Method for the preservation of biological activity of activity polypeptides agent which is made from plants and is took orally for reducing blood suger

A technology of active polypeptide and biological activity, which is applied in the field of preservation of oral biological activity of plant-derived hypoglycemic active polypeptide, can solve problems such as loss of biological activity, and achieve the effects of stable quality, scientific and practical method, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

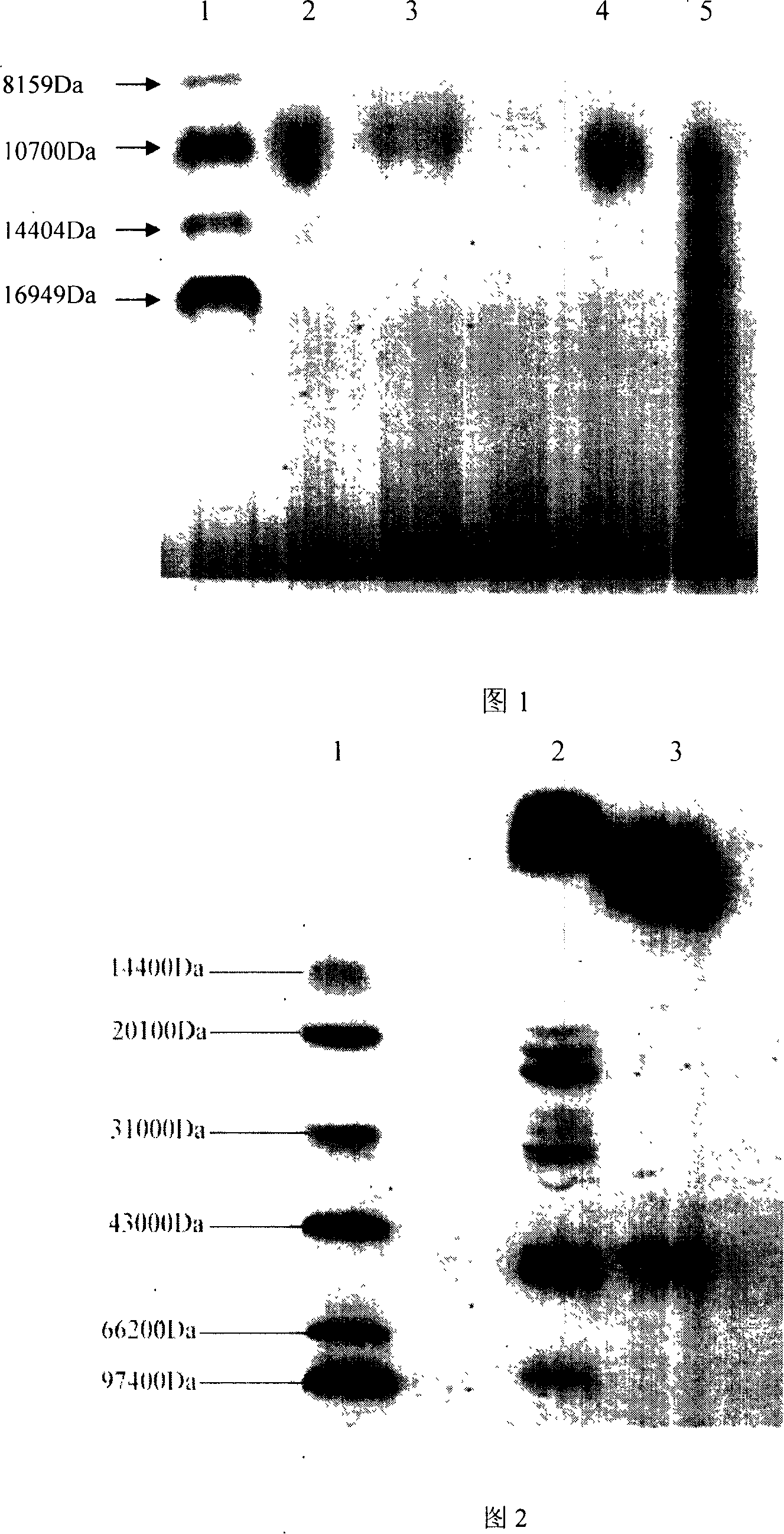

[0020]Example 1: Break bitter gourd seeds together with their shells into 100-mesh granules, add them to ethanol whose pH has been adjusted to 1-2 with hydrochloric acid in a ratio of 1:2~1:8, and stir slowly at 4°C Extract overnight; the next day, centrifuge on a J2 high-speed refrigerated centrifuge at 10000 rpm for 15 min, collect the supernatant, and combine the supernatant; adjust the pH to 2 to 5 with NaOH, and stand for 4 to 6 hours, then at 10000 rpm , 15min centrifugation to collect the precipitate, add acetone to the supernatant at a ratio of 1:2 to 1:8, after standing for 4-6 hours, centrifuge at 10000rpm, 15min to collect the precipitate; weigh the precipitate with 0.01M Tris- The HCl buffer is dissolved, and the chromatographic separation is performed on a G-50 chromatographic column, and the elution peak of the active component is collected and freeze-dried to obtain the active polypeptide component A.

Embodiment 2

[0021] Example 2: The bitter gourd seeds were pulverized with a pulverizer, and 2-10 mM ammonium bicarbonate solution (pH 8.0) was added at a ratio of 1:4-1:10 and stirred and extracted overnight; the next day, centrifuged to remove insoluble Precipitate the material (10000rpm, 15min), heat the supernatant to 80-100℃, keep it for 10min, then centrifuge to remove the precipitated material (10000rpm, 15min); then the supernatant is saturated with 20-90% ammonium sulfate Carry out the salting-out fraction, collect the active components, separate the active components on Sephadex G50 by molecular sieve chromatography, collect the active component peaks, and freeze-dry to obtain the active peptide component B.

Embodiment 3

[0022] Example 3: Wash bitter gourd and cut into small pieces, add 0.005M, pH4.0 acetic acid buffer at a ratio of 1:10-1:20 for high-speed homogenization, filter with three layers of gauze to remove the bitter gourd pulp residue ; Then on a J2 high-speed refrigerated centrifuge at 6000rpm, 20min for centrifugation, collect and combine the supernatant, the supernatant is filtered with 0.45mM and 0.22mM microporous membrane, and then ultrafiltration with MWCO30000 ultrafiltration membrane Separate, collect the filtrate, and then use the MWCO 10000 ultrafiltration membrane for ultrafiltration separation; the concentrate is sent to freeze-drying, and the freeze-dried product is reused with a small amount of 0.005M, pH4.0 acetic acid buffer Dissolve, and then separate it on a Sephacryl S100 column equilibrated with the same buffer, collect the active components, and freeze-dry to obtain the active peptide component C; the above MWCO 10000 ultrafiltration filtrate is then used MWCO 3000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com