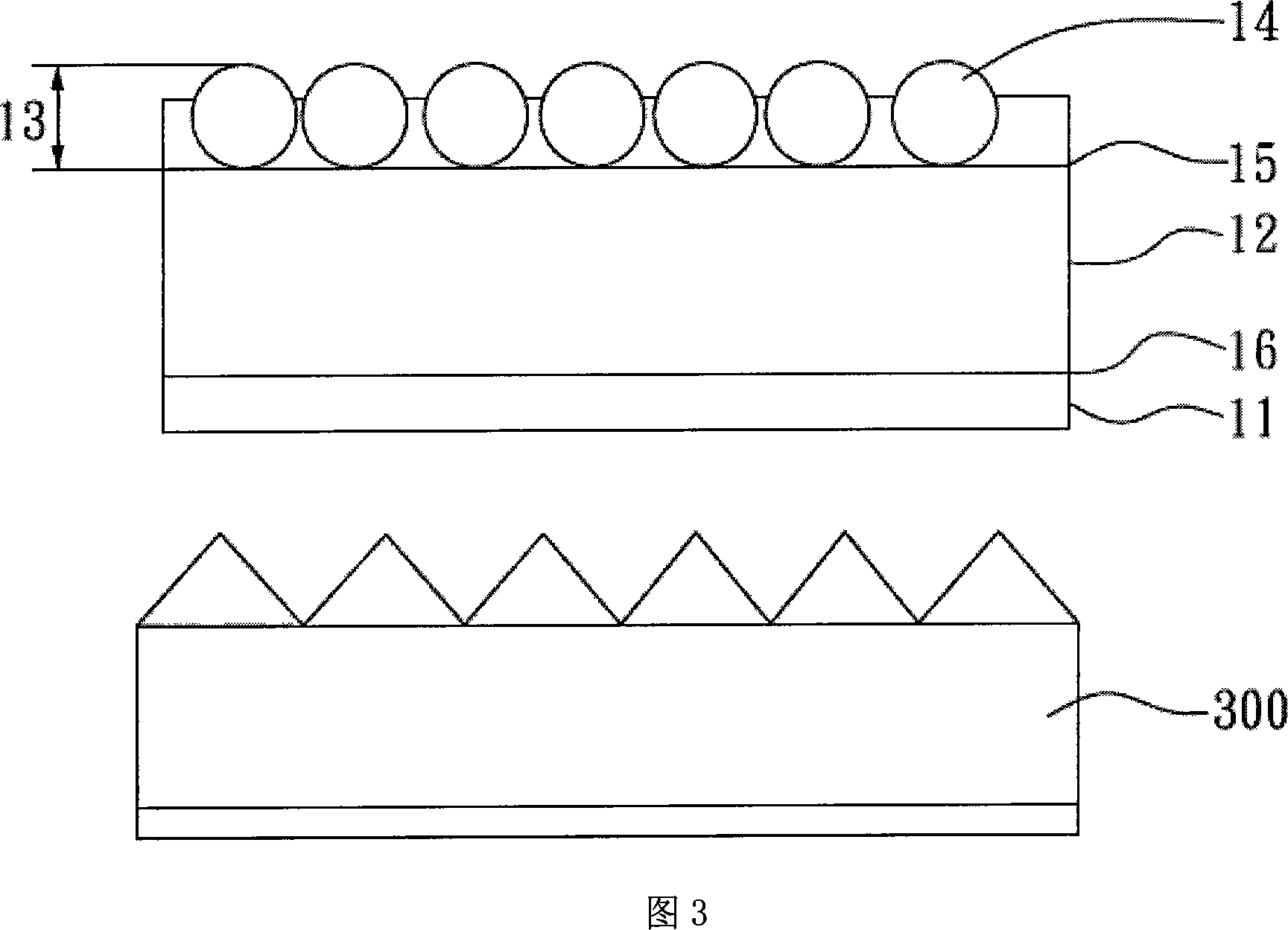

[0073] First hard mask layer (diffusion layer)

[0074] Take a 250 ml glass bottle, and add solvents: 24 grams of toluene and 8 grams of butanone into the glass bottle. Add 4 grams of acrylic microparticles [SSX-108, Japan Sekisui Company] [SSX-108, Japan Sekisui Company] [from methyl methacrylate and ethylene glycol dimethacrylate with a weight ratio of 50:50] under high-speed stirring. High cross-linking organic particles formed by ester monomer; particle size is 8 μm ± 5%], 40 grams of preparation example 1 ultraviolet curable resin formula A (about 60% of solid content, Eternal company), thermosetting resin: 20 grams of poly Methacrylic acid polyol resin [Eterac 7361-ts-50, Eternal company] (solid content about 50%), then add 2 grams of hardener [Desmodur 3390, Bayer company] (solid content about 75%), 2 grams of antistatic Agent [GMB-36M-AS, Marubishioil Chem.Co., Ltd] (about 20% solid content), and finally foamed into about 40% solid content and a coating with a total w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com